Discrete Element Modelling to enable Optimal blast furnace Charging [DEM-OC]

Discrete Element Modelling to enable Optimal blast furnace Charging [DEM-OC]

Problem Domain

Operating a blast furnace is finding the right balance between maximizing the reducing gas flowing upwards and decreasing the coke rate on the one hand and keeping the burden descend stable on the other. To achieve this, the permeability has to be optimal as well as the contact between the reducing gas and the iron ore. Therefore, the structure and composition of the packed bed is crucial. The bed is formed with multi-component mixtures of poly-disperse ores, nut coke and additives. These materials significantly differ in nature, shape, size and density.

Therefore, a better understanding of segregation of multi-component mixture will lead increased control of burden charging to increased blast furnace stability, improved permeability allowing for a higher productivity and a lower coke rate. This will result in a reduced cost per ton hot metal of the iron produced.

Goals/Objectives

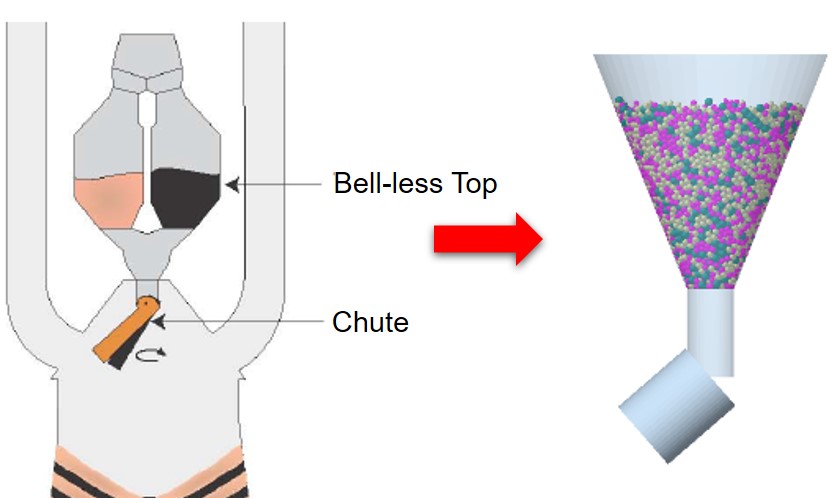

This project aims at establishing a numerical model that captures realistic material and segregation behaviour of multi-component mixtures during charging and burden formation. With the model design and process improvements for optimal charging will be tested.

Key objectives:

1. Characterize the macroscopic behaviour of single and multi-component mixtures

2. Identify segregation mechanisms and characterize segregation sensitivity of multi-component mixtures, taking into account length scales of particles and equipment.

3. Process improvements for optimal charging through segregation control in the virtual environment.

Approach

To achieve the objectives, experimental study for identifying segregation sensitivity of multi-component mixture will be built. Additionally, the DEM model will be designed based on the results of experimental study of mixing of multi-component. Next, the process of charging blast furnace will be modelled using DEM to investigate on the segregation during charging blast furnace. Finally, the guideline for optimal charging through segregation control will be provided with the DEM Model.

Results (or expected results)

The final results will be the guideline for optimal charging blast furnace with respect to segregation control. Currently, the experiment and DEM model have been designed to analyze segregation sensitivity of multi-component mixture. Next, the DEM model for simulating charging blast furnace process will be designed.

[1] Jeseung Moon, Yusong Pang, Allert Adema, Jan van der Stel and Dingena Schott (2019). Blast furnace charging: segregation of multi-component mixtures. Materials Innovation Institute Conference 2019, Noordwijkerhout, The Netherlands.

[2] Jeseung Moon, Yusong Pang, Allert Adema, Jan van der Stel and Dingena Schott (2019). Blast furnace charging: segregation of multi-component mixtures. Blending and Segregation Forum 2019, Enschede, The Netherlands.

[3] Jeseung Moon, Yusong Pang., Allert Adema, Jan van der Stel and Dingena Schott (2020). Segregation sensitivity analysis during discharging hopper base on discrete element modeling. Materials Innovation Institute Conference 2020, online.

[4] Jeseung Moon, Yusong Pang., Allert Adema, Jan van der Stel and Dingena Schott (2021). Segregation of multi-components mixtures in blast furnace: a review. 24th International Congress of Chemical and Process Engineering CHISA 2021, Prague, Czech Republic. will be presented.

Funding

This research is supported by M2i and Tata Steel Europe, the Netherlands. Their support is gratefully acknowledged.

Contact person

Jeseung Moon, MSc. – PhD Candidate

J.Moon@tudelft.nl

Delft University of Technology

Faculty of Mechanical Engineering (Faculty of ME)

Department of Maritime and Transportation Technology (M&TT)

Transport Engineering and Logistics (TEL)

Dr.ir. Yusong Pang - Daily Supervisor

Y.Pang@tudelft.nl

Delft University of Technology

Faculty of Mechanical Engineering (Faculty of ME)

Department of Maritime and Transportation Technology (M&TT)

Transport Engineering and Logistics (TEL)

Dr.ir. Dingena L. Schott - Project Leader

D.L.Schott@tudelft.nl

Associate Professor

Delft University of Technology

Faculty of Mechanical Engineering (Faculty ME)

Department of Maritime and Transportation Technology (M&TT)

Transport Engineering and Logistics (TEL)