Publications

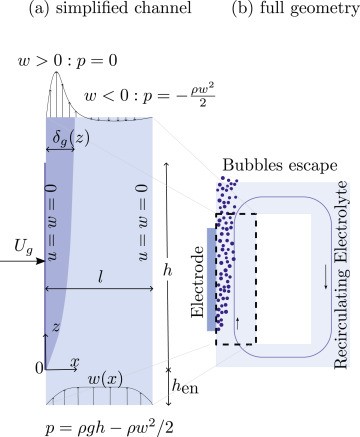

Analytical mass transfer coefficients for natural convection from vertical gas-evolving electrodes

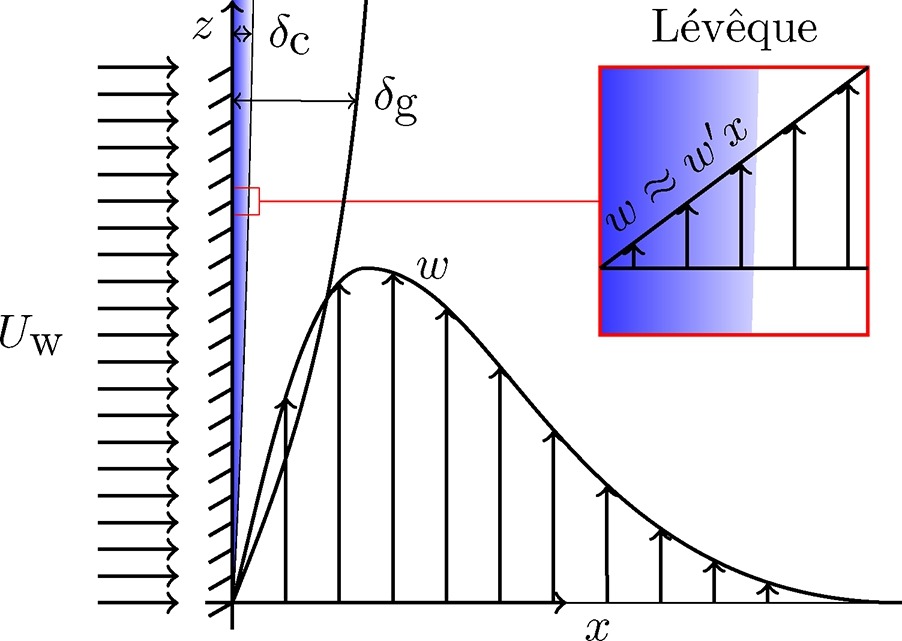

The high mass transfer to or from gas-evolving electrodes is an attractive feature of electrochemical reactors, which can be partly attributed to the large convective flows that arise due to the buoyancy of bubbles. We derive exact analytical expressions for mass transfer coefficients for the case of constant gas flux boundary conditions. For the mass transport both Dirichlet and Neumann boundary conditions are considered. We deploy a recently derived self-similar solution of laminar two-phase flows, with density, hydrodynamic diffusivity, and viscosity dependent on the local gas fraction. Combining this with the Lévêque approximation, new mass transfer coefficients are obtained analytically. These new results are relevant for various electrochemical processes with gas evolution as well as boiling. The new formulation shows the mass transfer coefficient to scale with the vertical coordinate z proportional to z−1/5 for short electrodes and low current densities and z−4/15 for long ones and high current densities. The former limit also applies when buoyancy is due to temperature or concentration differences in the case that density differences are small. We provide a general overview considering all possible gas and mass boundary conditions combinations and a comparison with the Boussinesq approximation of small density differences.

Valle, N., Haverkort, J. W.

Influence of mixing time on a reversal tolerant anode measured ex situ for a PEMFC

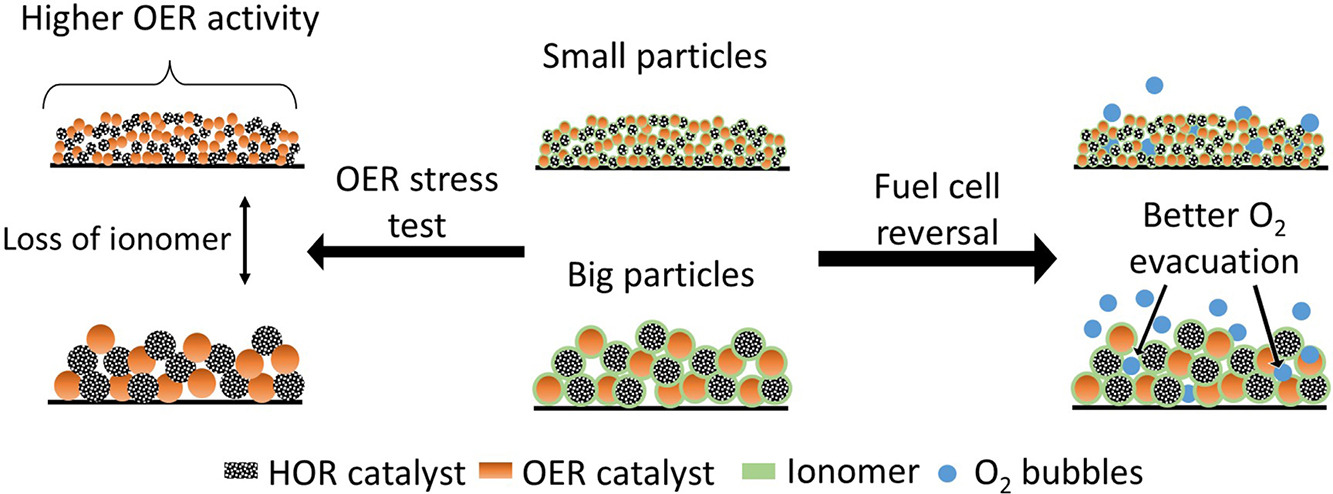

When no hydrogen can reach the Pt catalyst in the anode for the hydrogen oxidation reaction (HOR) of an operating proton exchange membrane fuel cell (PEMFC), the anode potential increases and causes the cell potential to be reversed compared to normal operation conditions. During this reversal, the oxygen evolution reaction (OER) and carbon oxidation reaction (COR) will occur at the anode, where the COR has devastating consequences for the electrode. Introducing an OER catalyst limits the COR to occur, which makes a reversal tolerant anode (RTA). In this research, RTAs are differentiated by applying different ball milling times during catalyst layer processing, forming big and small OER (IrOx/TiOx) and HOR (Pt/C) catalyst particles. The two different particle sizes were electrochemically tested using a rotating disc electrode (RDE). Both catalyst sizes show a decrease in OER activity (mA cm−2) accompanied by loss of the ionomer in a self-developed accelerated stress test (AST). The small particle RTAs show higher OER activity as a result of increased surface area. However, during a chronopotentiometry measurement, which mimics a fuel cell reversal, the small particle coatings show a worse reversal tolerance. This phenomenon can be attributed to the increased difficulty in removing oxygen bubbles.

S.J.T. Homan, K. Aylar, A. Jurjevic, M. Scolari, A. Urakawa, P. Taheri

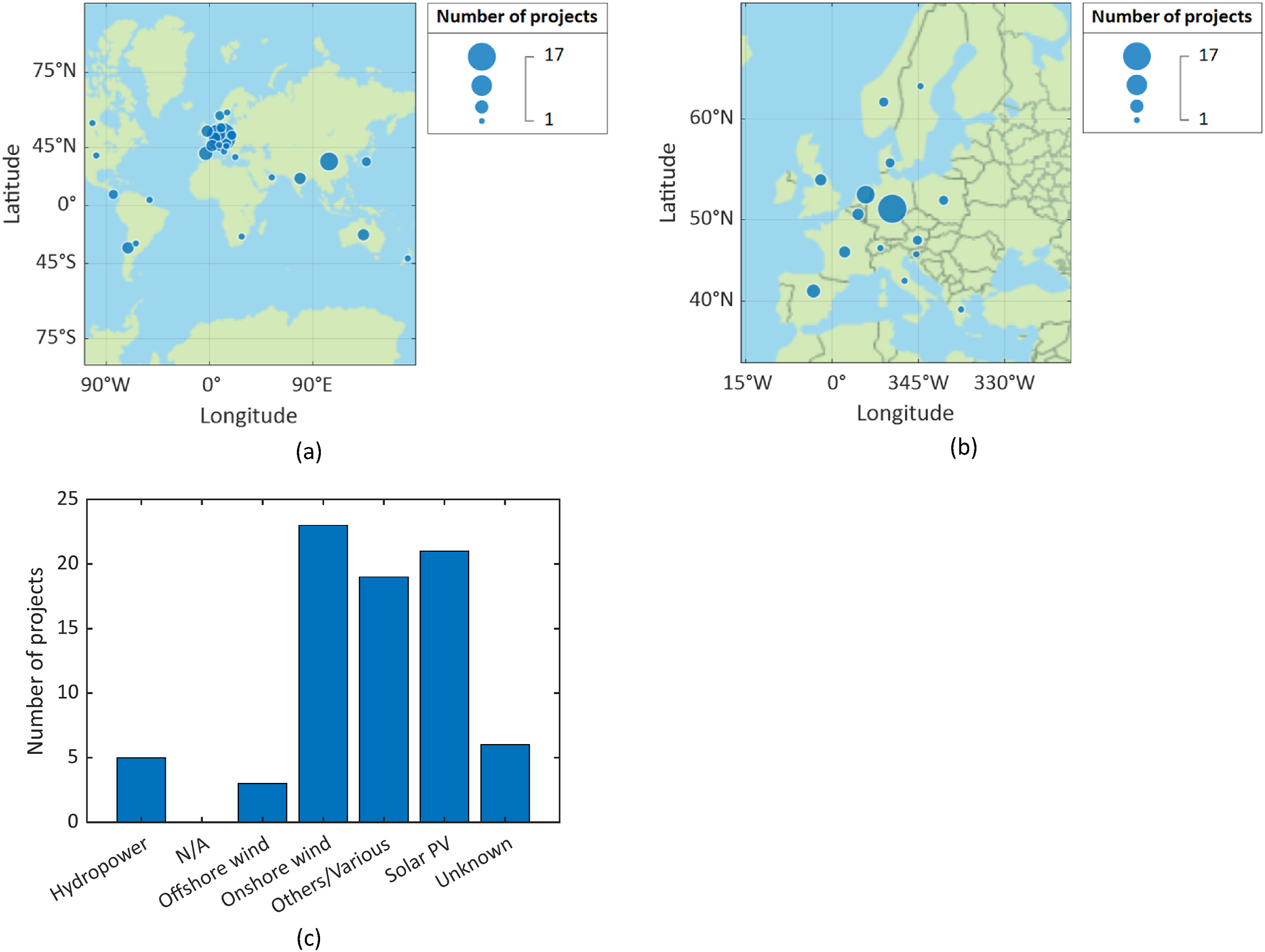

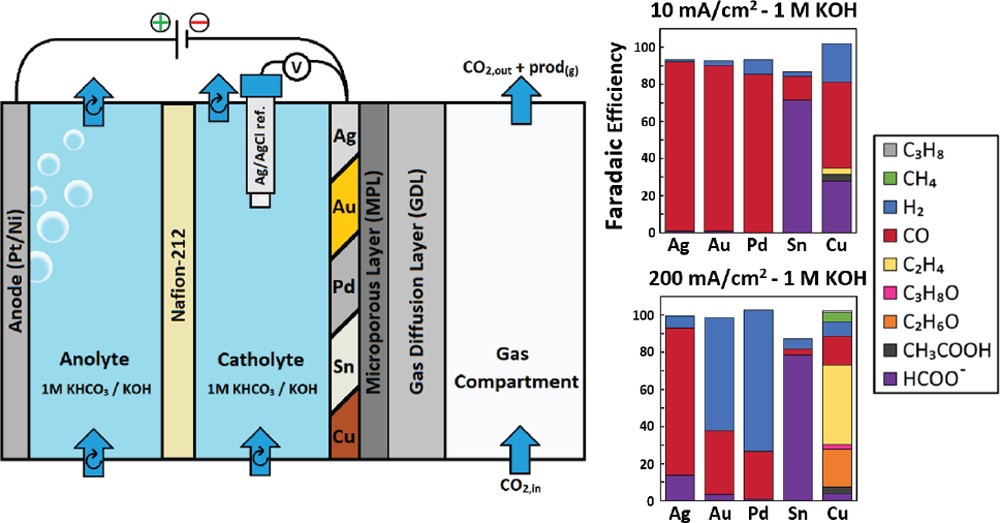

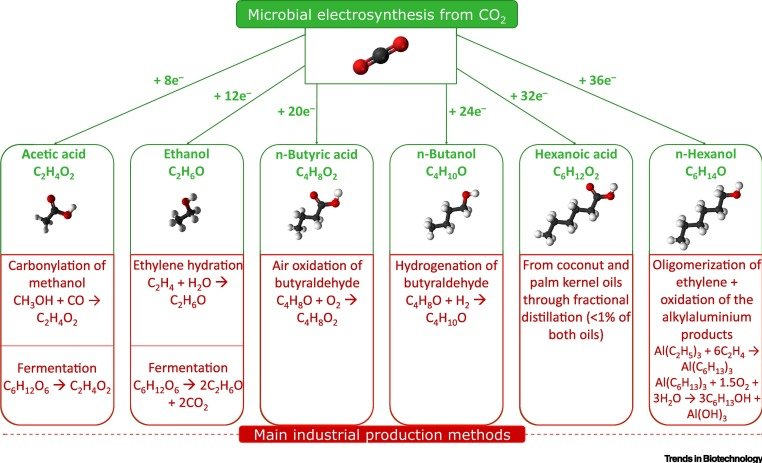

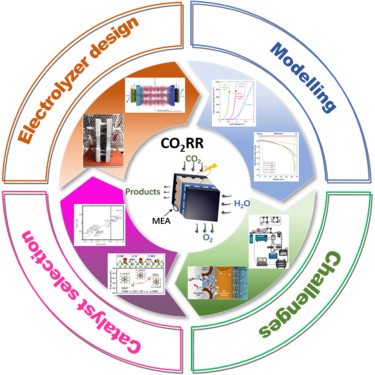

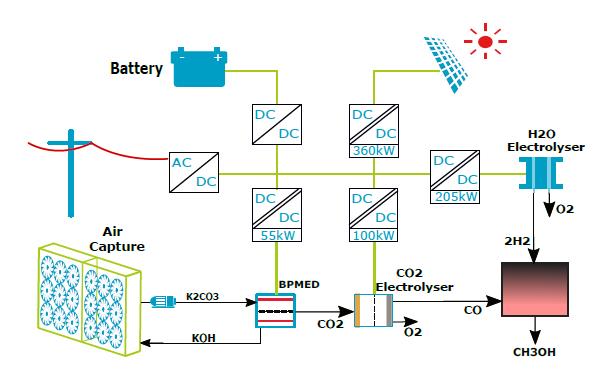

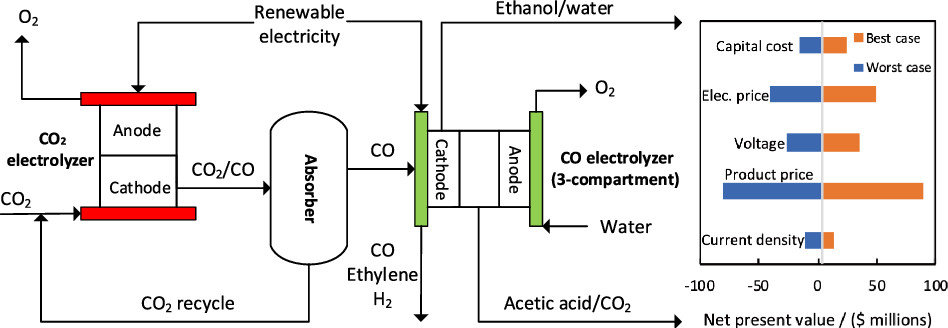

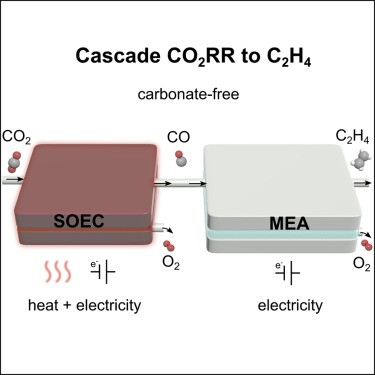

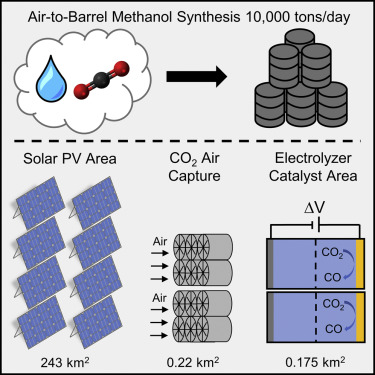

Challenges and opportunities for CO2 electroreduction from a process systems engineering perspective

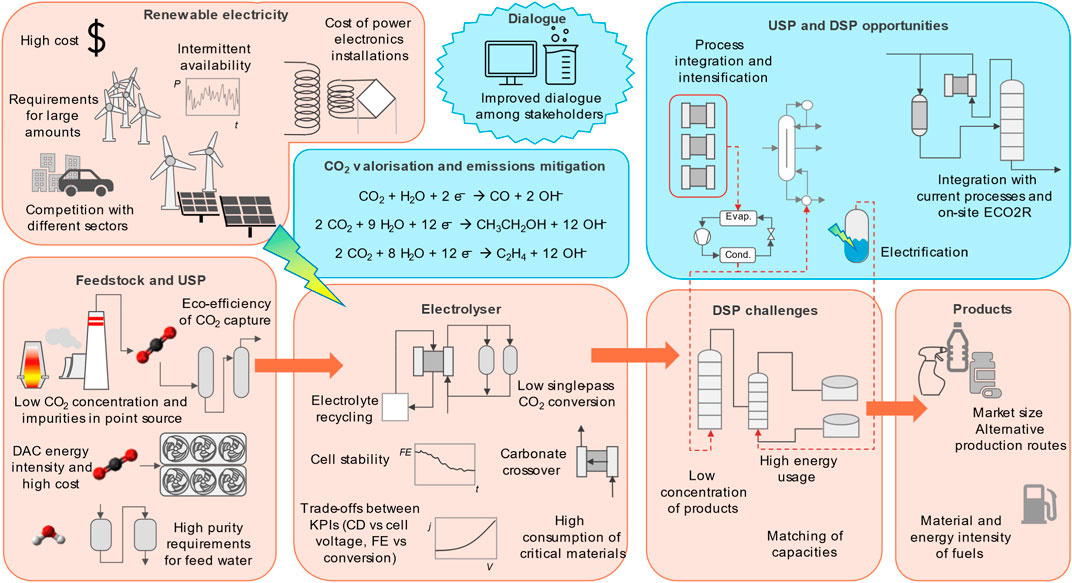

Despite the huge efforts devoted to the development of the electrochemical reduction of CO2 (ECO2R) in the past decade, still many challenges are present, hindering further approaches to industrial applications. This paper gives a perspective on these challenges from a Process Systems Engineering (PSE) standpoint, while at the same time highlighting the opportunities for advancements in the field in the European context. The challenges are connected with: the coupling of these processes with renewable electricity generation; the feedstock (in particular CO2); the processes itself; and the different products that can be obtained. PSE can determine the optimal interactions among the components of such systems, allowing educated decision making in designing the best process configurations under uncertainty and constrains. The opportunities, on the other hand, stem from a stronger collaboration between the PSE and the experimental communities, from the possibility of integrating ECO2R into existing industrial productions and from process-wide optimisation studies, encompassing the whole production cycle of the chemicals to exploit possible synergies.

