Fracture and failure assessment of complex materials

This research theme focuses on identifying fundamental mechanisms of fracture in complex multiphase materials. The aim is to understand damage evolution as well as failure initiation and provide relation to microstructure, performance and reliability of modern materials and components made from them. The effect of material processing as well as new methods for performance characterization are also investigated.

Current research projects:

A1. Effect of microstructure of fracture toughness of welded thick section high strength steels

One of the most significant problems associated with the implementation of high strength steels for offshore applications lies with the guarantee of welded joint reliability. An experimental study combining microstructural investigations with a new adjusted sub-sized CTOD test is conducted in order to assess the fracture toughness in the heat affected zone (HAZ) of welds on high strength steels. Emphasis is placed on the coarse grain HAZ and the effects of variations in alloying and inclusion content on the microstructure and toughness properties is studied

A2. Application of Circumferentially Notched Tension specimen for fracture toughness assessment of high strength steels

The fracture toughness of high strength steels is commonly determined by standard methods using Compact tension (CT) or Single edge notched bend (SENB) specimens. The Circumferentially Notched Tension (CNT) specimen is a potential candidate for determining the fracture toughness of highly constrained cracks, theoretically approaching plane strain conditions, even for small specimen dimensions. The goal of this study is to develop fundamental understanding of CNT methodology and apply it to parent and welded high strength steels.

A3. Materials toughness design through microstructural control

The aim of this project is to establish a framework for the probability of cleavage failure in structures by developing a physically-based statistical relationship between multiple critical microstructural parameters and fracture toughness, based on the scatter of local properties.

Hence, this research will help to reduce full-scale toughness testing and allow for a transition from a “try it and see what happens” to a “predict it and control what happens” approach.

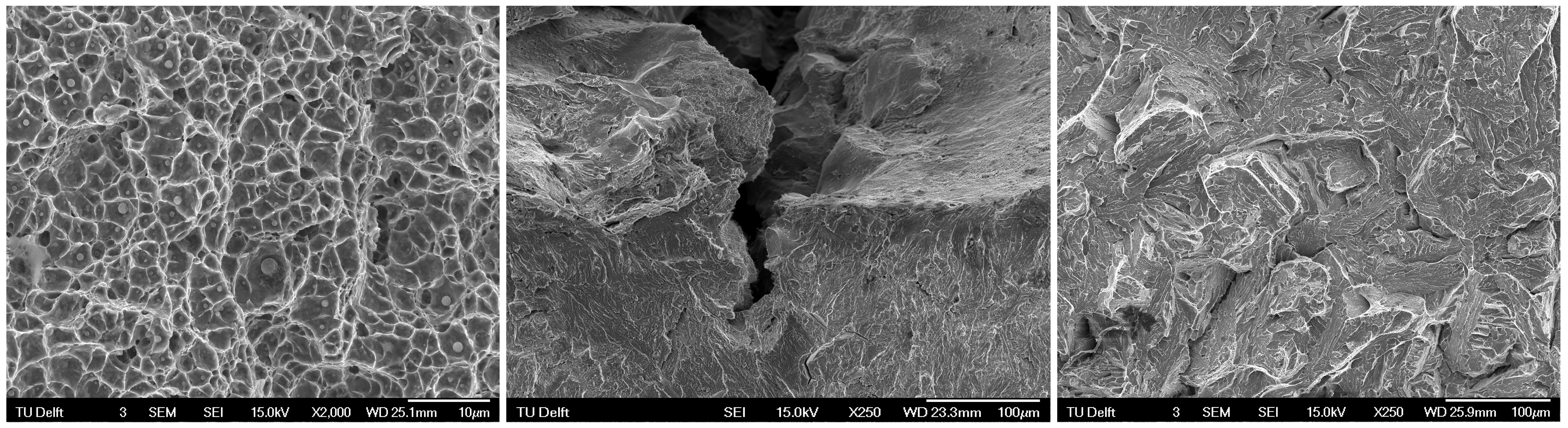

A4. Thermomechanical fatigue of cast irons

This research direction focuses on identifying the mechanisms of thermomechanical fatigue crack growth in graphitic cast irons. The aim is to understand the crack initiation and propagation processes, taking into account applied conditions such as temperature range, mechanical constraint and strain holds and microstructural effects like delamination of graphite particles and metallurgical processes taking place in different cast-iron matrices. Advanced techniques to describe the combined effect of fatigue and time-dependent deformation (e.g. by recovery and/or creep) is also part of this research.