Engineering & Systems

‘Connect for Continuous Care’

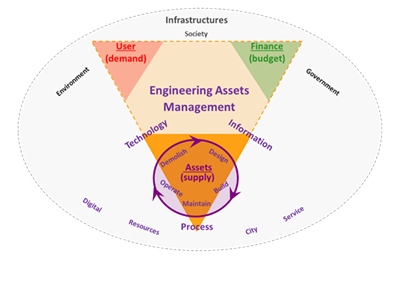

Engineering Asset Management (EAM) is dedicated to the development and application of engineering and managerial solutions to make physical assets as part of (public) infrastructures safe, effective, efficient and environmentally-friendly. EAM is all of the activities and processes used to ensure that new and existing assets provide balanced performance levels, for a specified time frame, accounting for the entire life-cycle phases: Design, Build, Maintain, Operate and Demolish (DBMOD cycle), see Fig. 1. Thus, it promotes a very multi-disciplinary thinking connecting engineering, economics, organisations etc., to create added value for asset users, owners, managers, service contractors and other stakeholders.

EAM requires taking into consideration the value of these assets, including ecological and social benefits and costs. This requires a dynamic approach integrating engineering assets technology, asset information systems and operational processes. Within this approach, it is essential to balance the (varying) user demands and available financial resources with the supply of effective and efficient engineering assets service levels. To manage these levels, proper tooling, systems and methods are required to analyse, plan & control and forecast accurate service level states of the engineering assets.

Specifically, within the civil construction industry, EAM recently emerged as an important field of research due to the shift from ‘one-time control of new green-field’ build projects towards ‘continuous care of quality of service levels of existing gray-field’ infrastructures, including renovations, re-builts and or modifications. Moreover, this ‘service’ change, drives the following important developments

- effective and efficient interventions and renovations are needed to ensure that existing infrastructures keep on providing adequate service levels with a minimum of service interruptions;

- actual service information and predictions are expected by the rapid development of intelligent monitoring and data analysis capabilities;

- long-term and integrated performance based contracts are common where payments are related to service requirements;

- optimal distribution and allocation of resources (money, equipment and people) within the total service supply chain (owner, provider, operator, government and or (safety) regulator).

All of this requires a continuous cooperation within the supply chain of service provision between asset owners and engineering services contractors over the entire asset life-cycle phases. It is also of importance that the asset performances (‘supply’) are optimally balanced between the user requirements (‘demand’) and the resources c.q. budgets (‘finance’) that are available, see Fig.1. Moreover, asset managers and service contractors realize that they are operating within a challenging and changing environment where the three major societal changes or drivers: i.e., ‘digital’, ‘resources’ and ‘city’, will have a profound impact on different assets as part of infrastructures over the coming decade and will even inter-connect different infrastructures more and more.

First, the digital change is driving transport processes towards more real-time co-ordination of supply and demand with completely new types of asset management practices. Second, the resources change drives towards smart logistics both for providing engineering services and for staff. Third, the city change is driving all major infrastructures competing for space with existing and new spatial uses in the urban environment. All of this leads to connectivity and interface challenges where integral planning should solve these. Last but not least, because of this fast changing world, the future infrastructure systems and their engineering assets should be responsive to these changes for which a connective EAM approach is necessary.

EAM themes and scientific questions

There is a wide variety of scientific questions related to the developments as described above. For reasons of focus, the EAM themes are predominantly related to the engineering asset supply domain, with potentially links to the user or finance domain (see Fig. 1). Moreover, these themes are primarily dealing with quantitative information and or operational process topics. Hence, the three following EAM themes below with associated scientific questions provide a starting point both for research and education (see for more details section 1 and 2).

- Integral Asset Planning (IAP)

How can engineering asset systems be planned in an integral manner with the following dimensions: i.e., 1. Spatial (multi-scale: system, network, object, element, component, material level); 2. Time (multi-scale: weeks, months, years, decades and life-cycle phase: design, build, maintain, demolishment); 3. Measurement (financial performance, physical capabilities, contract goal, safety requirements); 4. Organization (user, owner, provider) 5. Risk (estimate, measure)? Which type (or combination) of modelling technique (Monte Carlo simulation, Dynamic Programming, (semi-) Markov processes, Bayesian networks, decision, Game theory, Real Options, hybrid System Dynamics, Adaptive Pathways, Serious Gaming etc.) is appropriate for the type of scale of the planning model to be developed? Which management and planning strategies including control measures can be proposed to asset managers by using these models? How can we derive a dynamic response functions for infrastructure systems? How can we integrate price uncertainties, successive multiple intervention strategies and managerial flexibility into a next generation of LCC optimisation models for public infrastructures?

- Asset Service Logistics (ASL)

What type of algorithms or techniques are required for asset service logistical support systems that powers: 1. sustainable energy (support) infrastructure 2. city service hubs? For which spatial or time level within the entire supply chain, what type of modelling is most suitable? In which part of the supply chain the uncertainties have to be taking into account by probabilistic scheduling and where can we plan with deterministic values? Which type of automated control techniques are required for the development of virtual scheduling and control assistants? What is the role of expert judgement in asset service logistics and can it be automated within a virtual maintenance assistant? How can a Reversed Logistics service market model for local city-mining enhance the efficiency within the asset re-cycling supply chain? What is the impact of the introduction of vested contracts for asset service levels? How to improve associative contracting to is to optimize the performance goals of each partner within the asset service supply chain?

- Asset Information Systems (AIS)

Looking to all latest data and ICT developments, which possible technologies (e.g. AI, augmented reality, robots) can improve engineering asset management and how should these be adapted to the infrastructure and or the building domain? How can these developments be evaluated? How does the asset management office of the future look like and what is the role of virtual assistants for design, engineering and maintenance in this? How can innovative insights, techniques, virtual support systems and forms of collaboration be used and operationalised? How can structural health monitoring be improved following a data-science approach? What type and which level of asset information is needed for ‘local city-mining’ of recycled materials and what does it mean for existing Building Information Models (BIM)? How can heterogenous information management in scattered enterprise asset management software tooling, including BIM 5D, be optimized? How can we utilise user generated asset information? What can be the role for Serious Gaming, Expert Judgement and virtual maintenance assistants to control engineering assets with long-life spans? Can we improve system safety and system validation by digital-infra-twin models and virtual training concepts for engineering assets, operating software and stakeholder processes (eg. safety officer, tunnel operator, service contractor)? How can actual asset information from ‘outside’, gathered by users and inspectors be linked between asset management offices and what type of techniques should be used for these so-called ‘data-to-xx’ concepts?