Riccardo Dal Mas, Ana Somoza-Tornos, Mar Pérez-Fortes, Ruud Kortlever, Anton A. Kiss

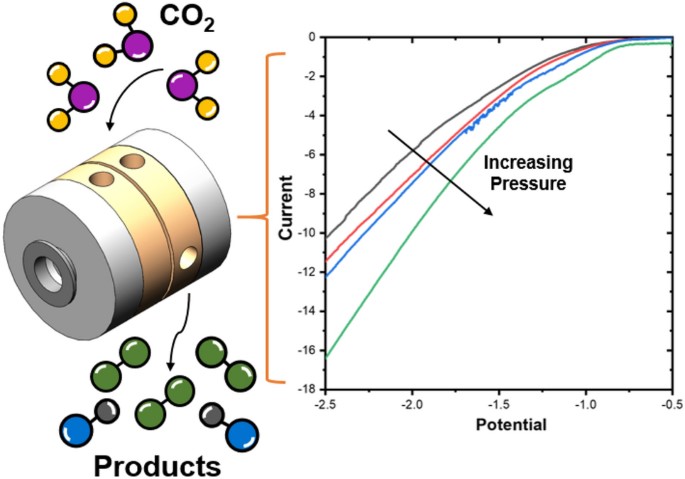

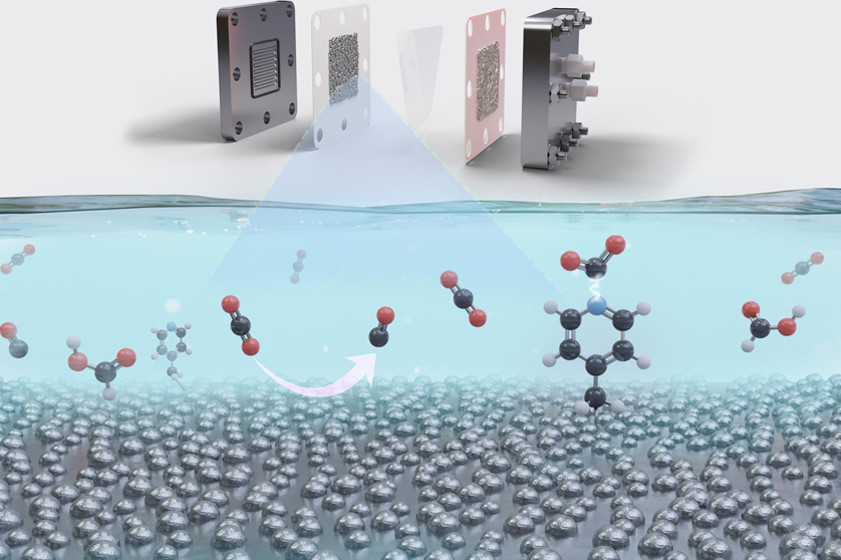

Electrochemical CO2 reduction on a copper foam electrode at elevated pressures

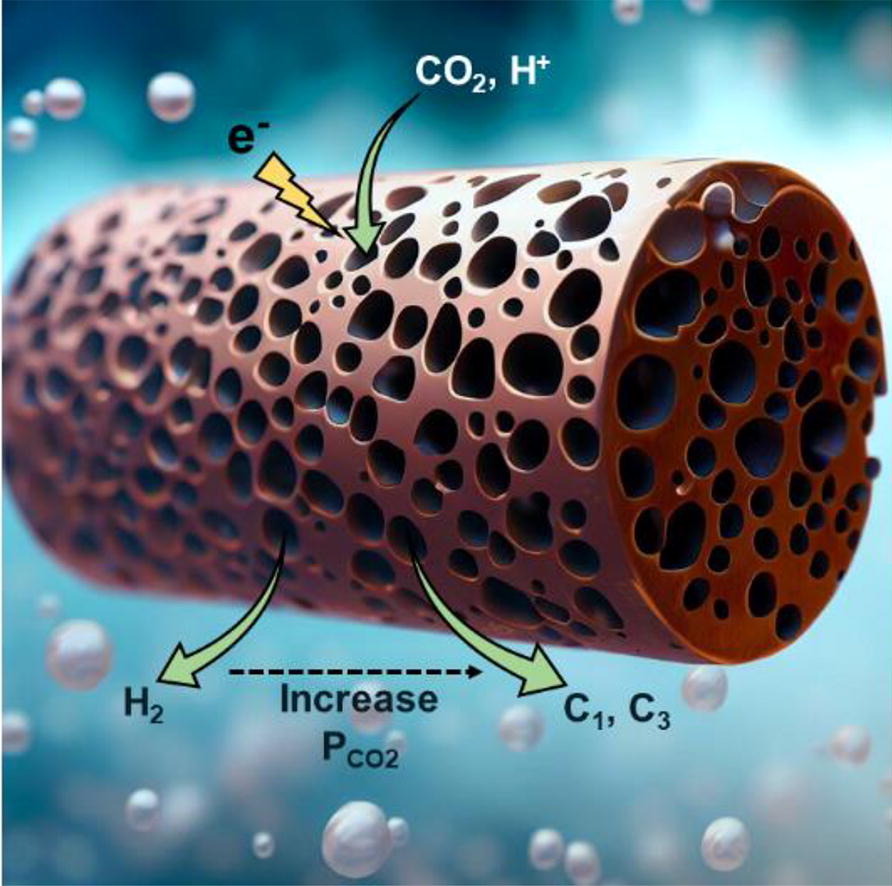

Electrochemical CO2 reduction is a promising way of closing the carbon cycle while synthesizing useful commodity chemicals and fuels. One of the possible routes to scale up the process is CO2 reduction at elevated pressure, as this is a way to increase the concentration of poorly soluble CO2 in aqueous systems. Yet, not many studies focus on this route, owing to the inherent challenges with high-pressure systems, such as leaks, product quantification, and ease of operation. In this study, we use a high-pressure flow cell setup to investigate the impact of CO2 pressure on the electrochemical performance of a copper foam electrode for CO2 reduction within a pressure range of 1 to 25 bar. Our initial findings using a 0.5 M potassium bicarbonate (KHCO3) electrolyte show a consistent improvement in selectivity towards CO2 reduction products, with HCOOH being the dominant product. By conducting a systematic exploration of operating parameters including applied current density, applied CO2 pressure, cation effect, and electrolyte concentration, the selectivity towards formate (HCOOH) is optimized, achieving a remarkable 70 % faradaic efficiency (FE) under moderate conditions of 25 bar in a 0.5 M cesium bicarbonate (CsHCO3) electrolyte. Additionally, we report the synthesis of isopropanol with a FE of 11 % at the 25 bar in 0.5 M KHCO3 which is the highest reported selectivity towards isopropanol on copper using a bicarbonate system.

Nandalal Girichandran, Saeed Saedy, Ruud Kortlever

Earlier publications

-

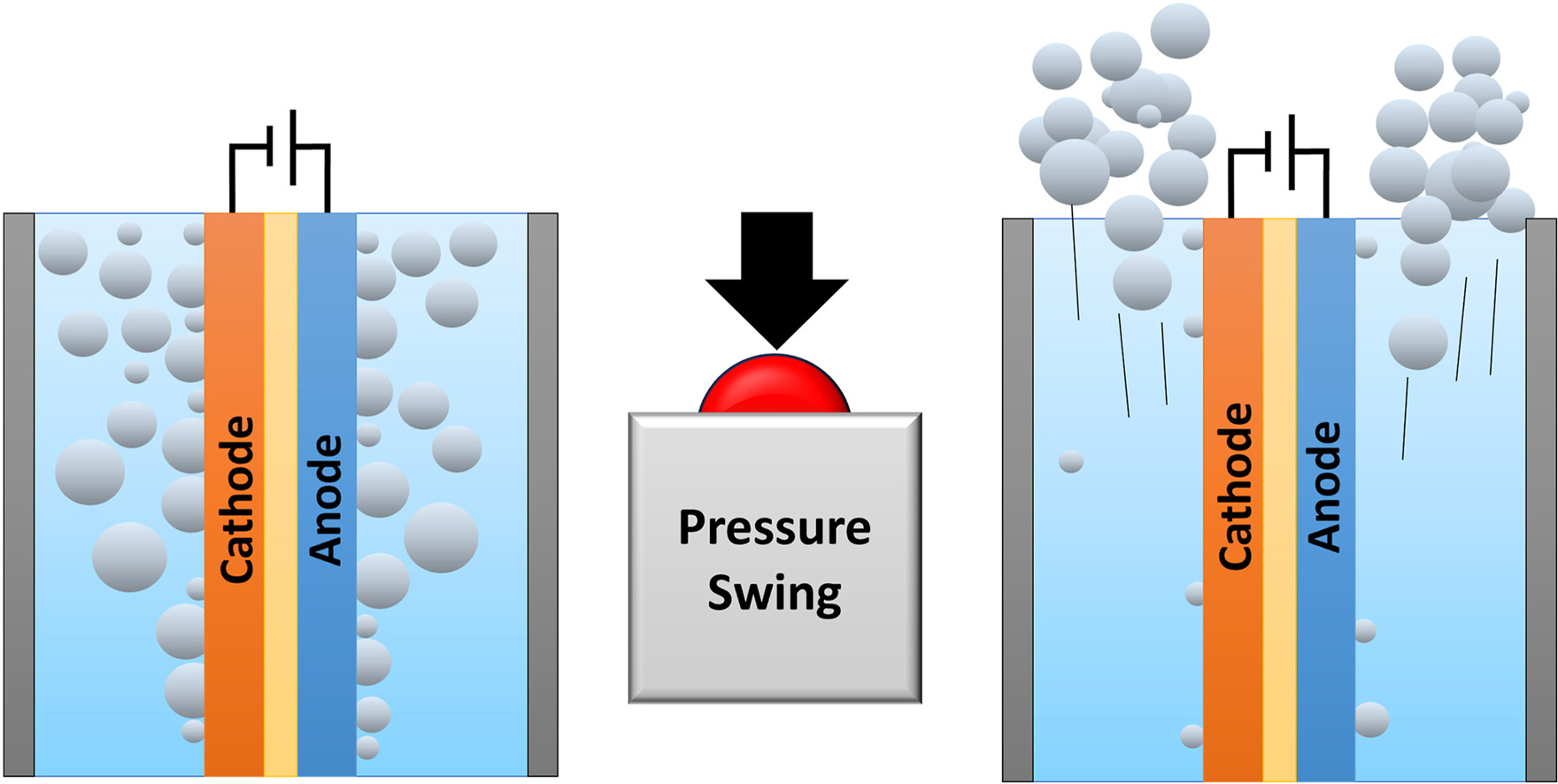

To make green hydrogen more economically attractive, the energy losses in alkaline electrolysis need to be minimized while operating at high current densities (1 A cm−2). At these current densities the ohmic resistance and gas bubbles effects contribute largely to the energy losses. To mitigate the gas bubbles losses, we demonstrate, for the first time, a pressure swing to remove gas bubbles in a zero-gap alkaline water electrolyzer. The pressure swing leverages the ideal gas law to increase the volume of gas in the system periodically, for a short duration (<2 s). This temporal volume increase effectively removes bubbles from the electrolyzer. We show that pressure swing can be used to measure the effect of bubbles on the ohmic resistance (RBubbles). Our results reveal that foam electrodes have a significantly larger RBubbles than perforated plate electrodes (1.8 Ω cm2 vs 0.3 Ω cm2). The time-averaged cell voltage reduces by 170 mV when applying pressure swings to an electrolyzer operating at 200 mA cm−2 in 1 M KOH with foam electrodes. The bubble resistance further depends on the electrolyte conductivity (inversely proportional) and is only moderately affected by operating pressure (25 % lower when increasing pressure amplitude from 1–2 to 1–5 bar). By implementing these findings in a model, we estimate that the pressure swing could reduce the cell voltage by ∼0.1 V for an electrolyzer operating at industrial conditions (6 M KOH, 80 °C, 1 A cm−2) for foam electrodes. For perforated plate electrodes, however, the reduced cell voltage is lower and does not outweigh the additional compression energy.

-

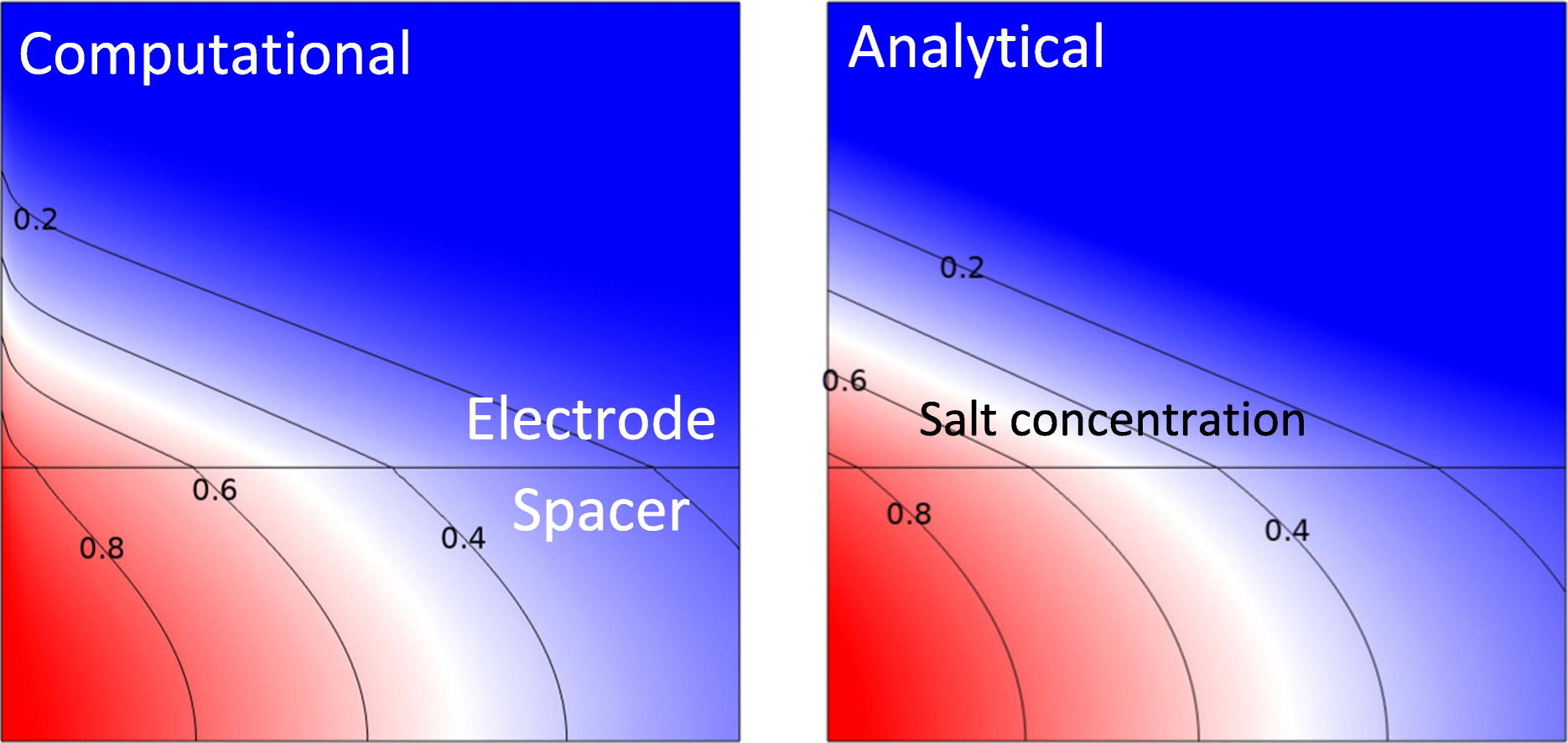

In flow-by capacitive deionization (CDI) brackish water flows between two electrodes that capacitively remove salt. We assume low inlet concentrations so “salt shocks” appear in the electrodes and the process becomes diffusion-limited. For unit charge efficiency, a simplified model is derived consisting of two coupled partial differential equations. We obtain approximations, and exact solutions in terms of the Lambert W function, for the salt concentration as a function of time and space and for the equilibrium charge-voltage relation. These surprisingly simple solutions compare well with the results from comprehensive two-dimensional simulations. Useful analytical expressions are obtained for optimal geometrical and operational parameters that maximize the productivity and minimize the specific energy losses. By making cells much thinner the productivity can be increased an order of magnitude compared to typical values in the literature. The optimal electrode is found to be roughly six times thinner than the spacer. The associated pressure drop is around 0.4 bar per 1 mM of inlet salt concentration, making our recommendations practically feasible only for relatively low concentrations. The obtained model and analytical expressions provide useful guidance to strongly improve the design process.

Haverkort, J. W., Sanderse, B., Padding, J. T., Blake, J. W.

-

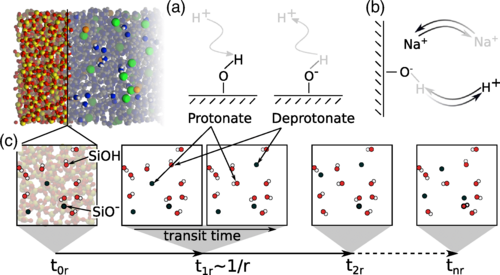

Extending the lifetime of electrocatalytic materials is a major challenge in electrocatalysis. Here, we employ atomic layer deposition (ALD) to coat the surface of carbon black supported platinum nanoparticles (Pt/CB) with an ultra-thin layer of silicon dioxide (SiO2) to prevent deactivation of the catalyst during H2 evolution. Our results show that after an accelerated durability test (ADT) the current density at −0.2 V vs. reversible hydrogen electrode (RHE) of the unprotected Pt/CB catalyst was reduced by 34%. By contrast, after coating the Pt/CB catalyst with 2 SiO2 ALD cycles, the current density at the same potential was reduced by 7% after the ADT procedure, whereas when the Pt/CB sample was coated with 5 SiO2 ALD cycles, the current density was reduced by only 2% after the ADT. Characterization of the Pt particles after electrochemical testing shows that the average particle size of the uncoated Pt/CB catalyst increases by roughly 16% after the ADT, whereas it only increases by 3% for the Pt/CB catalyst coated with 5 cycles of SiO2 ALD. In addition, the coating also strongly reduces the detachment of Pt nanoparticles, as shown by a strong decrease in the Pt concentration in the electrolyte after the ADT. However, 20 cycles of SiO2 ALD coating results in an over-thick coating that has an inhibitory effect on the catalytic activity. In summary, we demonstrate that only a few cycles of SiO2 ALD can strongly improve the stability of Pt catalyst for the hydrogen evolution reaction.

Ming Li, Saeed Saedy, Shilong Fu, Teise Stellema, Ruud Kortlever and J. Ruud van Ommen

-

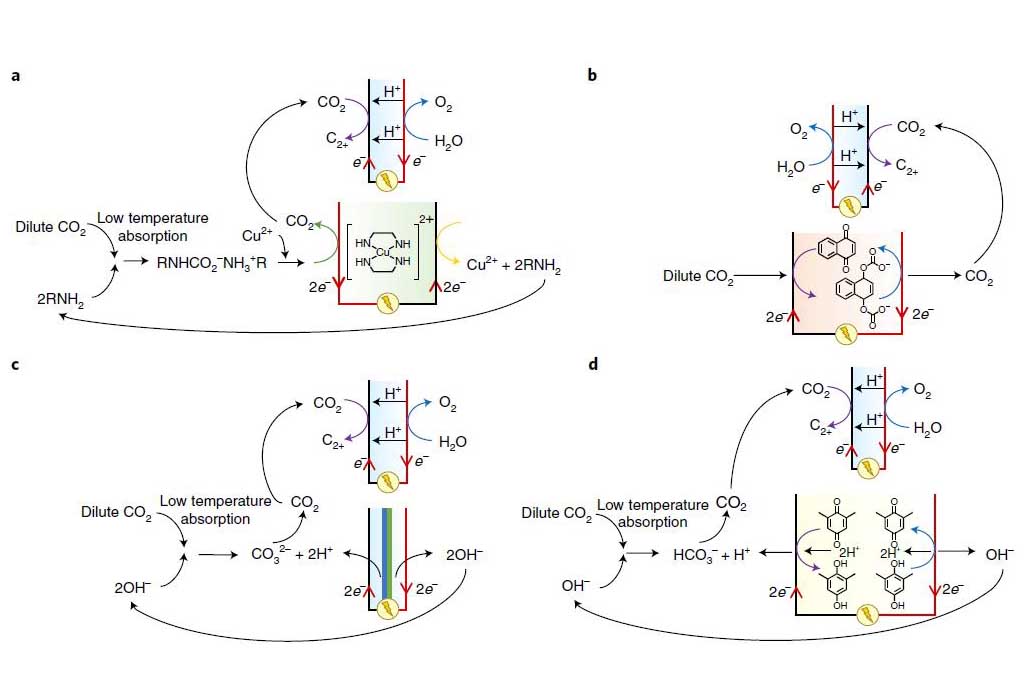

Electrochemical CO2 capture is promising for closing the carbon cycle but needs technological advances. In a recent issue of Nature Energy, a novel chemistry for electrochemical CO2 capture is presented, demonstrating low energy consumption and high purity with virtually no degradation. This finally allows competition with amine-based capture technology.

