Hydraulic Wind Turbines

Background

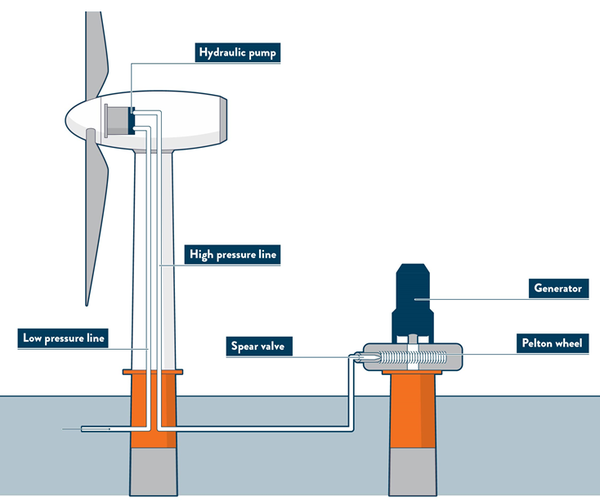

The drivetrain of horizontal-axis wind turbines (HAWTs) generally consists of a rotor-gearbox-generator configuration in the nacelle, which enables each wind turbine to produce and deliver electrical energy independent of other wind turbines. While the HAWT is a proven concept, the turbine rotation speed decreases asymptotically and torque increases exponentially with increasing blade length and power ratings. As offshore wind turbines are getting ever larger, this results in lower rotation speed and higher torque at the rotor axis. The increased loads primarily affect the gearbox, which makes it a maintenance-critical and high-weight component in the turbine. Furthermore, due to the contribution of all components to the total nacelle mass, the complete wind turbine support structure is designed to carry this weight for the entire expected lifetime, which in turn leads to extra material, weight and thus total cost of the wind turbine. As hydraulic transmission systems are generally used in high-load applications and have the advantage of a high power-to-weight ratio, integration in offshore wind turbines seems to be an interesting opportunity.

Goal/ objective

A novel and patented hydraulic concept, that only requires a single water pump directly connected to the turbine rotor, is the Delft Offshore Turbine (DOT). The single water pump replaces high-maintenance components in the nacelle, which in effect reduces the weight, support structure requirements and turbine maintenance frequency. In contrast to conventional wind farms, Delft Offshore Turbines are designed to operate in clusters of multiple turbines, collectively pressurizing sea water to a central multi-megawatt generator platform, where the hydrodynamic energy is converted to electrical energy. The DOT approach has great potential in reducing the amount of components, and thus simplifying maintenance and reducing costs. The concept also enables multiple wind turbines to be controlled collectively.

Work programme

For in-field onshore tests, a Vestas turbine is acquired and its original drivetrain is replaced by a hydraulic drivetrain. This means that the gearbox and generator are removed from the nacelle, and replaced by a single oil pump coupled to the rotor via the main-bearing.

Later tests will involve the inclusion of a regenerative loop for self-sufficient turbine start-up, deployment of the turbine at an offshore location, and the inclusion of an in-house developed low-speed high-pressure sea water pump.

Outcome

During the in-field test, the conventional generator torque control has been substituted by a hydraulic torque control implementation. The hydraulic control strategy is twofold: it is passive in the below-rated region (i.e., a self-regulating control implementation), and active during the transition between below- and above-rated operating conditions. It is shown that by properly choosing the effective nozzle area, while taking into account the efficiency characteristics of all drivetrain components, below-rated tracking of a predefined tip-speed ratio is possible, without the need for active control. For the transition region it is verified that spear valve torque control implementation has sufficient bandwidth to regulate the rotor speed to its rated value.

Project team members

- ir. Sebastiaan Mulders

- Niels Diepeveen (DOT B.V.)

- dr. ir. Jan-Willem van Wingerden

Keywords

Wind turbine control, novel concepts, data-driven optimization

Sponsored by:

TKI Wind op Zee