David A. Vermaas, Ruud Kortlever

-

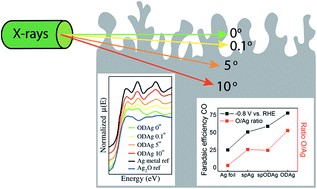

Most research into electrochemical CO2 conversion focusses on improving electrode materials, but neglects the role of the electrolyte. We show the buffer influence on the selectivity of a bimetallic gold–palladium electrode in an effort to elucidate observed inconsistencies between different studies. While hydrocarbons are produced in the phosphate buffer, they remain absent in the bicarbonate buffer, showing that the electrolyte choice plays a crucial role in the selectivity of the electrode.

Daniël van den Berg , Boaz Izelaar , Shilong Fu and Ruud Kortlever

This publication also appeared ont he cover of the Journal Catalysis, Science & Technology

-

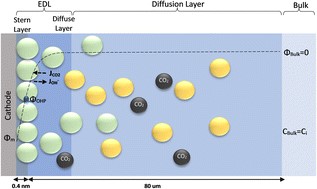

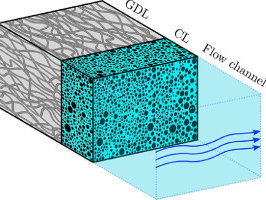

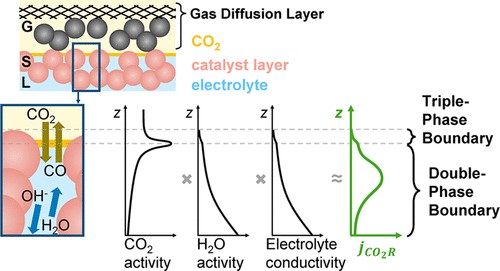

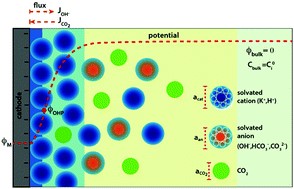

The local conditions inside a gas diffusion electrode (GDE) pore, especially in the electrical double layer (EDL) region, influence the charge transfer reactions and the selectivity of desired CO2ER products. Most GDE computational models ignore the EDL or are limited in their applicability at high potentials. In this work, we present a continuum model to describe the local environment inside a catalytic pore at varying potentials, electrolyte concentrations and pore diameters. The systems studied in this work are based on an Ag catalyst in contact with KHCO3 solution. Our study shows that steric effects dominate the local environment at high cathodic potentials (≪−25 mV vs pzc at the OHP), leading to a radial drop of CO2 concentration. We also observe a drop in pH value within 1 nm of the reaction plane due to electrostatic repulsion and attraction of OH− and H+ ions, respectively. We studied the influence of pore radii (1–10 nm) on electric field and concentrations. Pores with a radius smaller than 5 nm show a higher mean potential, which lowers the mean CO2 concentration. Pores with a favourable local environment can be designed by regulating the ratio between the pore radius and Debye length.

Esaar N. Butt, Johan T. Padding and Remco Hartkamp

-

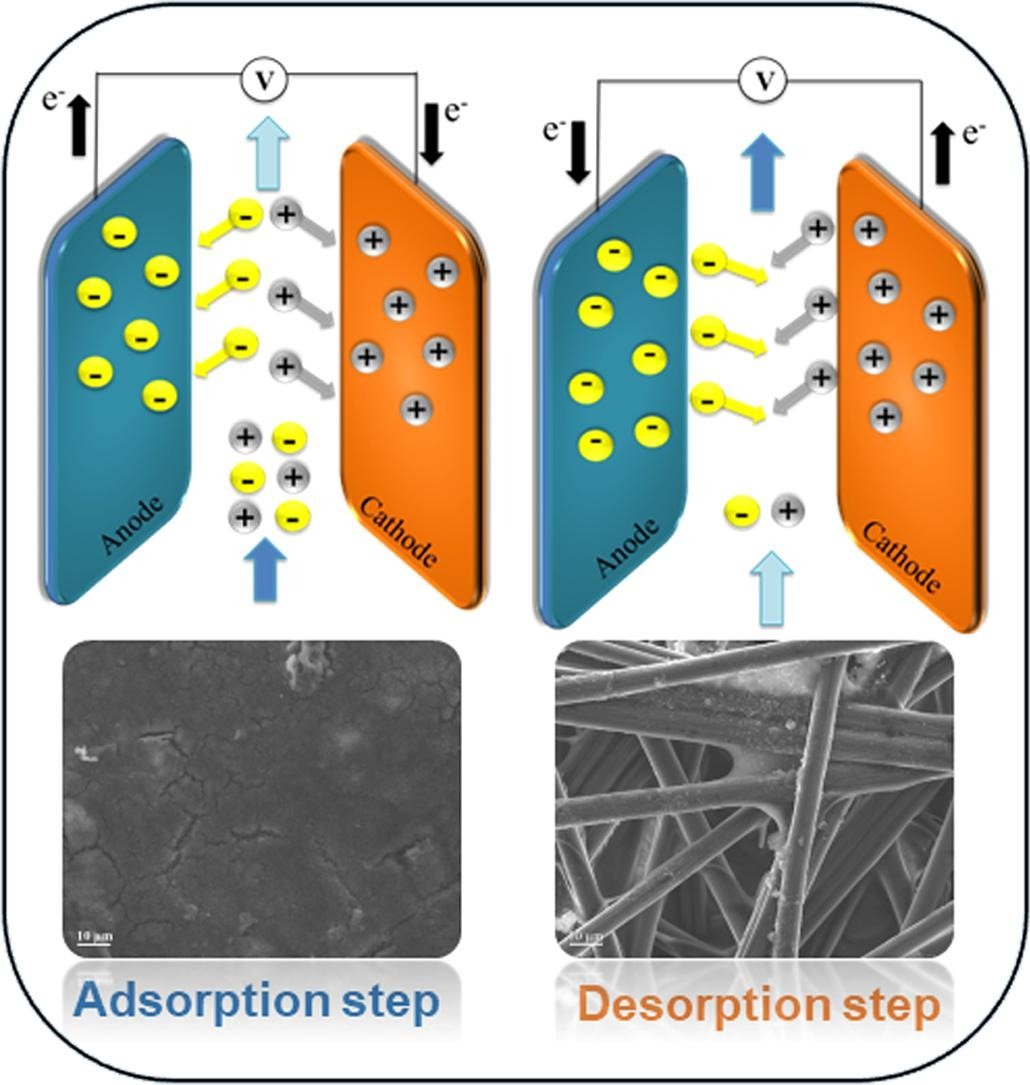

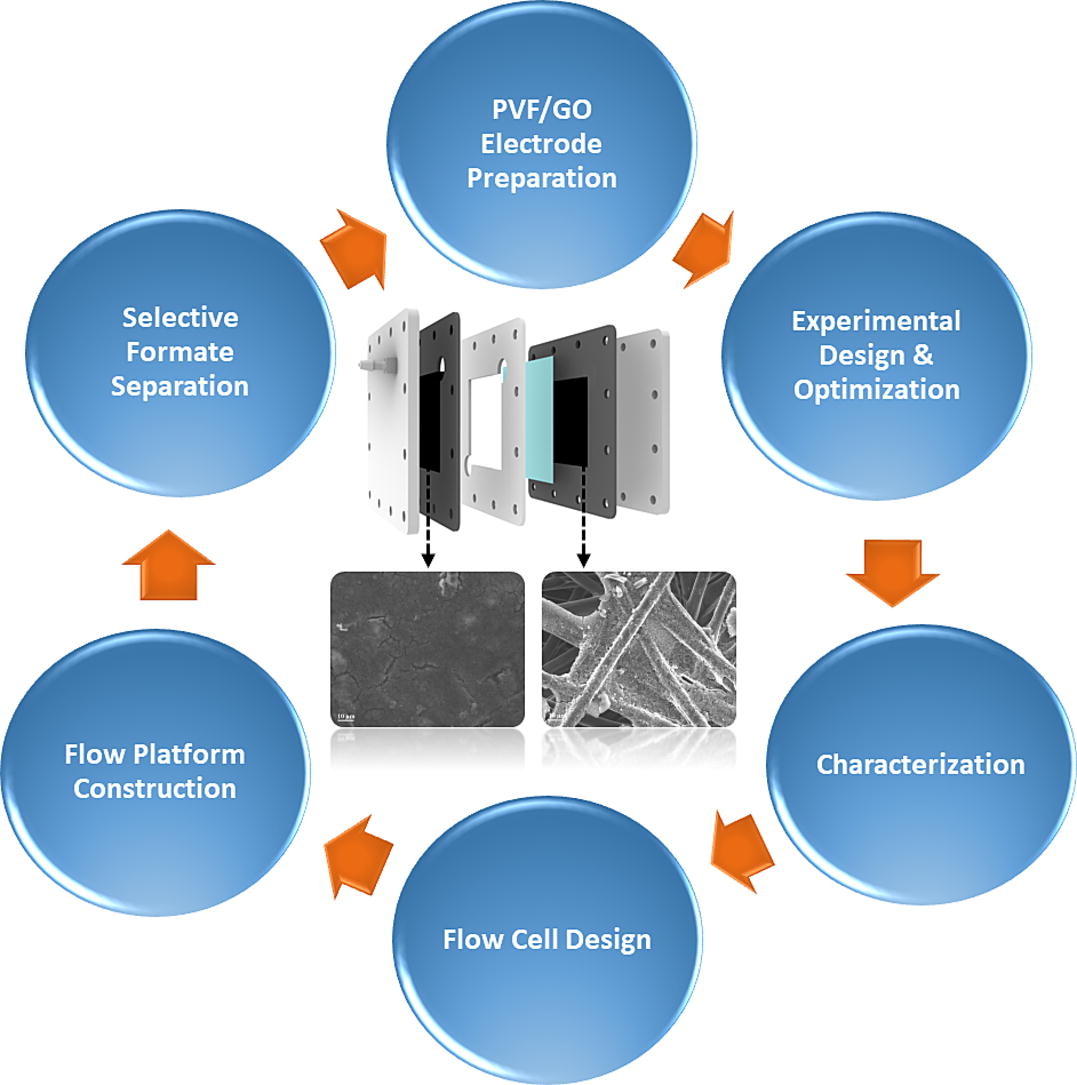

Selective ion separation is a fundamental challenge with applications ranging from the manufacturing of pharmaceuticals & industrial salts to water desalination. In particular, the separation of formate, a primary product of electrochemical carbon dioxide reduction, has attracted attention not only to reduce carbon emissions and energy costs but to provide new routes to value-added chemicals. In the present study, selective formate separation from an aqueous solution is demonstrated using an electrochemical flow cell with symmetric redox-active polyvinyl ferrocene electrodes. An electrosorption system equipped with an electrosorption cell, inline conductivity, and pH sensors was constructed to provide real-time measurements of the formate adsorption performance in continuous flow mode while varying operating conditions such as the flow rate, cell voltage, and electrolyte concentration. These parameters were optimized using a Box–Behnken experimental design to improve the formate adsorption selectivity. The flow cell results showed a selectivity higher than 6.0 toward the removal of formate in an electrolyte containing a 30-fold excess of perchlorate under optimal operation conditions (i.e., 0.5 mL/min flow rate, 1.0 V, and 15 mM electrolyte concentration). The performance of the flow cell was also tested using a solution that contained different liquid CO2 reduction products, and formate separation was achieved. The results suggest that the proper design of the electrochemical cell and efficient operation of the flow platform pave the way for scaling up the technology for selective formate separation.

Sevgi Polat, Ruud Kortlever, Hüseyin Burak Eral

-

Electrochemical carbon dioxide (CO2) reduction is a promising route to convert intermittent renewable energy into fuels and valuable chemical products. Separation of CO2 reduction products by ion-selective electrochemical technology may play a decisive role in the pursuit of commercially viable CO2 reduction processes. Selective separation of formate, one of the main CO2 reduction products, is assessed in the present study in an electrochemical flow cell with symmetric redox-active polyvinyl ferrocene (PVF) functionalized graphene oxide (GO) electrodes. First, experimental parameters such as the PVF/GO ratio, sonication time, and ultrasonic amplitude, were optimized in the electrode preparation process to improve the formate adsorption efficiency on a lab scale (1 × 2 cm electrodes) under static conditions. The electrochemical and morphological characteristics of the electrodes were investigated by cyclic voltammetry and scanning electron microscopy. To demonstrate continuous-flow operation, an electrosorption flow cell (8 × 8 cm) providing inline measurements was constructed. The flow cell results showed selectivity at > 5.5 toward the removal of formate from an electrolyte containing perchlorate at an excess of 30 times the normal value. The performance of the electrosorption cell was also tested using a mixture of methanol, ethanol, formate, and acetaldehyde produced in a CO2 reduction electrolyzer. In this demonstration, formate separation was achieved with a selectivity of > 4.0. The results suggest that the optimized design of the electrochemical cell and operation conditions of the flow platform pave the way for scaling up selective formate separation with PVF/GO electrodes.

Sevgi Polat, Ruud Kortlever, Hüseyin Burak Eral

-

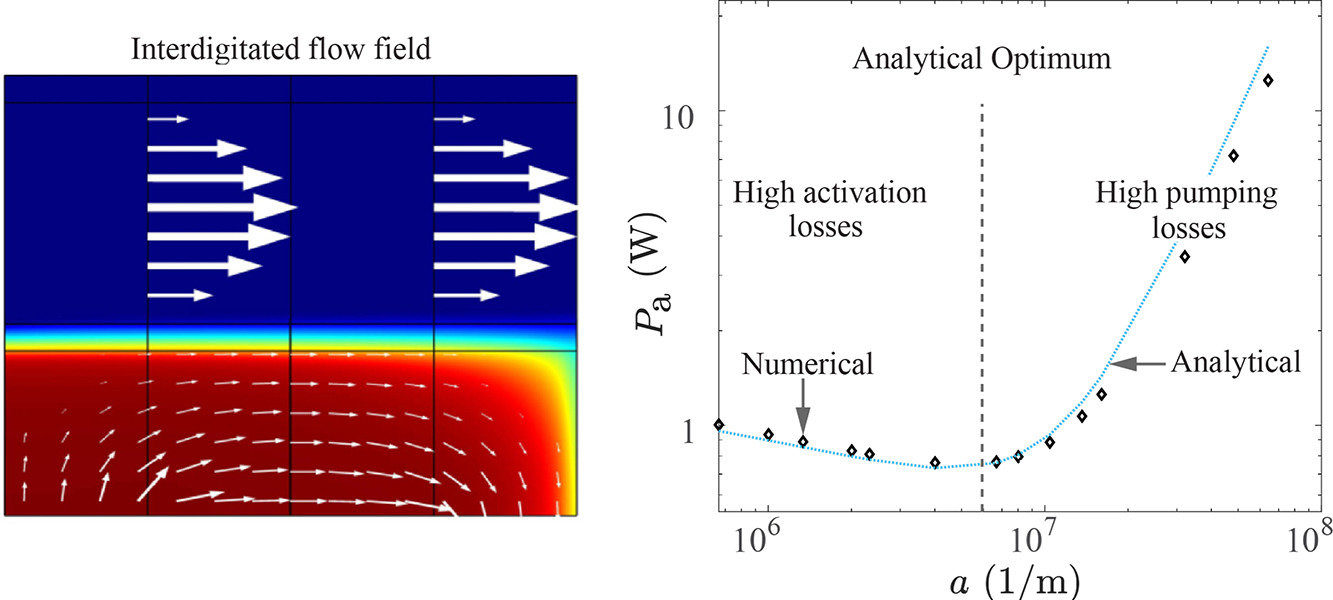

Microfluidic fuel cells, electrolyzers, and redox flow batteries utilize laminar flow channels to provide reactants, remove products and avoid their crossover. These devices often also employ porous flow-through electrodes as they offer a high surface area for the reaction and excellent mass transfer. The geometrical features of these electrodes and flow channels strongly influence energy efficiency. We derive explicit analytical relations for the optimal flow channel width and porous electrode volumetric surface area from the perspective of energy efficiency. These expressions are verified using a two-dimensional tertiary current distribution and porous electrode flow model in COMSOL and are shown to be able to predict optimal parameters in commonly used flow-through and interdigitated flow fields. The obtained analytical models can dramatically shorten modelling time and expedite the industrial design process. The optimal channel width and pore sizes we obtain, in the order of 100 microns and 1 micron respectively, are much smaller than those often used. This shows that there is a significant room for improvement of energy efficiency in flow cells that can sustain the resulting pressure drop.

A. Bhadra, J.W. Haverkort

-

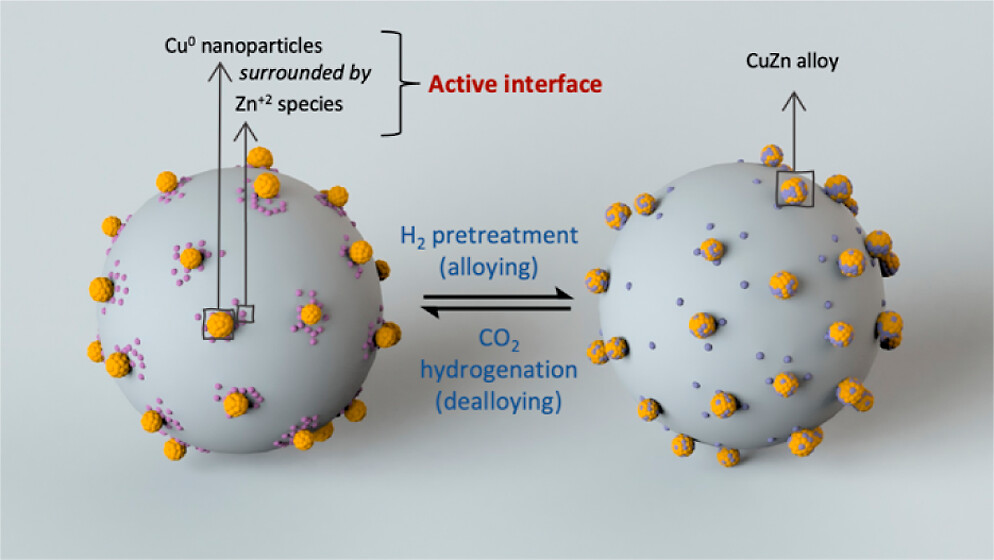

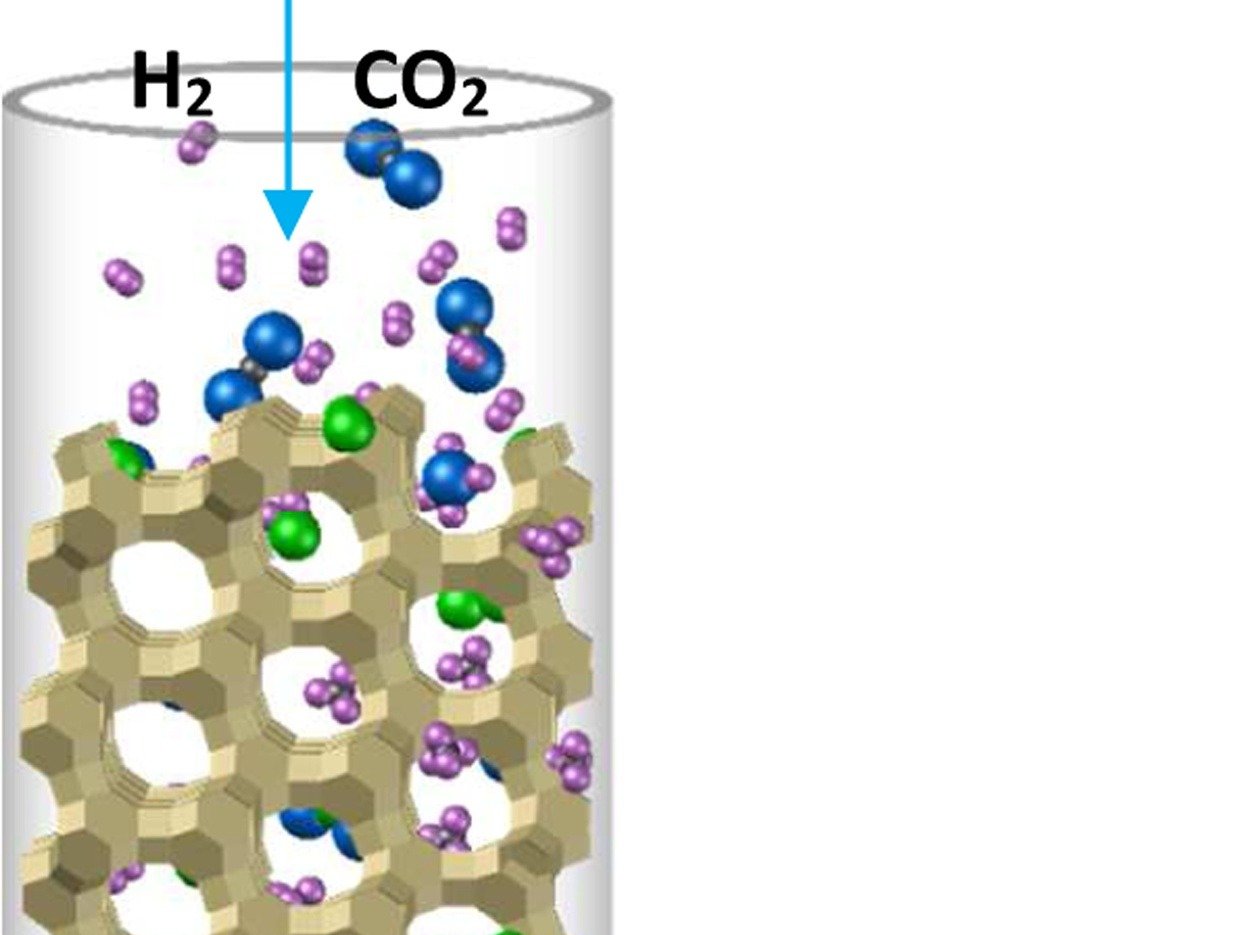

The direct synthesis of methanol via the hydrogenation of CO2, if performed efficiently and selectively, is potentially a powerful technology for CO2 mitigation. Here, we develop an active and selective Cu–Zn/SiO2 catalyst for the hydrogenation of CO2 by introducing copper and zinc onto dehydroxylated silica via surface organometallic chemistry and atomic layer deposition, respectively. At 230 °C and 25 bar, the optimized catalyst shows an intrinsic methanol formation rate of 4.3 g h–1 gCu–1 and selectivity to methanol of 83%, with a space-time yield of 0.073 g h–1 gcat–1 at a contact time of 0.06 s g mL–1. X-ray absorption spectroscopy at the Cu and Zn K-edges and X-ray photoelectron spectroscopy studies reveal that the CuZn alloy displays reactive metal support interactions; that is, it is stable under H2 atmosphere and unstable under conditions of CO2 hydrogenation, indicating that the dealloyed structure contains the sites promoting methanol synthesis. While solid-state nuclear magnetic resonance studies identify methoxy species as the main stable surface adsorbate, transient operando diffuse reflectance infrared Fourier transform spectroscopy indicates that μ-HCOO*(ZnOx) species that form on the Cu–Zn/SiO2 catalyst are hydrogenated to methanol faster than the μ-HCOO*(Cu) species that are found in the Zn-free Cu/SiO2 catalyst, supporting the role of Zn in providing a higher activity in the Cu–Zn system.

Hui Zhou, Scott R. Docherty, Nat Phongprueksathat, Zixuan Chen, Andrey V. Bukhtiyarov, Igor P. Prosvirin, Olga V. Safonova, Atsushi Urakawa, Christophe Copéret, Christoph R. Müller*, and Alexey Fedorov

-

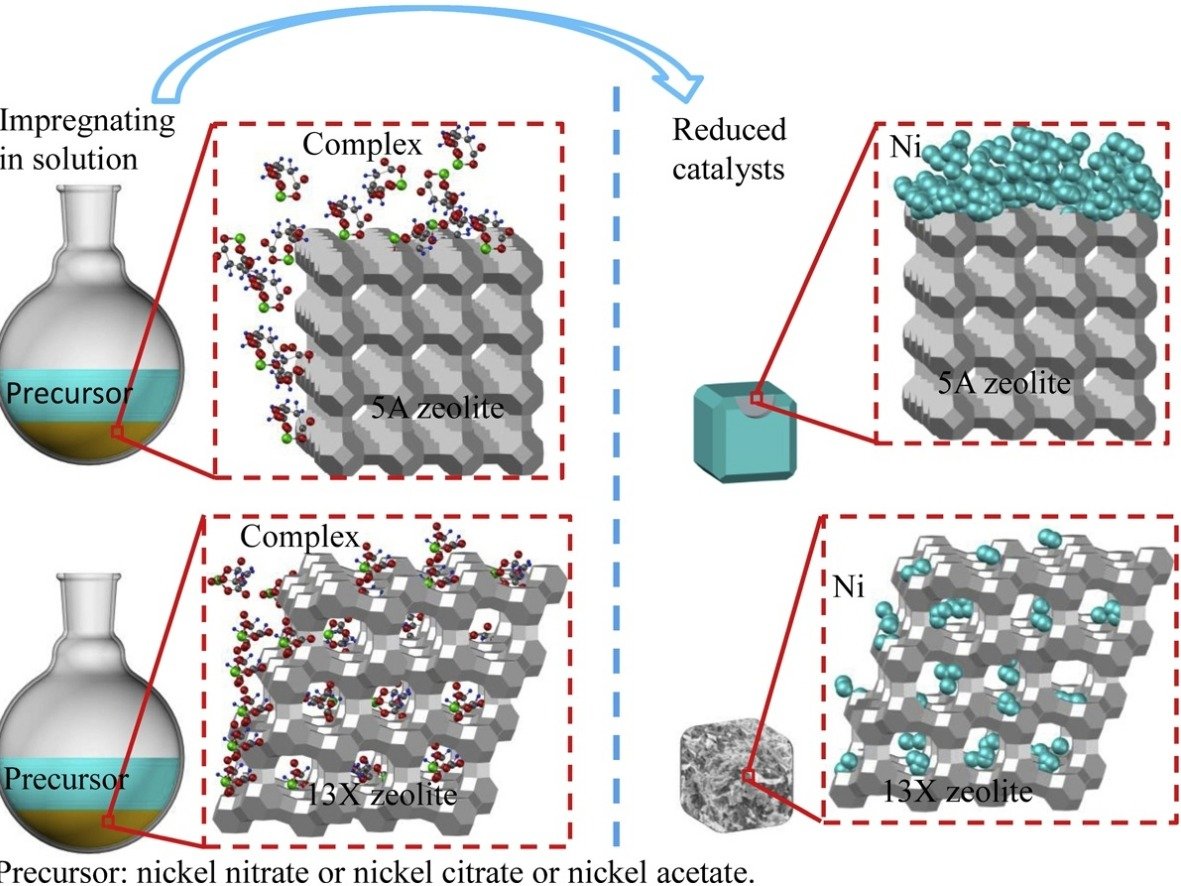

Recently, carbon capture and reduction (CCR) technology has gained interest to directly convert CO2 to value-added products without requiring purification of CO2 and its subsequent transportation. CCR to methanol in one dual function material (DFM) poses mechanistic and kinetic challenges. To counteract this, a process combining Na/Al2O3 as a capture component and Cu/ZnO/Al2O3 (CZA) as methanol synthesis catalyst was developed to allow CCR to methanol. With a 5 vol% CO2 flow for capture and subsequent H2 stream combined with a temperature swing, a methanol selectivity of 26 % was achieved at 9 bar. Further investigation found that Na/Al2O3 significantly increased methanol yield, while a stacked configuration of Na/Al2O3 followed by CZA significantly outperformed a mixed configuration of the two catalysts. With further investigation of operation at higher pressure and surface mechanism, an effective CCR to methanol process using two affordable yet readily available catalysts can be realized.

Luca C. Wirner, Fumihiko Kosaka, Tomone Sasayama, Yanyong Liu, Atsushi Urakawa, Koji Kuramoto

-

Reaching our climate goals will require urgent advancements in the development of fossil-free technologies. Solid-oxide electrolysis (SOE) at high-temperature is a promising candidate for combining CO₂ utilization and renewable electricity use. Explorative techno-economic analyses are being performed to understand the full plant design requirements for integrated SOE systems. However, there is still a lack of understanding of the potential impact that the pre-treatment of CO₂ will have on the overall design and economics of a SOE-based system. To address this knowledge gap, as a first step, the process model of the pre-treatment units needed to purify CO₂ from a bioethanol plant is developed in Aspen Plus in the current work. Based on the preliminary results of this paper, the equipment costs mainly stem from the units related to the removal of sulfur (~65%) and alcohols (~32%). The energy costs are almost entirely related to the cryogenic distillation step required for the removal of non-condensable gases (~96%).

Josephine Vos, Andrea Ramirez, Mar Pérez-Fortes

-

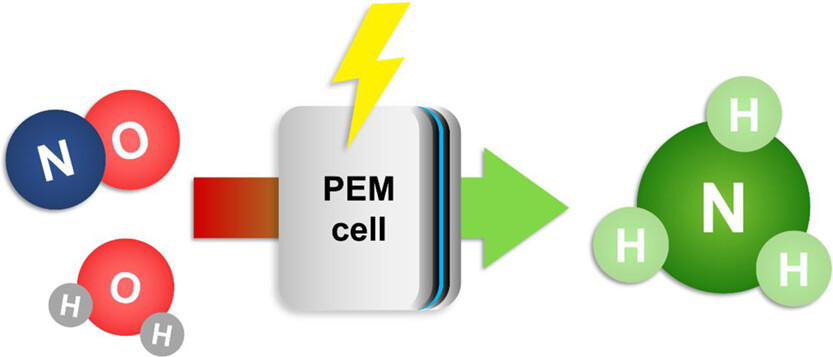

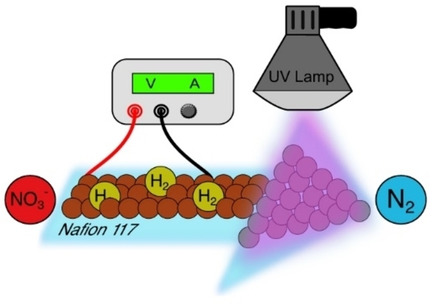

The continuous electrochemical NO reduction to ammonia in a PEM cell was investigated in this work. We used a ruthenium-based catalyst at the cathode and an iridium oxide catalyst at the anode. The highest ammonia faradaic efficiency was observed at 1.9 V cell voltage. Adjusting the NO flow allowed to achieve 97% NO conversion and 93% ammonia faradaic efficiency for a 5.2% NO/He feed. The ammonia yield was 0.51 mmol cm–2 h–1, among the highest reported to date with the advantage of continuous operation. Experiments with a low NO concentration feed of 983 ppm showed 98% conversion at 0 V vs pseudo-RHE. Achieving this performance under such mild conditions indicates the great potential of the PEM cells for NOx abatement applications and the production of valuable NH3.

Sorin Bunea, Manoj Coppens, and Atsushi Urakawa

-

Due to the heavy dependence on fossil-fuels as raw materials, the defossilization of feedstocks in the petrochemical industry represents a challenge. A large number of possible process routes that use alternative carbon sources (ACS) like CO2, biomass, and waste are being developed for the feedstock replacement. For instance, to produce ethylene, more than 40 ACS process routes were identified. These multiple options make the selection of the promising process route a complex task. By replacing feedstocks, a process can change significantly and the impacts related to these changes in a highly interconnected industrial cluster can create cascading effects due to system interdependencies. This work aims to understand the cascading impacts in carbon flows and prices of implementing an ACS production process in an ethylene cluster. The results show that PVC will be the highest impacted and defossilizing one value-chain can have cascading effect on other value-chains as observed for PET.

James Tonny Manalal, Mar Pérez-Fortes, Paola Ibarra Gonzalez, Andrea Ramirez Ramirez

-

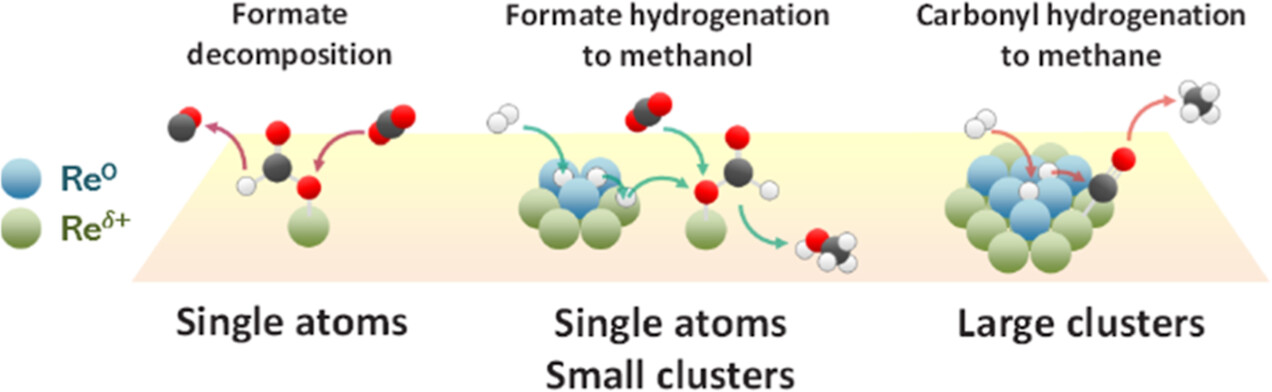

Low temperature and high pressure are thermodynamically more favorable conditions to achieve high conversion and high methanol selectivity in CO2 hydrogenation. However, low-temperature activity is generally very poor due to the sluggish kinetics, and thus, designing highly selective catalysts active below 200 °C is a great challenge in CO2-to-methanol conversion. Recently, Re/TiO2 has been reported as a promising catalyst. We show that Re/TiO2 is indeed more active in continuous and high-pressure (56 and 331 bar) operations at 125–200 °C compared to an industrial Cu/ZnO/Al2O3 catalyst, which suffers from the formation of methyl formate and its decomposition to carbon monoxide. At lower temperatures, precise understanding and control over the active surface intermediates are crucial to boosting conversion kinetics. This work aims at elucidating the nature of active sites and active species by means of in situ/operando X-ray absorption spectroscopy, Raman spectroscopy, ambient-pressure X-ray photoelectron spectroscopy (AP-XPS), and diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS). Transient operando DRIFTS studies uncover the activation of CO2 to form active formate intermediates leading to methanol formation and also active rhenium carbonyl intermediates leading to methane over cationic Re single atoms characterized by rhenium tricarbonyl complexes. The transient techniques enable us to differentiate the active species from the spectator one on TiO2 support, such as less reactive formate originating from spillover and methoxy from methanol adsorption. The AP-XPS supports the fact that metallic Re species act as H2 activators, leading to H-spillover and importantly to hydrogenation of the active formate intermediate present over cationic Re species. The origin of the unique reactivity of Re/TiO2 was suggested as the coexistence of cationic highly dispersed Re including single atoms, driving the formation of monodentate formate, and metallic Re clusters in the vicinity, activating the hydrogenation of the formate to methanol.

Nat Phongprueksathat, Kah Wei Ting, Shinya Mine, Yuan Jing, Ryo Toyoshima, Hiroshi Kondoh, Ken-ichi Shimizu, Takashi Toyao, and Atsushi Urakawa

-

Electrochemical reduction of CO2 (CO2ER) is an emerging technology with the potential to limit the use of fossil-based feedstocks in the petrochemical industry by converting CO2 and renewable electricity into useful products such as syngas. Its successful deployment will depend not only on the technology's performance but also on its integration into the supply chain. In this work, a facility location model is used to gain insights regarding the capacity of CO2ER plants that produce syngas and the implications for the central/decentral placement of these CO2-based syngas plants. Different optimal configurations are examined in the model by changing the syngas transport costs. In this exploratory case, the results indicate that centralization is only an option when the syngas and CO2 transport costs are similar. When syngas transport is more expensive, decentralizing CO2-based syngas plants in the supply chain appears more feasible.

Thijmen Wiltink, Stijn Yska, Andrea Ramirez, Mar Pérez-Fortes

-

Using alternative carbon sources (ACS) to produce downstream derivatives (DDs) is a promising option for defossilising the chemical industry. However, the potential consequences of using ACS in interconnected petrochemical clusters are generally overlooked. This paper aims to develop a methodological approach for systematically analysing defossilisation impacts at the value chain level. For this, a single value chain for producing methyl-tert-butyl-ether (MTBE) was used as a case study. The individual components of the value chain were modelled in Aspen Plus v12. Both ACS- and fossil-based value chains were compared in terms of (i) changes in the structure of the value chain and (ii) the magnitude of the impacts. The results show that the defossilisation of a single value chain causes additional impacts at the cluster level.

Inna Stepchuk, Mar Pérez-Fortes, Andrea Ramírez Ramírez

-

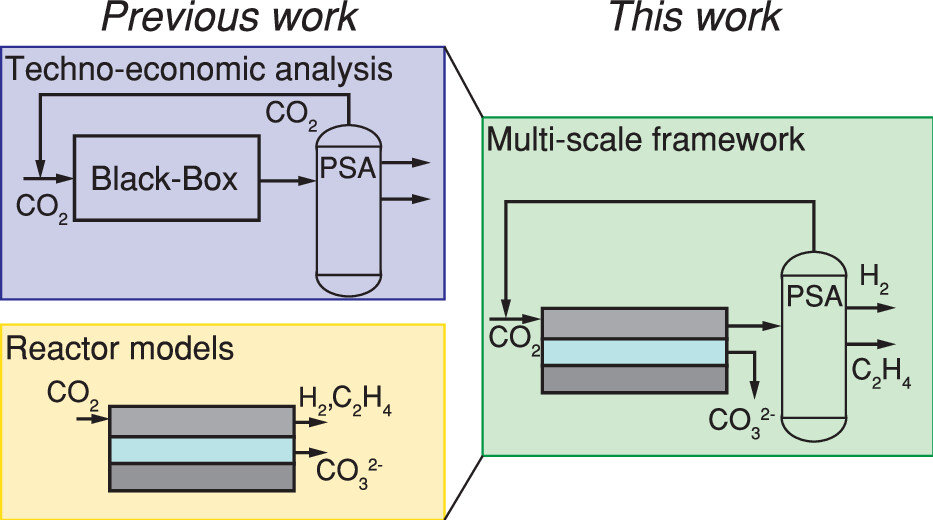

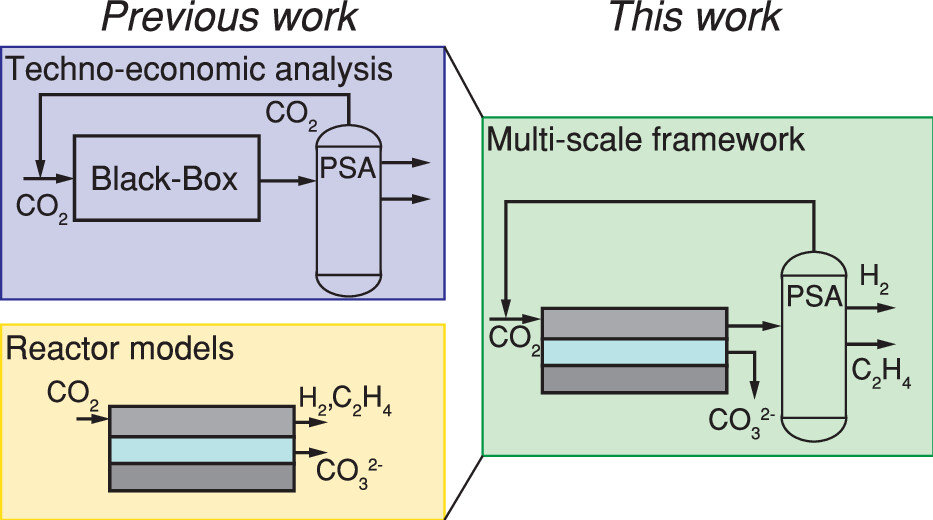

The production of base chemicals by electrochemical conversion of captured CO2 has the potential to close the carbon cycle, thereby contributing to a future energy transition. With the feasibility of low-temperature electrochemical CO2 conversion demonstrated at lab scale, research is shifting toward optimizing electrolyser design and operation for industrial applications, with target values based on techno-economic analysis. However, current techno-economic analyses often neglect experimentally reported interdependencies of key performance variables such as the current density, the faradaic efficiency, and the conversion. Aiming to understand the impact of these interdependencies on the economic outlook, we develop a model capturing mass transfer effects over the channel length for an alkaline, membrane electrolyser. Coupling the channel scale with the higher level process scale and embedding this multiscale model in an economic framework allows us to analyze the economic trade-off between the performance variables. Our analysis shows that the derived target values for the performance variables strongly depend on the interdependencies described in the channel scale model. Our analysis also suggests that economically optimal current densities can be as low as half of the previously reported benchmarks. More generally, our work highlights the need to move toward multiscale models, especially in the field of CO2 electrolysis, to effectively elucidate current bottlenecks in the quest toward economically compelling system designs.

Isabell Bagemihl, Lucas Cammann, Mar Pérez-Fortes, Volkert van Steijn, J. Ruud van Ommen

-

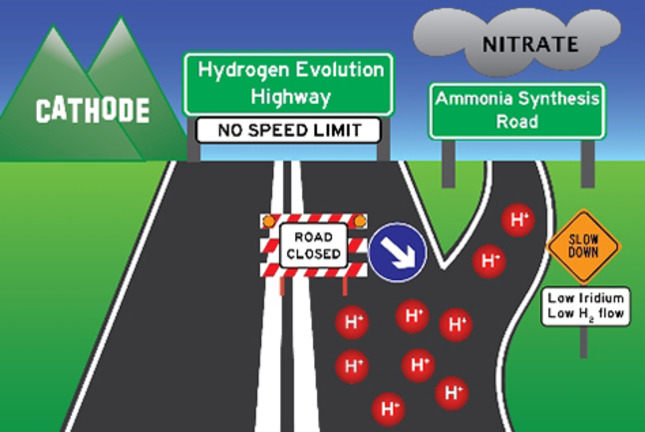

Direct electroreduction of nitric oxide offers a promising avenue to produce valuable chemicals, such as ammonia, which is an essential chemical to produce fertilizers. Direct ammonia synthesis from NO in a polymer electrolyte membrane (PEM) electrolyzer is advantageous for its continuous operation and excellent mass transport characteristics. However, at a high current density, the faradaic efficiency of NO electroreduction reaction is limited by the competing hydrogen evolution reaction (HER). Herein, we report a CO-mediated selective poisoning strategy to enhance the faradaic efficiency (FE) towards ammonia by suppressing the HER. In the presence of only NO at the cathode, Pt/C and Pd/C catalysts showed a lower FE towards NH3 than to H2 due to the dominating HER. Cu/C catalyst showed a 78 % FE towards NH3 at 2.0 V due to the stronger binding affinity to NO* compared to H*. By co-feeding CO, the FE of Cu/C catalyst towards NH3 was improved by 12 %. More strikingly, for Pd/C, the FE towards NH3 was enhanced by 95 % with CO co-feeding, by effectively suppressing HER. This is attributed to the change of the favorable surface coverage resulting from the selective and competitive binding of CO* to H* binding sites, thereby improving NH3 selectivity.

Min Li, Jarco Verkuil, Dr. Sorin Bunea, Dr. Ruud Kortlever, Prof. Dr. Atsushi Urakawa

-

This review provides a comprehensive overview of the dynamics of low-temperature water electrolyzers and their influence on coupling the three major technologies, alkaline, Proton Exchange Membrane (PEM) and, Anion Exchange Membrane (AEM) with photovoltaic (PV) systems. Hydrogen technology is experiencing considerable interest as a way to accelerate the energy transition. With no associated CO2 emissions and fast response, water electrolyzers are an attractive option for producing green hydrogen on an industrial scale. This can be seen by the ambitious goals and large-scale projects being announced for hydrogen, especially with solar energy dedicated entirely to drive the process. The electrical response of water electrolyzers is extremely fast, making the slower variables, such as temperature and pressure, the limiting factors for variable operation typically associated with PV-powered electrolysis systems. The practical solar-to-hydrogen efficiency of these systems is in the range of 10% even with a very high coupling factor exceeding 99% for directly coupled systems. The solar-to-hydrogen efficiency can be boosted with a battery, potentially sacrificing the cost. The intermittency of solar irradiance, rather than its variability is the biggest challenge for PV-hydrogen systems regarding operation and degradation.

V.A. Martinez Lopez, H. Ziar, J.W. Haverkort, M. Zeman, O. Isabella

-

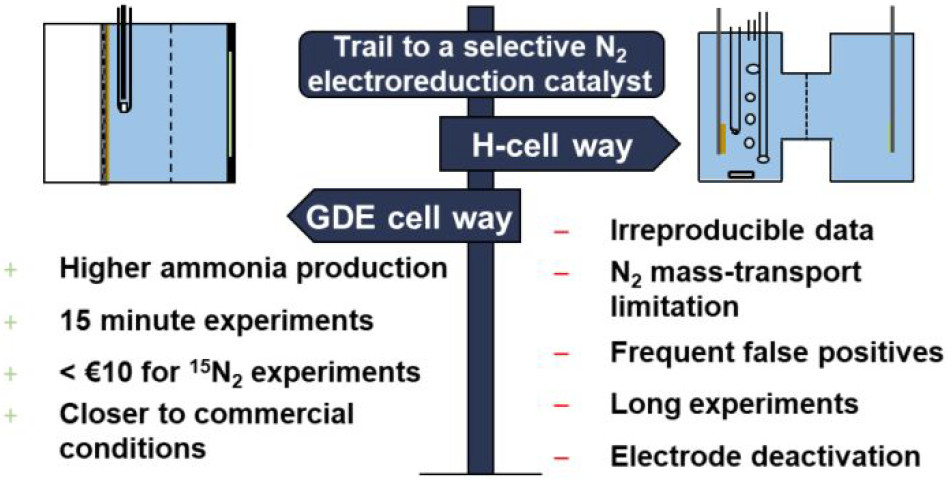

Ammonia (NH3) ranks among the largest bulk chemical products in the world, with an annual production of 178 million tons and an estimated annual market growth of 3–5% to meet the global demand for fertilizer in the agricultural sector due to an increasing world population. (1,2) The majority of NH3 is produced by the Haber–Bosch process, wherein elevated temperatures (300–500 °C) and pressures (200–300 bar) are required. (3) In addition, the current process has a major environmental impact (∼1% of the global greenhouse emissions), mostly due to the production of hydrogen by steam-methane reforming. (4) To meet the net-zero emissions goal by 2050, as established in the latest IPCC report, (5) ammonia must be produced via a sustainable pathway. (6) Direct electrocatalytic synthesis of ammonia from dinitrogen and water at mild conditions could potentially offer a carbon-free alternative, resilient to intermittent renewable energy generation. (7)

Boaz Izelaar, Davide Ripepi, Dylan D. van Noordenne, Peter Jungbacker, Ruud Kortlever*, and Fokko M. Mulder

-

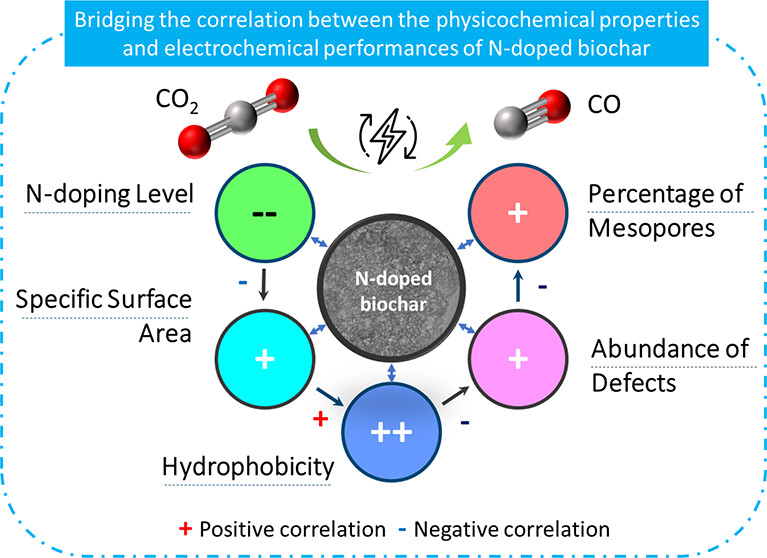

Nitrogen-doped (N-doped) carbon catalysts have been widely studied for electrochemical CO2 reduction to CO. However, the correlation between the physicochemical properties of N-doped carbon catalysts and their electrocatalytic performance for the CO2RR is still unclear. Herein, a series of N-doped biochar catalysts with different physicochemical properties were synthesized by tuning the carbonization temperature and N-doping level and used for the CO2RR to analyze the structure–performance relationship. The prepared catalysts exhibited massive differences in maximum faradaic efficiency to CO from 26.8 to 94.9% at around −0.8 to −0.9 V vs RHE. In addition, we find that simply increasing the specific surface area and N-doping level of the catalysts does not effectively improve the catalytic performance for the CO2RR. A multivariate correlation analysis reveals a negative correlation between the N-doping content and the electrochemical performance. The porous structural properties exhibit a positive correlation to the FECO but almost no correlation to jCO. Interestingly, improving the degree of graphitization, surface hydrophobicity, the abundance of defects, and optimizing the porosity of the N-doped biochar catalyst can efficiently enhance the catalytic performance for the CO2RR. We conclude that comprehensively analyzing the synergistic effect of various properties of N-doped biochar is critical to reveal structure–activity relationships.

Shilong Fu, Ming Li, Wiebren de Jong, and Ruud Kortlever

-

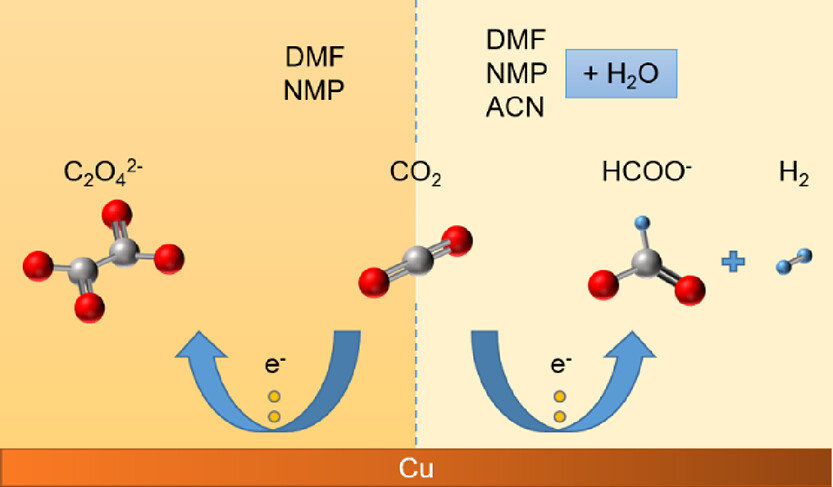

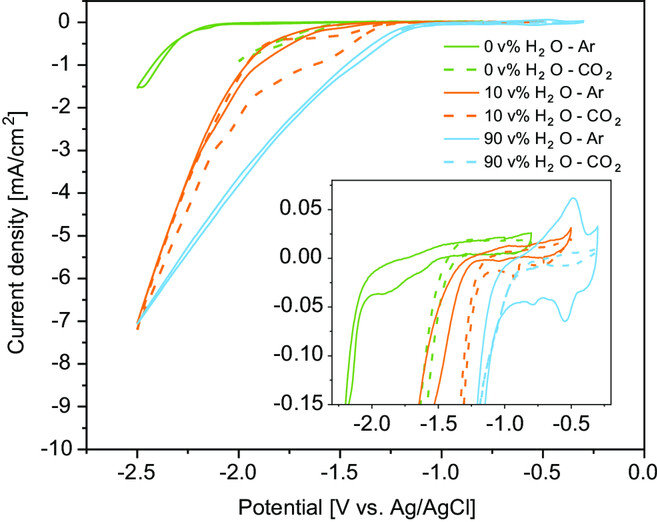

Aqueous electrolytes used in CO2 electroreduction typically have a CO2 solubility of around 34 mM under ambient conditions, contributing to mass transfer limitations in the system. Non-aqueous electrolytes exhibit higher CO2 solubility (by 5–8-fold) and also provide possibilities to suppress the undesired hydrogen evolution reaction (HER). On the other hand, a proton donor is needed to produce many of the products commonly obtained with aqueous electrolytes. This work investigates the electrochemical CO2 reduction performance of copper in non-aqueous electrolytes based on dimethylformamide (DMF), n-methyl-2-pyrrolidone (NMP), and acetonitrile (ACN). The main objective is to analyze whether non-aqueous electrolytes are a viable alternative to aqueous electrolytes for hydrocarbon production. Additionally, the effects of aqueous/non-aqueous anolytes, membrane, and the selection of a potential window on the electrochemical CO2 reduction performance are addressed in this study. Experiments with pure DMF and NMP mainly produced oxalate with a faradaic efficiency (FE) reaching >80%; however, pure ACN mainly produced hydrogen and formate due to the presence of more residual water in the system. Addition of 5% (v/v) water to the non-aqueous electrolytes resulted in increased HER and formate production with negligible hydrocarbon production. Hence, we conclude that aqueous electrolytes remain a better choice for the production of hydrocarbons and alcohols on a copper electrode, while organic electrolytes based on DMF and NMP can be used to obtain a high selectivity toward oxalate and formate.

Asvin Sajeev Kumar, Marilia Pupo, Kostadin V. Petrov, Mahinder Ramdin, J. Ruud van Ommen, Wiebren de Jong, and Ruud Kortlever

-

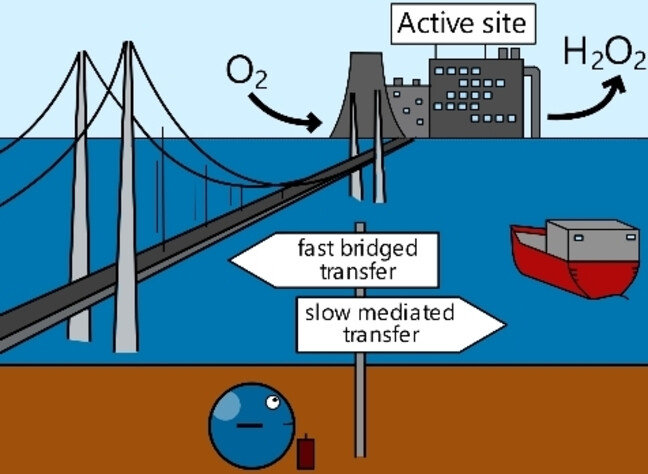

Immobilizing molecular catalysts on electrodes is vital for electrochemical applications. However, creating robust electrode-catalyst interactions while maintaining good catalytic performance and rapid electron transfer is challenging. Here, without introducing any foreign elements, we show a bottom-up synthetic approach of constructing the conjugated C−C bond between the commercial Vulcan carbon electrode and an organometallic catalyst. Characterization results from FTIR, XPS, aberration-corrected TEM and EPR confirmed the successful and uniform heterogenization of the complex. The synthesized Vulcan-LN4−Co catalyst is highly active and selective in the oxygen reduction reaction in neutral media, showing an 80 % hydrogen peroxide selectivity and a 0.72 V (vs. RHE) onset potential which significantly outperformed the homogenous counterpart. Based on single-crystal XRD and NMR data, we built a model for density functional theory calculations which showed a nearly optimal binding energy for the *OOH intermediate. Our results show that the direct conjugated C−C bonding is an effective approach for heterogenizing molecular catalysts on carbon, opening new opportunities for employing molecular catalysts in electrochemical applications.

Dr. Jasper Biemolt, Eva J. Meeus, Felix J. de Zwart, Jeen de Graaf, Petrus C. M. Laan, Prof. Dr. Bas de Bruin, Dr. Thomas Burdyny, Prof. Dr. Gadi Rothenberg, Prof. Dr. Ning Yan

-

The production of base chemicals by electrochemical conversion of captured CO2 has the potential to close the carbon cycle, thereby contributing to a future energy transition. With the feasibility of low-temperature electrochemical CO2 conversion demonstrated at lab scale, research is shifting toward optimizing electrolyser design and operation for industrial applications, with target values based on techno-economic analysis. However, current techno-economic analyses often neglect experimentally reported interdependencies of key performance variables such as the current density, the faradaic efficiency, and the conversion. Aiming to understand the impact of these interdependencies on the economic outlook, we develop a model capturing mass transfer effects over the channel length for an alkaline, membrane electrolyser. Coupling the channel scale with the higher level process scale and embedding this multiscale model in an economic framework allows us to analyze the economic trade-off between the performance variables. Our analysis shows that the derived target values for the performance variables strongly depend on the interdependencies described in the channel scale model. Our analysis also suggests that economically optimal current densities can be as low as half of the previously reported benchmarks. More generally, our work highlights the need to move toward multiscale models, especially in the field of CO2 electrolysis, to effectively elucidate current bottlenecks in the quest toward economically compelling system designs.

Isabell Bagemihl, Lucas Cammann, Mar Pérez-Fortes, Volkert van Steijn, and J. Ruud van Ommen

-

Yannai Kashtan and his colleagues propose that universities should sever research links with fossil-fuel companies (Nature 612, 404; 2022). We argue that collaboration in some areas is essential to ensure a timely transition to clean energy, given the substantial funding needed to quickly develop and scale up green technologies.

A transition to low-emitting processes will be slow and expensive for some industries. In the chemical industry, for instance, around 200 million tonnes of ethylene are produced annually. A newly developed sustainable process that produces 25,000 tonnes of ethylene per year would need 30 years to reach this output at a compound annual growth rate of 35%. Only companies that are already embedded into supply chains and the global energy infrastructure can reorient such mega-chemical production routes in a reasonable timeframe.

Universities need immense amounts of funding to train researchers, advance new technologies and develop prototypes. And industry understands the challenges that need to be addressed for successful upscaling. Working together will therefore benefit society, provided that the collaboration promotes a zero-emission energy system.

Thomas Burdyny and Bernard Dam

-

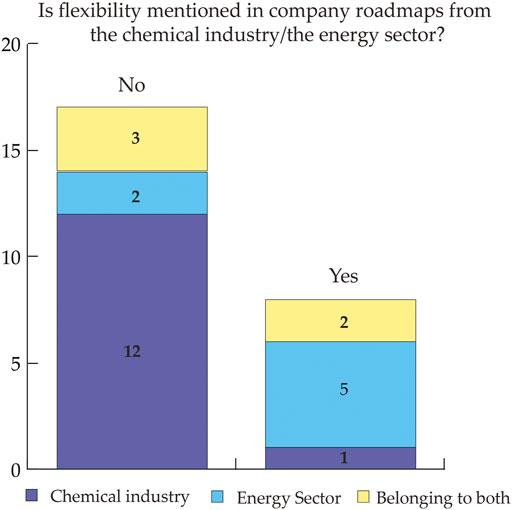

Electrification of processes and utilities is considered a promising option towards the reduction of greenhouse gas emissions from the chemical industry. Therefore, electricity demand is expected to increase steeply. Since the sources of future low-carbon electricity are variable in nature, there is a need for strategies to match availability and demand. Literature identified the flexibility of chemical processes as one promising strategy to address variability. This study aims to provide insights into how stakeholders from the power sector and the chemical industry consider flexibility in chemical processes and to identify key benefits and bottlenecks. For this article, we combined a review of peer-reviewed and grey literature with stakeholder interviews to map and describe the state of the art of flexible chemicals production, and to identify requirements for further research. The main drivers to investigate the flexibility potential are first, the contribution to energy system reliability, and second, potential cost savings for the industry. Main limitations are considered to be first, the uncertain economic performance of flexible processes due to investment costs, reduced production and uncertain revenues from flexible operation, and second, the complexity of the implementation of flexibility.

Svenja Bielefeld, Miloš Cvetković, Andrea Ramírez

-

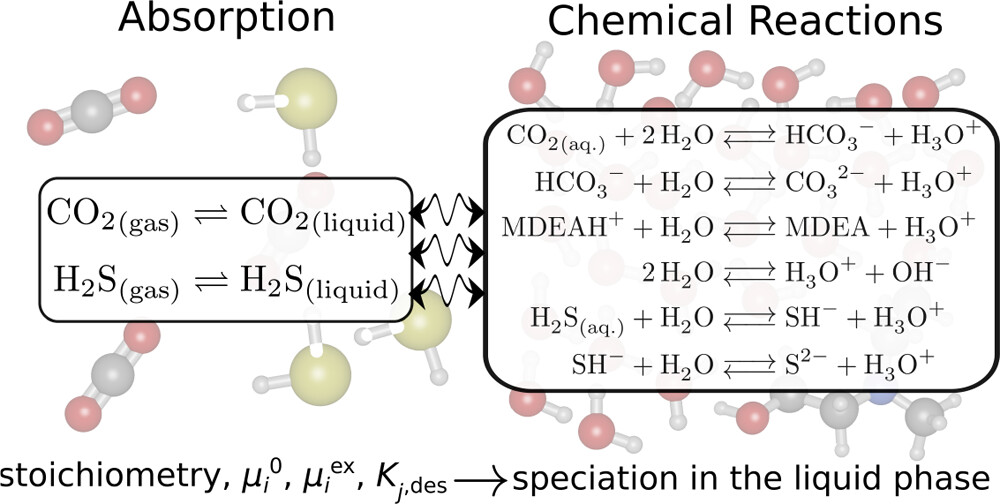

We developed an open-source chemical reaction equilibrium solver in Python (CASpy, github.com/omoultosEthTuDelft/CASpy) to compute the concentration of species in any reactive liquid-phase absorption system. We derived an expression for a mole fraction-based equilibrium constant as a function of excess chemical potential, standard ideal gas chemical potential, temperature, and volume. As a case study, we computed the CO2 absorption isotherm and speciation in a 23 wt % N-methyldiethanolamine (MDEA)/water solution at 313.15 K, and compared the results with available data from the literature. The results show that the computed CO2 isotherms and speciations are in excellent agreement with experimental data, demonstrating the accuracy and the precision of our solver. The binary absorptions of CO2 and H2S in 50 wt % MDEA/water solutions at 323.15 K were computed and compared with available data from the literature. The computed CO2 isotherms showed good agreement with other modeling studies from the literature while the computed H2S isotherms did not agree well with experimental data. The experimental equilibrium constants used as an input were not adjusted for H2S/CO2/MDEA/water systems and need to be adjusted for this system. Using free energy calculations with two different force fields (GAFF and OPLS-AA) and quantum chemistry calculations, we computed the equilibrium constant (K) of the protonated MDEA dissociation reaction. Despite the good agreement of the OPLS-AA force field (ln[K] = −24.91) with the experiments (ln[K] = −23.04), the computed CO2 pressures were significantly underestimated. We systematically investigated the limitations of computing CO2 absorption isotherms using free energy and quantum chemistry calculations and showed that the computed values of μiex are very sensitive to the point charges used in the simulations, which limits the predictive power of this method.

H. Mert Polat, Frédérick de Meyer, Céline Houriez, Othonas A. Moultos, and Thijs J. H. Vlugt

-

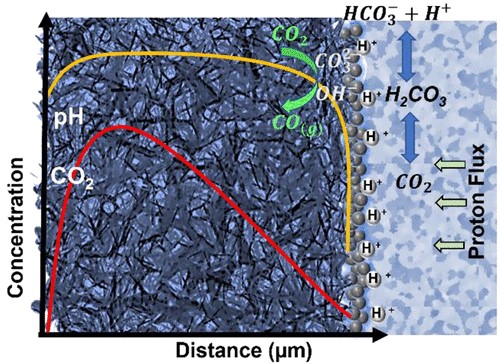

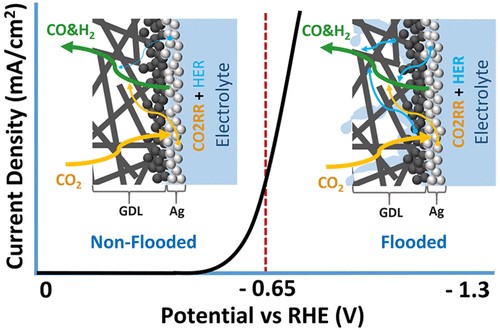

Electrochemical reduction of carbon dioxide (CO2) to useful products is an emerging power-to-X concept, which aims to produce chemicals and fuels with renewable electricity instead of fossil fuels. Depending on the catalyst, a range of chemicals can be produced from CO2 electrolysis at industrial-scale current densities, high Faraday efficiencies, and relatively low cell voltages. One of the main challenges for up-scaling the process is related to (bi)carbonate formation (carbonation), which is a consequence of performing the reaction in alkaline media to suppress the competing hydrogen evolution reaction. The parasitic reactions of CO2 with the alkaline electrolytes result in (bi)carbonate precipitation and flooding in gas diffusion electrodes, CO2 crossover to the anode, low carbon utilization efficiencies, electrolyte carbonation, pH-drift in time, and additional cost for CO2 and electrolyte recycling. We present a critical review of the causes, consequences, and possible solutions for the carbonation effect in CO2 electrolyzers. The mechanism of (bi)carbonate crossover in different cell configurations, its effect on the overall process design, and the economics of CO2 and electrolyte recovery are presented. The aim is to provide a better understanding of the (bi)carbonate problem and guide research directions to overcome the challenges related to low-temperature CO2 electrolysis in alkaline media.

Mahinder Ramdin, Othonas A. Moultos, Leo J. P. van den Broeke, Prasad Gonugunta, Peyman Taheri and Thijs J. H. Vlugt

-

The electrochemical CO2 reduction reaction (CO2RR) has been proposed as a sustainable way of closing the carbon cycle while synthesizing useful commodity chemicals. One of the possible routes to scale up the process is the elevated pressure CO2RR, as this increases the concentration of the poorly soluble CO2 in aqueous systems. Yet, there are not many studies that focus on this route owing to the inherent challenges with high pressure systems. In this study, a novel high pressure flow cell setup has been designed and validated. The modular design uses a clamp system, which facilitates simple stacking of multiple cell parts while being capable of handling pressures up to 50 bar. The effects of CO2 pressure on the reaction were investigated on a gold (Au) foil cathode in a 0.1 M KHCO3 electrolyte. We successfully measured gaseous products produced during high pressure operation using an inline gas chromatograph. We find that the selectivity toward CO2 reduction products is enhanced while that of H2 evolution is suppressed as the pressure is increased from 2 to 30 bar. The reported setup provides a robust means to conduct high pressure electrolysis experiments in an easy and safe manner, making this technology more accessible to the electrochemical CO2RR community.

Andrew R. T. Morrison, Nandalal Girichandran, Quincy Wols & Ruud Kortlever

-

Understanding multiphase flow close to the electrode surface is crucial to the design of electrolyzers, such as alkaline water electrolyzers for the production of green hydrogen. Vertical electrodes develop a narrow gas plume near their surface. We apply the integral method to the mixture model. Considering both exponentially varying and step-function gas fraction profiles, we derive analytical relations for plume thickness, velocity profile, and gas fraction near the electrode as a function of height and current density. We verify these analytical relations with the numerical solutions obtained using two-dimensional mixture model simulations. We find that for low gas fractions, the plume thickness decreases with an increase in current density for an exponentially varying gas fraction profile. In contrast, the plume thickness increases with increasing current density at high gas fractions for an approximately step-function-shaped gas fraction profile, in agreement with experiments from the literature.

A. Rajora, J.W. Haverkort

-

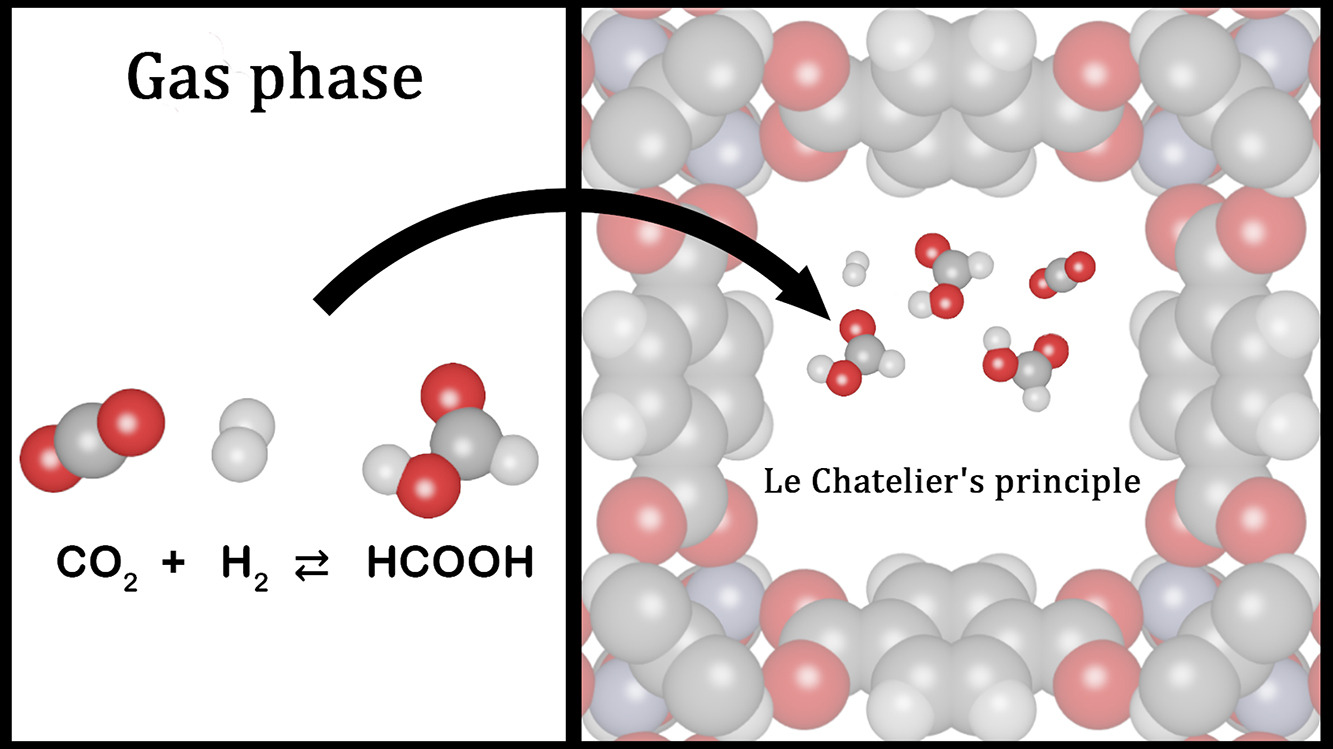

Formic acid production from CO2 allows the reduction of carbon dioxide emissions while synthesizing a product with a wide range of applications. CO2 hydrogenation is challenging due to the cost of transition metal catalysts and the toxicity of the transition elements. In this work, the thermodynamic confinement effects of the metal–organic framework UiO-66 on the CO2 hydrogenation to formic acid were studied by force field-based molecular simulations. The confinement effects of UiO-66 and the metal–organic frameworks Cu-BTC, and IRMOF-1 were compared, to assess the impact of different pore size and metal centers on the production of HCOOH. Monte Carlo simulations in the grand-canonical ensemble were performed in the frameworks, using gas phase mole fractions of CO2, H2, and HCOOH at chemical equilibrium, obtained from Continuous Fractional Component Monte Carlo simulations in the Reaction Ensemble. The adsorption isobars of the components in metal–organic frameworks were computed at 298.15 – 800 K, 1 – 60 bar. The enhancement of HCOOH production due to preferential adsorption of HCOOH in metal–organic frameworks was calculated for all studied conditions. UiO-66, Cu-BTC, and IRMOF-1 affect CO2 hydrogenation reaction, shifting the thermodynamical equilibrium toward HCOOH formation. The prevailing factor is the type of metal center in the metal–organic framework. The confinement effect of Cu-BTC turns out to exceed the enhancement caused by UiO-66, and IRMOF-1. The resulting mole fraction of HCOOH increased by ca. 2000 times compared to the gas phase at 298.15 K, 60 bar. Cu-BTC can be considered as an alternative to improve the production of HCOOH due to elimination of the high-cost temperature elevation, cost reduction of downstream processing methods, and comparable final concentration of HCOOH to the reported concentrations of formate obtained using transition metal catalysts.

Dominika O. Wasik, Ana Martín-Calvo, Juan José Gutiérrez-Sevillano, David Dubbeldam, Thijs J.H. Vlugt, Sofía Calero

-

Aqueous electrolytes are most commonly used for the CO2 reduction reaction (CO2RR), but suffer from a low CO2 solubility that limits the reaction. Electrochemical CO2 reduction in nonaqueous electrolytes can provide a solution, due to the higher CO2 solubility of organic solvent-based electrolytes. Herein, the product distribution of the electrochemical CO2 reduction on polycrystalline Cu in 0.7 m tetraethylammonium chloride in propylene carbonate with different water additions (0, 10, and 90 v%), and for different operating conditions (10, 25, 40, and 60 °C), is investigated. It is found that CO2 reduction on Cu in a propylene carbonate solution results in H2, CO, and formic acid formation only, even though Cu is known to produce C2+ products such as ethylene and ethanol in aqueous electrolytes. Increasing the operating temperature increases the CO2RR kinetics and shows an improvement in CO formation and decrease in H2 formation. However, increasing the operating temperature also increases water transport through the membrane, resulting in an increase of H2 formation over time when operating at 60 °C.

Iris Burgers, Elena Pérez-Gallent, Earl Goetheer, Ruud Kortlever

-

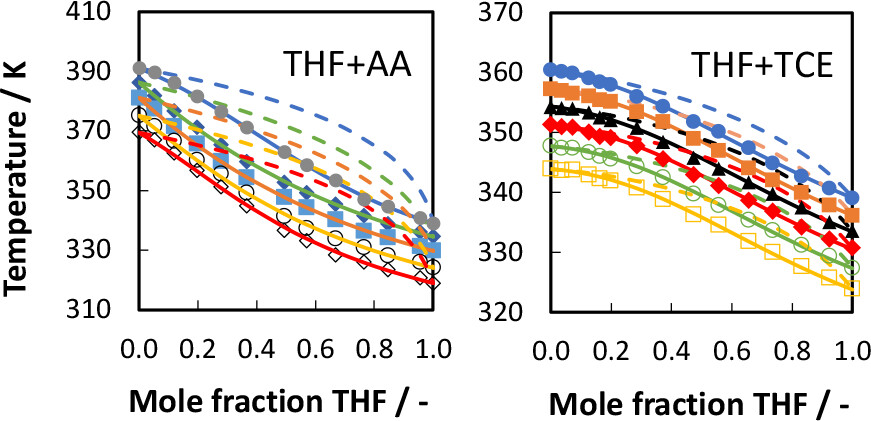

Vapor–liquid equilibrium (VLE) data for the binary systems tetrahydrofuran (THF) + acetic acid (AA) and THF + trichloroethylene (TCE) were measured under isobaric conditions using an ebulliometer. The boiling temperatures for the systems (THF + AA/THF + TCE) are reported for 13/15 compositions and five/six different pressures ranging from 50.2/60.0 to 101.1/101.3 kPa, respectively. The THF + AA system shows simple phase behavior with no azeotrope formation. The THF + TCE system does not exhibit azeotrope formation but seems to have a pinch point close to the pure end of TCE. The nonrandom two-liquid (NRTL) and universal quasichemical (UNIQUAC) activity coefficient models were used to accurately fit the binary (PTx) data. Both models were able to fit the binary VLE data satisfactorily. However, the NRTL model was found to be slightly better than UNIQUAC model in fitting the VLE data for both systems. The results can be used for designing liquid–liquid extraction and distillation processes involving mixtures of THF, AA, and TCE.

Vyomesh M. Parsana, Sachin Parikh, Keval Ziniya, Hirvita Dave, Piyush Gadhiya, Kedar Joshi, Dolly Gandhi, Thijs J. H. Vlugt, and Mahinder Ramdin

-

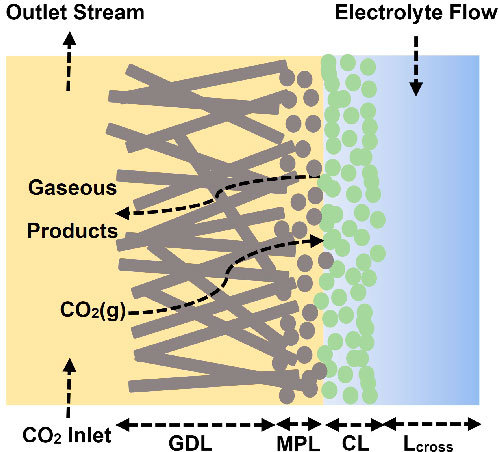

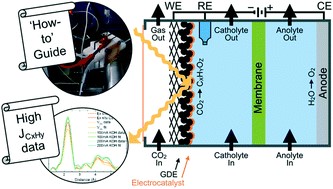

The use of gas diffusion electrodes that supply gaseous CO2 directly to the catalyst layer has greatly improved the performance of electrochemical CO2 conversion. However, reports of high current densities and Faradaic efficiencies primarily come from small lab scale electrolysers. Such electrolysers typically have a geometric area of 5 cm2, while an industrial electrolyser would require an area closer to 1 m2. The difference in scales means that many limitations that manifest only for larger electrolysers are not captured in lab scale setups. We develop a 2D computational model of both a lab scale and upscaled CO2 electrolyser to determine performance limitations at larger scales and how they compare to the performance limitations observed at the lab scale. We find that for the same current density larger electrolysers exhibit much greater reaction and local environment inhomogeneity. Increasing catalyst layer pH and widening concentration boundary layers of the KHCO3 buffer in the electrolyte channel lead to higher activation overpotential and increased parasitic loss of reactant CO2 to the electrolyte solution. We show that a variable catalyst loading along the direction of the flow channel may improve the economics of a large scale CO2 electrolyser.

J.W. Blake, V. Konderla, L.M. Baumgartner, D.A. Vermaas, J.T. Padding and J.W. Haverkort

-

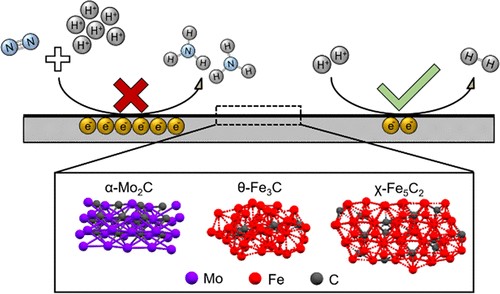

The electrochemical dinitrogen reduction reaction (NRR) has recently gained much interest as it can potentially produce ammonia from renewable intermittent electricity and replace the Haber–Bosch process. Previous literature studies report Fe- and Mo-carbides as promising electrocatalysts for the NRR with activities higher than other metals. However, recent understanding of extraneous ammonia and nitrogen oxide contaminations have challenged previously published results. Here, we critically assess the NRR performance of several Fe- and Mo-carbides reported as promising by implementing a strict experimental protocol to minimize the effect of impurities. The successful synthesis of α-Mo2C decorated carbon nanosheets, α-Mo2C nanoparticles, θ-Fe3C nanoparticles, and χ-Fe5C2 nanoparticles was confirmed by X-ray diffraction, scanning and transmission electron microscopy, and X-ray photoelectron and Mössbauer spectroscopy. After performing NRR chronoamperometric tests with the synthesized materials, the ammonia concentrations varied between 37 and 124 ppb and are in close proximity with the estimated ammonia background level. Notwithstanding the impracticality of these extremely low ammonia yields, the observed ammonia did not originate from the electrochemical nitrogen reduction but from unavoidable extraneous ammonia and NOx impurities. These findings are in contradiction with earlier literature studies and show that these carbide materials are not active for the NRR under the employed conditions. This further emphasizes the importance of a strict protocol in order to distinguish between a promising NRR catalyst and a false positive.

Boaz Izelaar, Davide Ripepi, Simone Asperti, A. Iulian Dugulan, Ruud W.A. Hendrikx, Amarante J. Böttger, Fokko M. Mulder and Ruud Kortlever

-

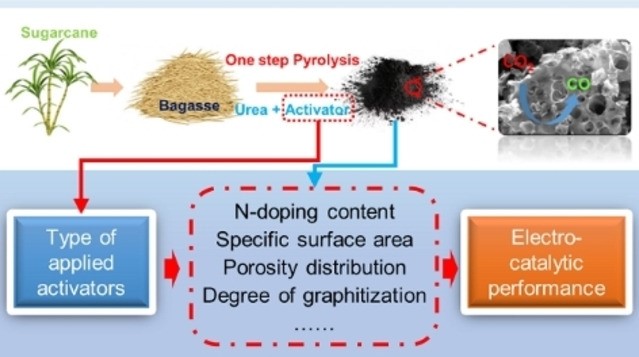

N-doped carbon materials can be efficient and cost-effective catalysts for the electrochemical CO2 reduction reaction (CO2RR). Activators are often used in the synthesis process to increase the specific surface area and porosity of these carbon materials. However, owing to the diversity of activators and the differences in physicochemical properties that these activators induce, the influence of activators used for the synthesis of N-doped carbon catalysts on their electrochemical performance is unclear. In this study, a series of bagasse-derived N-doped carbon catalysts is prepared with the assistance of different activators to understand the correlation between activators, physicochemical properties, and electrocatalytic performance for the CO2RR. The properties of N-doped carbon catalysts, such as N-doping content, microstructure, and degree of graphitization, are found to be highly dependent on the type of activator applied in the synthesis procedure. Moreover, the overall CO2RR performance of the synthesized electrocatalysts is not determined only by the N-doping level and the configuration of the N-dopant, but rather by the overall surface chemistry, where the porosity and the degree of graphitization are jointly responsible for significant differences in CO2RR performance.

Shilong Fu, Ming Li, Simone Asperti, Prof. Dr. Wiebren de Jong and Dr. Ruud Kortlever

-

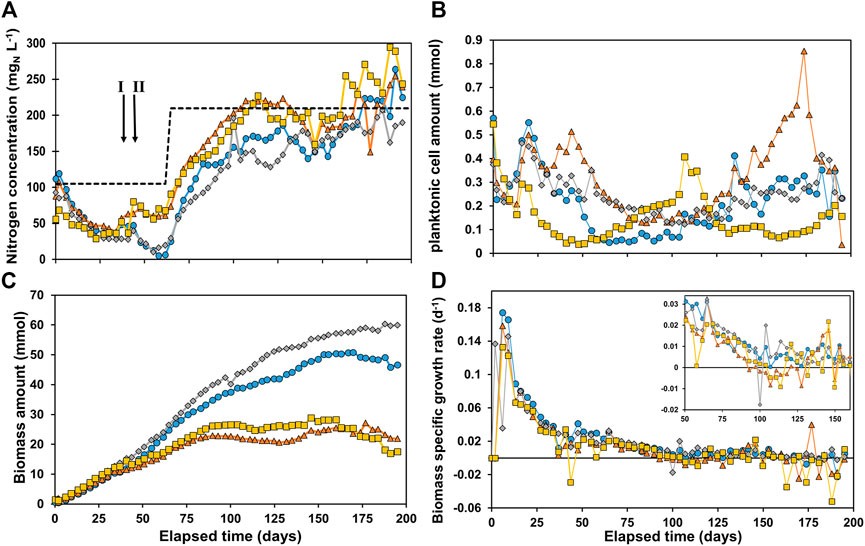

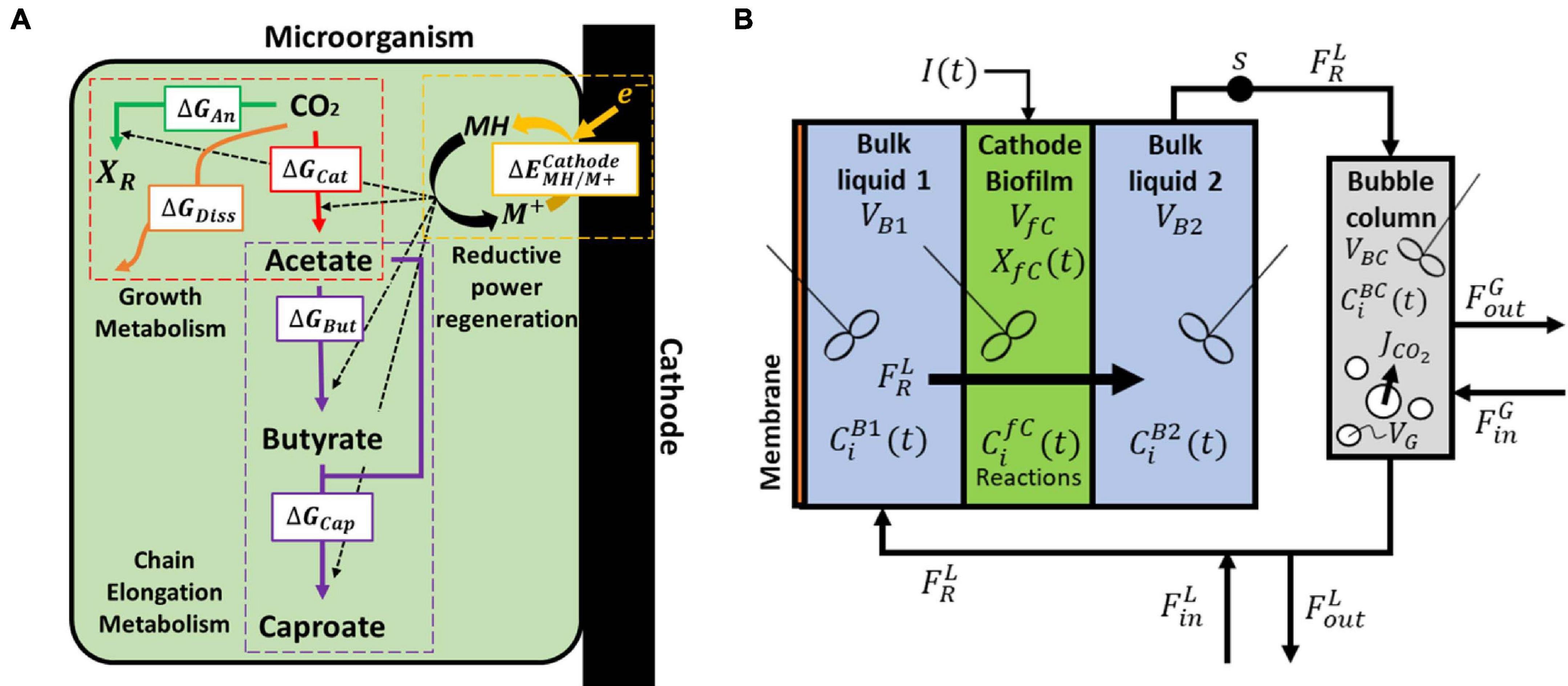

Microbial electrochemical technologies (METs) employ microorganisms utilizing solid-state electrodes as either electron sink or electron source, such as in microbial electrosynthesis (MES). METs reaction rate is traditionally normalized to the electrode dimensions or to the electrolyte volume, but should also be normalized to biomass amount present in the system at any given time. In biofilm-based systems, a major challenge is to determine the biomass amount in a non-destructive manner, especially in systems operated in continuous mode and using 3D electrodes. We developed a simple method using a nitrogen balance and optical density to determine the amount of microorganisms in biofilm and in suspension at any given time. For four MES reactors converting CO2 to carboxylates, >99% of the biomass was present as biofilm after 69 days of reactor operation. After a lag phase, the biomass-specific growth rate had increased to 0.12–0.16 days−1. After 100 days of operation, growth became insignificant. Biomass-specific production rates of carboxylates varied between 0.08–0.37 molC molX−1d−1. Using biomass-specific rates, one can more effectively assess the performance of MES, identify its limitations, and compare it to other fermentation technologies.

Marijn Winkelhorst, Oriol Cabau-Peinado, Adrie J.J. Straathof and Ludovic Jourdin

-

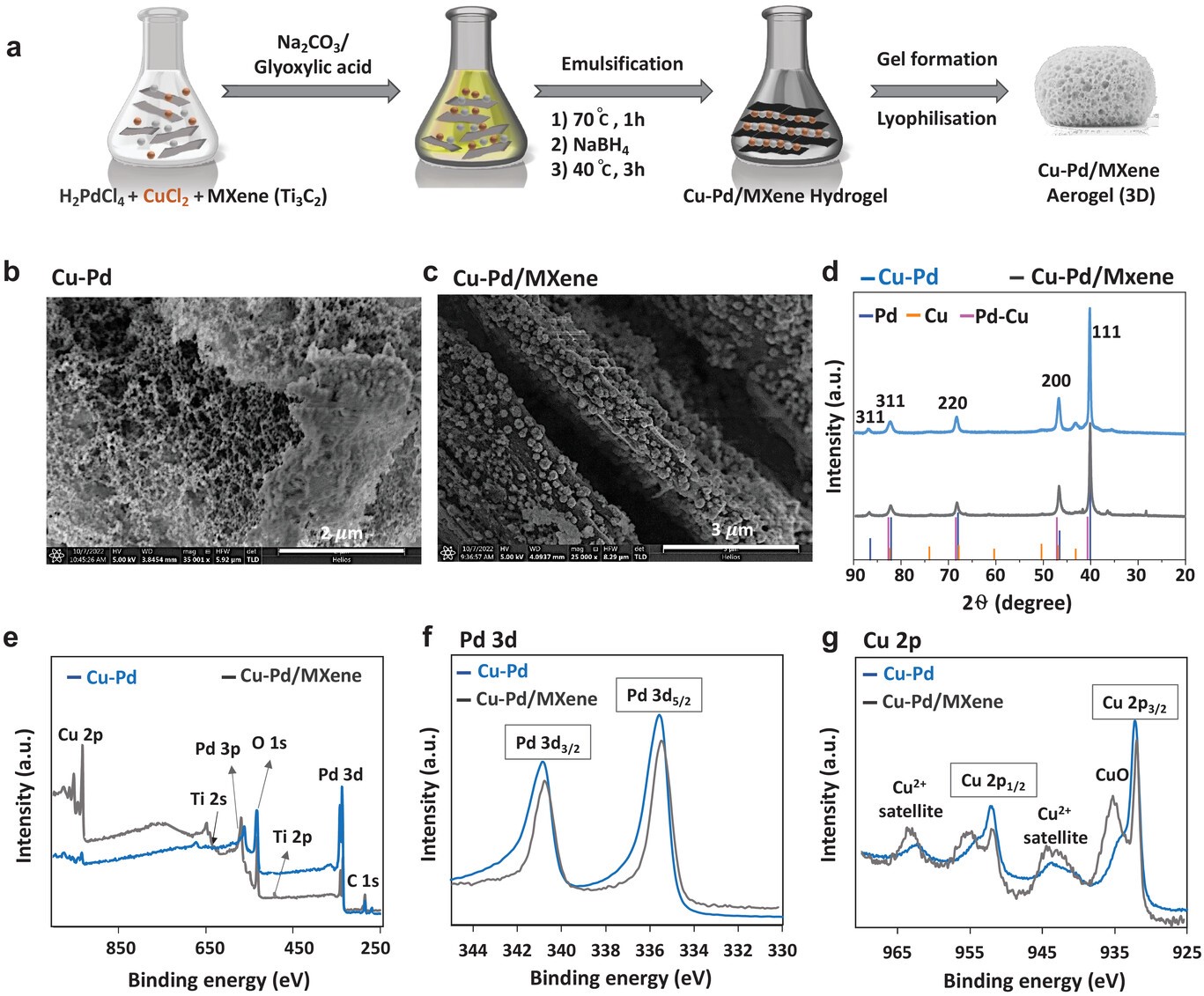

The electrochemical CO2 reduction reaction (CO2RR) is an attractive method to produce renewable fuel and chemical feedstock using clean energy sources. Formate production represents one of the most economical target products from CO2RR but is primarily produced using post-transition metal catalysts that require comparatively high overpotentials. Here a composition of bimetallic Cu–Pd is formulated on 2D Ti3C2Tx (MXene) nanosheets that are lyophilized into a highly porous 3D aerogel, resulting in formate production much more efficient than post-transition metals. Using a membrane electrode assembly (MEA), formate selectivities >90% are achieved with a current density of 150 mA cm−2 resulting in the highest ever reported overall energy efficiency of 47% (cell potentials of −2.8 V), over 5 h of operation. A comparable Cu-Pd aerogel achieves near-unity CO production without the MXene templating. This simple strategy represents an important step toward the experimental demonstration of 3D-MXenes-based electrocatalysts for CO2RR application and opens a new platform for the fabrication of macroscale aerogel MXene-based electrocatalysts.

M Abdinejad, S Subramanian, MK Motlagh, M Noroozifar, S Duangdangchote, I Neporozhnii, D Ripepi, D Pinto,aM Li, K Tang, J Middelkoop, A Urakawa, O Voznyy, HB Kraatz, T Burdyny.

-

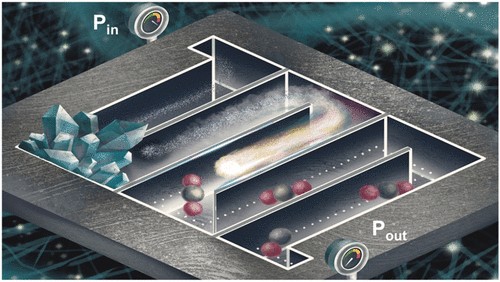

The electrochemical reduction of CO2 (CO2RR) on silver catalysts has been demonstrated under elevated current density, longer reaction times, and intermittent operation. Maintaining performance requires that CO2 can access the entire geometric catalyst area, thus maximizing catalyst utilization. Here we probe the time-dependent factors impacting geometric catalyst utilization for CO2RR in a zero-gap membrane electrode assembly. We use three flow fields (serpentine, parallel, and interdigitated) as tools to disambiguate cell behavior. Cathode pressure drop is found to play the most critical role in maintaining catalyst utilization at all time scales by encouraging in-plane CO2 transport throughout the gas-diffusion layer (GDL) and around salt and water blockages. The serpentine flow channel with the highest pressure drop is then the most failure-resistant, achieving a CO partial current density of 205 mA/cm2 at 2.76 V. These findings are confirmed through selectivity measurements over time, double-layer capacitance measurements to estimate GDL flooding, and transport modeling of the spatial CO2 concentration.

S Subramanian, K Yang, M Li, M Sassenburg, M Abdinejad, E Irtem, J Middelkoop, T Burdyny.

-

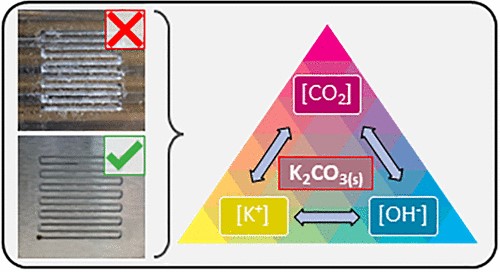

Salt precipitation is a problem in electrochemical CO2 reduction electrolyzers that limits their long-term durability and industrial applicability by reducing the active area, causing flooding and hindering gas transport. Salt crystals form when hydroxide generation from electrochemical reactions interacts homogeneously with CO2 to generate substantial quantities of carbonate. In the presence of sufficient electrolyte cations, the solubility limits of these species are reached, resulting in “salting out” conditions in cathode compartments. Detrimental salt precipitation is regularly observed in zero-gap membrane electrode assemblies, especially when operated at high current densities. This Perspective briefly discusses the mechanisms for salt formation, and recently reported strategies for preventing or reversing salt formation in zero-gap CO2 reduction membrane electrode assemblies. We link these approaches to the solubility limit of potassium carbonate within the electrolyzer and describe how each strategy separately manipulates water, potassium, and carbonate concentrations to prevent (or mitigate) salt formation.

M Sassenburg, M Kelly, S Subramanian, WA Smith, T Burdyny

-

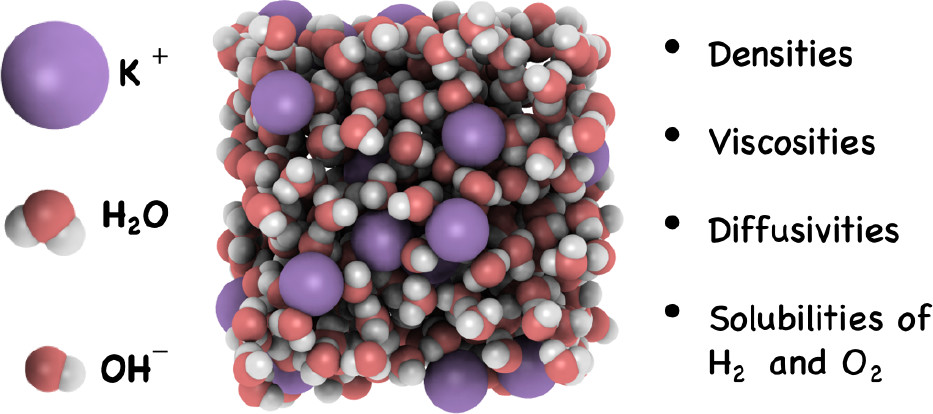

The thermophysical properties of aqueous electrolyte solutions are of interest for applications such as water electrolyzers and fuel cells. Molecular dynamics (MD) and continuous fractional component Monte Carlo (CFCMC) simulations are used to calculate densities, transport properties (i.e., self-diffusivities and dynamic viscosities), and solubilities of H2 and O2 in aqueous sodium and potassium hydroxide (NaOH and KOH) solutions for a wide electrolyte concentration range (0–8 mol/kg). Simulations are carried out for a temperature and pressure range of 298–353 K and 1–100 bar, respectively. The TIP4P/2005 water model is used in combination with a newly parametrized OH– force field for NaOH and KOH. The computed dynamic viscosities at 298 K for NaOH and KOH solutions are within 5% from the reported experimental data up to an electrolyte concentration of 6 mol/kg. For most of the thermodynamic conditions (especially at high concentrations, pressures, and temperatures) experimental data are largely lacking. We present an extensive collection of new data and engineering equations for H2 and O2 self-diffusivities and solubilities in NaOH and KOH solutions, which can be used for process design and optimization of efficient alkaline electrolyzers and fuel cells.

Parsa Habibi, Ahmadreza Rahbari, Samuel Blazquez, Carlos Vega, Poulumi Dey, Thijs J. H. Vlugt, and Othonas A. Moultos

-

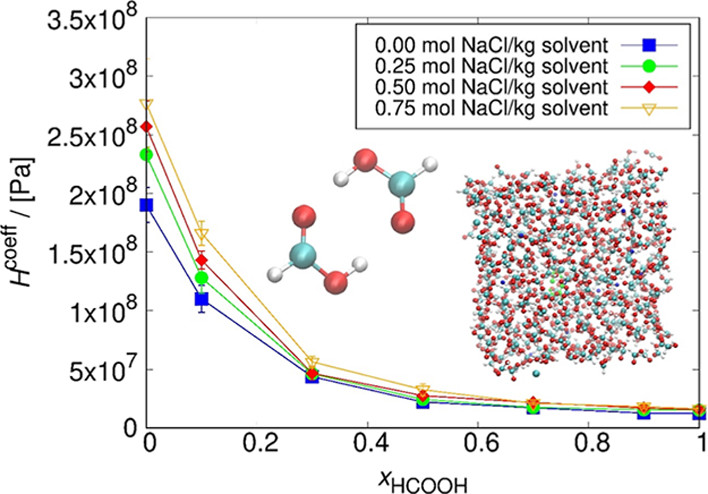

There is a growing interest in the development of routes to produce formic acid from CO2, such as the electrochemical reduction of CO2 to formic acid. The solubility of CO2 in the electrolyte influences the production rate of formic acid. Here, the dependence of the CO2 solubility in aqueous HCOOH solutions with electrolytes on the composition and the NaCl concentration was studied by Continuous Fractional Component Monte Carlo simulations at 298.15 K and 1 bar. The chemical potentials of CO2, H2O, and HCOOH were obtained directly from single simulations, enabling the calculation of Henry coefficients and subsequently considering salting in or salting out effects. As the force fields for HCOOH and H2O may not be compatible due to the presence of strong hydrogen bonds, the Gibbs–Duhem integration test was used to test this compatibility. The combination of the OPLS/AA force field with a new set of parameters, in combination with the SPC/E force field for water, was selected. It was found that the solubility of CO2 decreases with increasing NaCl concentration in the solution and increases with the increase of HCOOH concentration. This continues up to a certain concentration of HCOOH in the solution, after which the CO2 solubility is high and the NaCl concentration has no significant effect.

Dominika O. Wasik, H. Mert Polat, Mahinder Ramdin, Othonas A. Moultos, Sofia Calero, and Thijs J. H. Vlugt

-

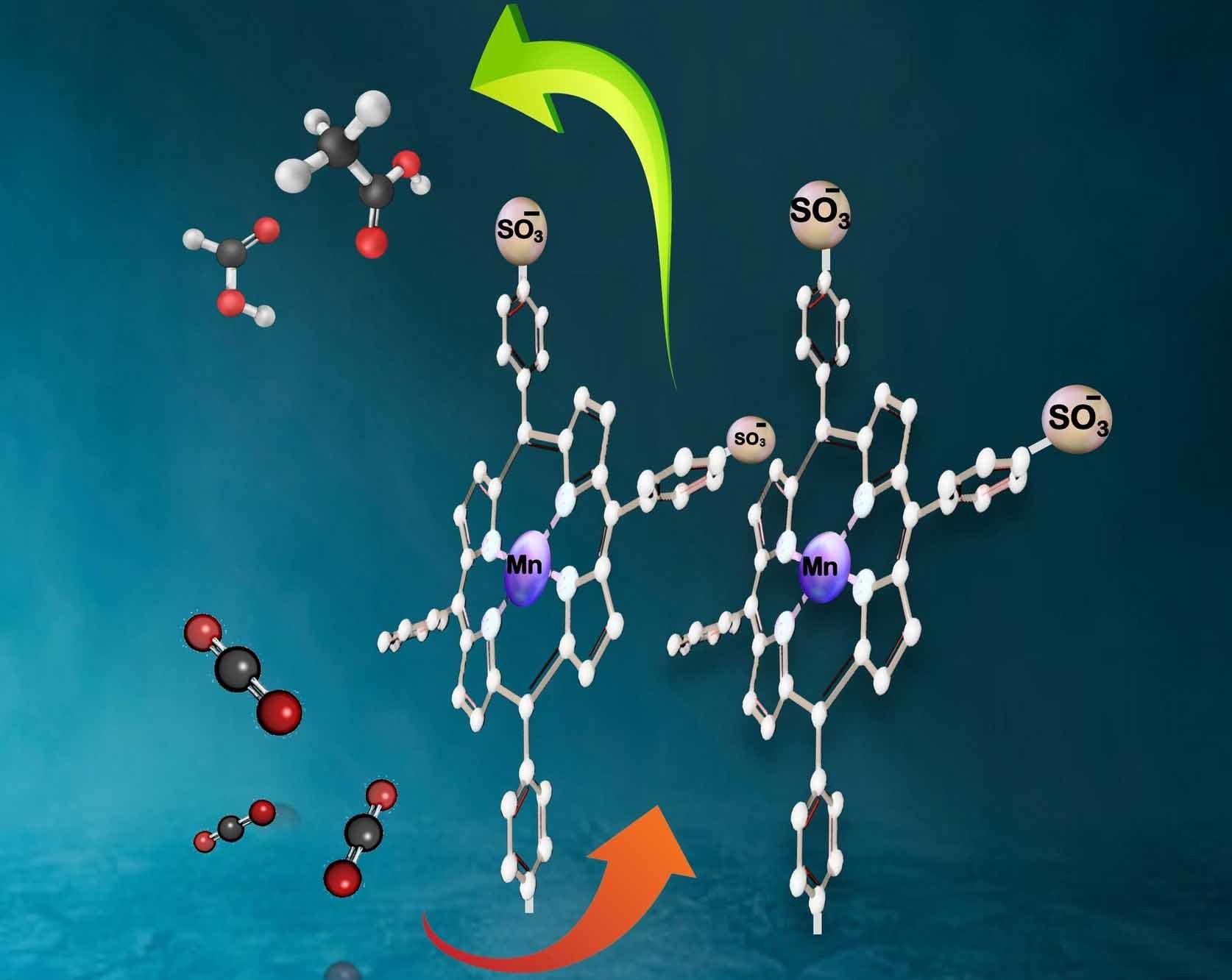

The electrochemical reduction of carbon dioxide (CO2) to value-added chemicals is a promising strategy to mitigate climate change. Metalloporphyrins have been used as a promising class of stable and tunable catalysts for the electrochemical reduction reaction of CO2 (CO2RR) but have been primarily restricted to single-carbon reduction products. Here, we utilize functionalized earth-abundant manganese tetraphenylporphyrin-based (Mn-TPP) molecular electrocatalysts that have been immobilized via electrografting onto a glassy carbon electrode (GCE) to convert CO2 with overall 94 % Faradaic efficiencies, with 62 % being converted to acetate. Tuning of Mn-TPP with electron-withdrawing sulfonate groups (Mn-TPPS) introduced mechanistic changes arising from the electrostatic interaction between the sulfonate groups and water molecules, resulting in better surface coverage, which facilitated higher conversion rates than the non-functionalized Mn-TPP. For Mn-TPP only carbon monoxide and formate were detected as CO2 reduction products. Density-functional theory (DFT) calculations confirm that the additional sulfonate groups could alter the C−C coupling pathway from *CO→*COH→*COH-CO to *CO→*CO-CO→*COH-CO, reducing the free energy barrier of C−C coupling in the case of Mn-TPPS. This opens a new approach to designing metalloporphyrin catalysts for two carbon products in CO2RR.

M. Abdinejad, T. Yuan, K. Tang, S. Duangdangchote, A. Farzi, H.P. Iglesias van Montfort, M. Li, J. Middelkoop, M. Wolff, A. Seifitokaldani, O. Voznyy, T. Burdyny

-

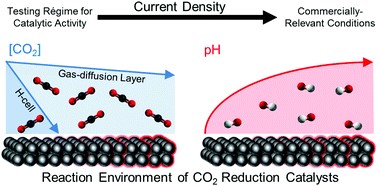

Electrochemical reduction of CO2 heavily depends on the reaction conditions found near the electrode surface. These local conditions are affected by phenomena such as electric double layer formation and steric effects of the solution species, which in turn impact the passage of CO2 molecules to the catalytic surface. Most models for CO2 reduction ignore these effects, leading to an incomplete understanding of the local electrode environment. In this work, we present a modeling approach consisting of a set of size-modified Poisson–Nernst–Planck equations and the Frumkin interpretation of Tafel kinetics. We introduce a modification to the steric effects inside the transport equations which results in more realistic concentration profiles. We also show how the modification lends the model numerical stability without adopting any separate stabilization technique. The model can replicate experimental current densities and faradaic efficiencies till −1.5 vs. SHE/V of applied electrode potential. We also show the utility of this approach for systems operating at elevated CO2 pressures. Using Frumkin-corrected kinetics gels well with the theoretical understanding of the double layer. Hence, this work provides a sound mechanistic understanding of the CO2 reduction process, from which new insights on key performance controlling parameters can be obtained.

Esaar Naeem Butt, Johan T. Padding and Remco Hartkamp

-

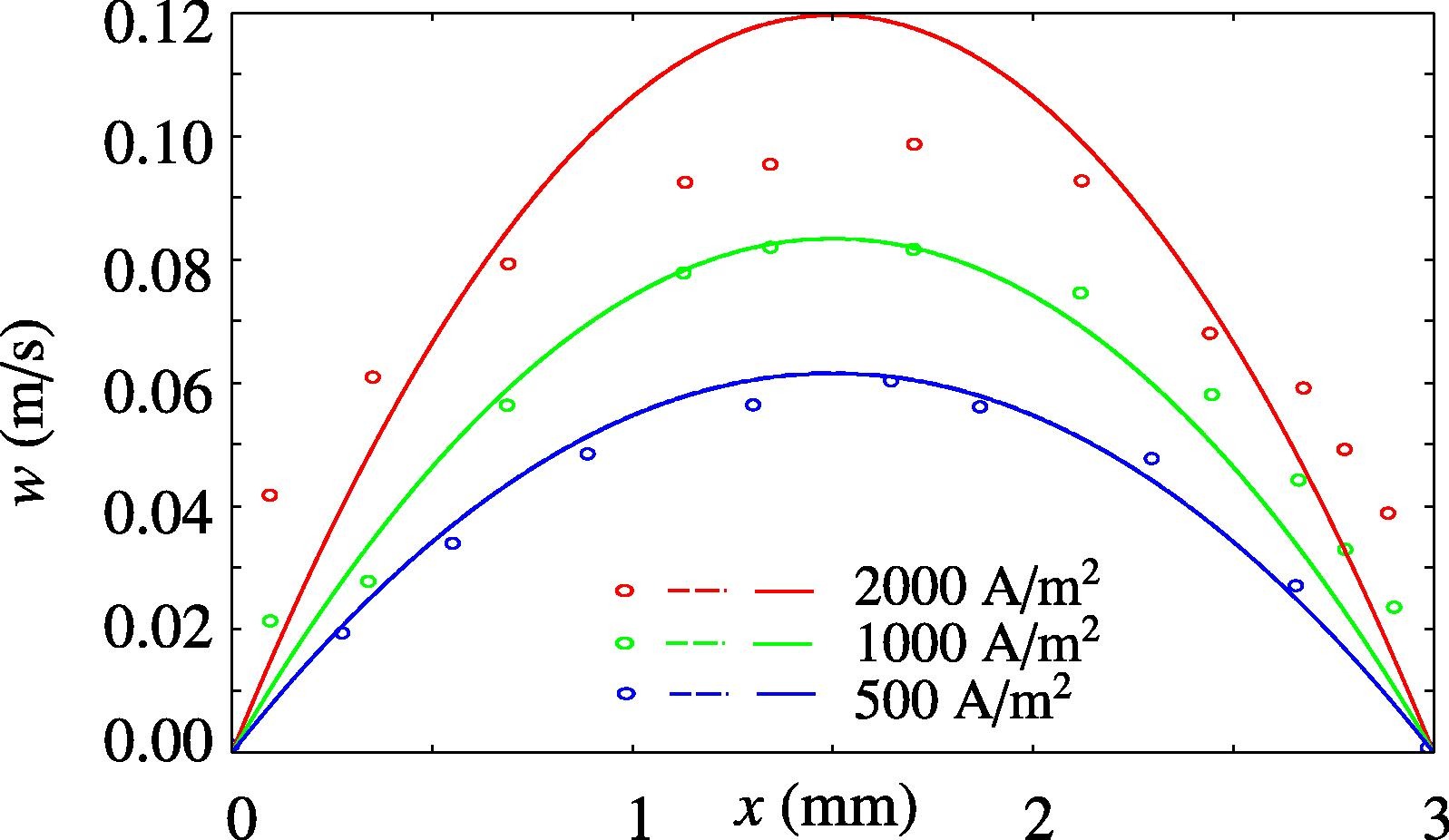

Membraneless parallel-plate electrolyzers use electrolyte flow to avoid product crossover. Using a mixture model neglecting inertia, and assuming an exponential gas fraction profile, we derive approximate analytical expressions for the velocity profile and pressure drop for thin plumes. We verify these expressions using numerical solutions obtained with COMSOL and validate them using experimental data from the literature. We find that the wall gas fraction increases rapidly at small heights, but becomes fairly constant at larger heights. These expressions serve as a guiding framework for designing a membraneless parallel-plate electrolyzer by quantifying the maximum possible height. We find that buoyancy driven membraneless parallel-plate electrolyzers with a 3 mm gap can be designed with a maximum height of around 7.6 cm at 1000 A/m2 for operation with 98% product purity at atmospheric pressure. For a forced flow at Re=1000, the same electrolyzer can be made around 17.6 cm tall at 1000 A/m2. These limits can be further improved with smaller bubbles or higher pressure.

A. Rajora and J.W. Haverkort

-

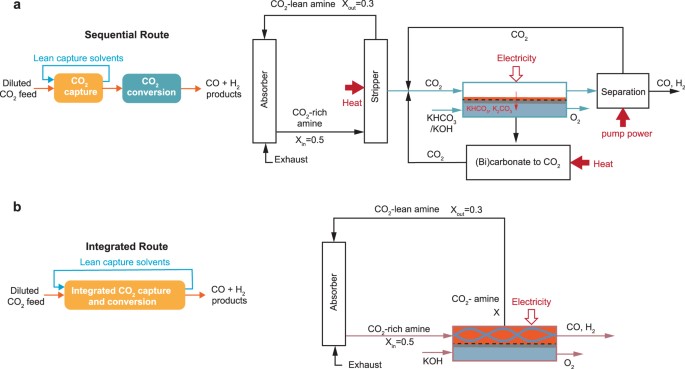

Integrating carbon dioxide (CO2) electrolysis with CO2 capture provides exciting new opportunities for energy reductions by simultaneously removing the energy-demanding regeneration step in CO2 capture and avoiding critical issues faced by CO2 gas-fed electrolysers. However, understanding the potential energy advantages of an integrated process is not straightforward due to the interconnected processes which require knowledge of both capture and electrochemical conversion processes. Here, we identify the upper limits of the integrated process from an energy perspective by comparing the working principles and performance of integrated and sequential approaches. Our high-level energy analyses unveil that an integrated electrolyser must show similar performance to the gas-fed electrolyser to ensure an energy benefit of up to 44% versus the sequential route. However, such energy benefits diminish if future gas-fed electrolysers resolve the CO2 utilisation issue and if an integrated electrolyser shows lower conversion efficiencies than the gas-fed system.

Mengran Li, Erdem Irtem, Hugo-Pieter Iglesias van Montfort, Maryam Abdinejad & Thomas Burdyny

-

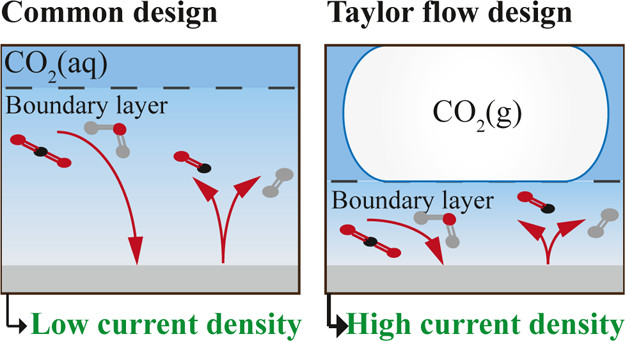

Electrochemical reduction of CO2 using renewable energy is a promising avenue for sustainable production of bulk chemicals. However, CO2 electrolysis in aqueous systems is severely limited by mass transfer, leading to low reactor performance insufficient for industrial application. This paper shows that structured reactors operated under gas–liquid Taylor flow can overcome these limitations and significantly improve the reactor performance. This is achieved by reducing the boundary layer for mass transfer to the thin liquid film between the CO2 bubbles and the electrode. This work aims to understand the relationship between process conditions, mass transfer, and reactor performance by developing an easy-to-use analytical model. We find that the film thickness and the volume ratio of CO2/electrolyte fed to the reactor significantly affect the current density and the faradaic efficiency. Additionally, we find industrially relevant performance when operating the reactor at an elevated pressure beyond 5 bar. We compare our predictions with numerical simulations based on the unit cell approach, showing good agreement for a large window of operating parameters, illustrating when the easy-to-use predictive expressions for the current density and faradaic efficiency can be applied.

Isabell Bagemihl, Chaitanya Bhatraju, J. Ruud van Ommen and Volkert van Steijn

-

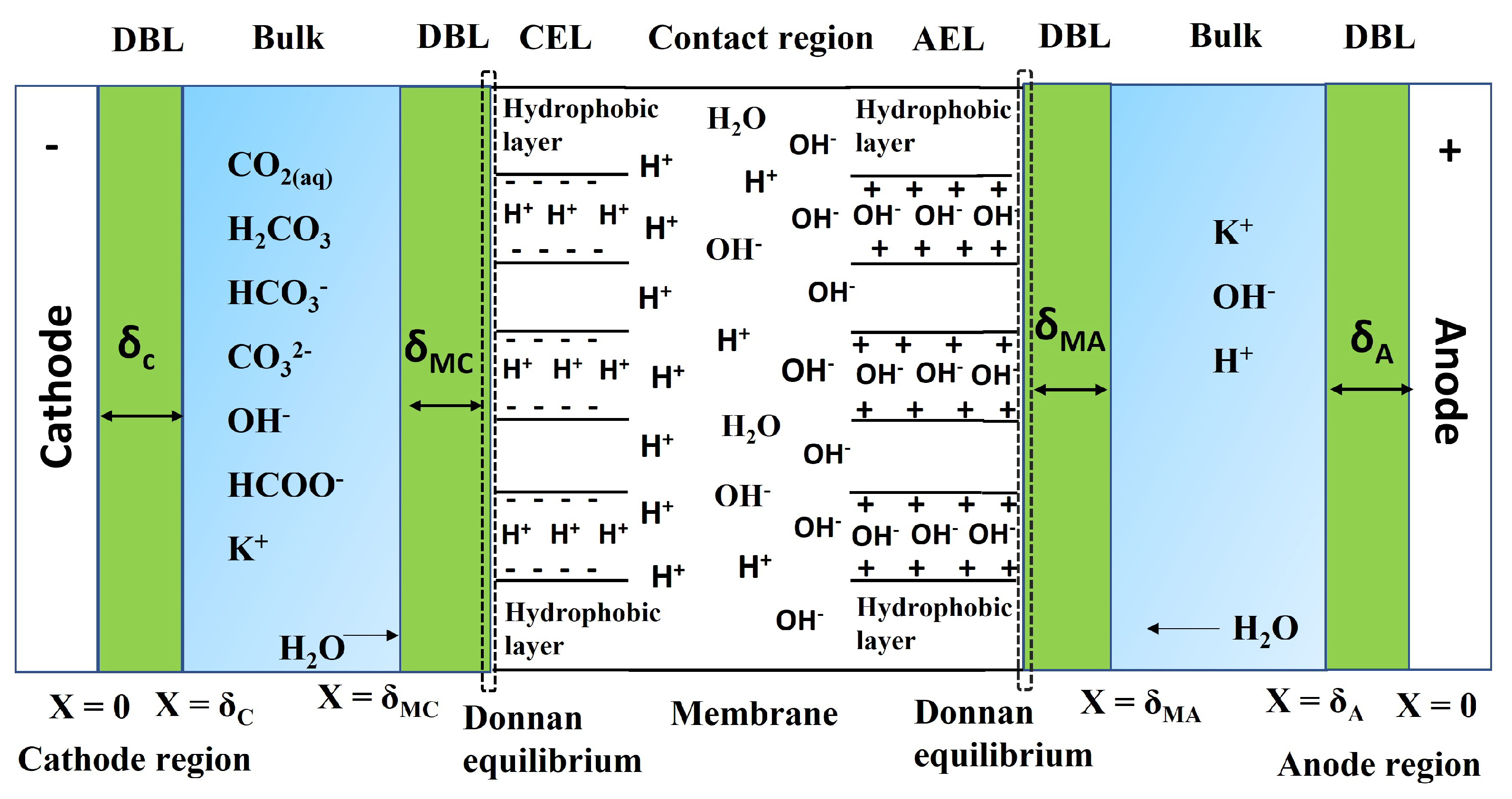

Mass transport of different species plays a crucial role in electrochemical conversion of CO2 due to the solubility limit of CO2 in aqueous electrolytes. In this study, we investigate the transport of CO2 and other ionic species through the electrolyte and the membrane, and its impact on the scale-up process of HCOO−/HCOOH formation. The mass transport of ions to the electrode and the membrane is modelled at constant current density. The mass transport limitations of CO2 on the formation of HCOO−/HCOOH is investigated at different pressures ranges from 5–40 bar. The maximum achievable partial current density of formate/formic acid is increased with increasing CO2 pressure. We use an ion exchange membrane model to understand the ion transport behaviour for both the monopolar and bipolar membranes. The cation exchange (CEM) and anion exchange membrane (AEM) model show that ion transport is limited by the electrolyte salt concentrations. For 0.1 M KHCO3, the AEM reaches the limiting current density more quickly than the CEM. For the BPM model, ion transport across the diffusion layer on either side of the BPM is also included to understand the concentration polarization across the BPM. The model revealed that the polarization losses across the bipolar membrane depend on the pH of the electrolyte used for the CO2 reduction reaction (CO2RR). The polarization loss on the anolyte side decreases with an increasing pH, while, on the cathode side, it increases with increasing catholyte pH. With this combined model for the electrode reactions and the membrane transport, we are able to account for the various factors influencing the polarization losses in the CO2 electrolyzer. To complete the analysis, we simulated the full cell polarization curve and fitted with the experimental data.

Selvaraj Chinnathambi, Mahinder Ramdin and Thijs J. H. Vlugt

-

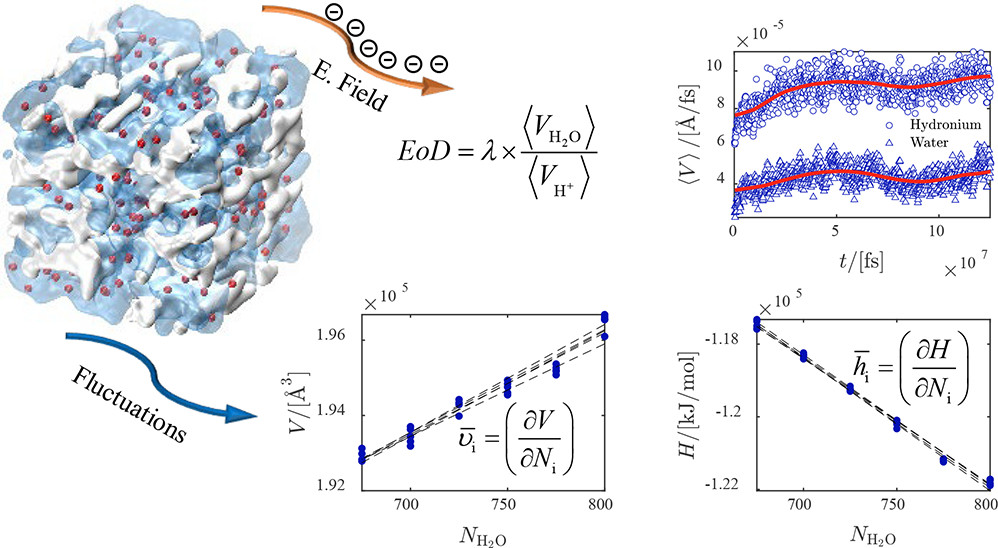

One of the important parameters in water management of proton exchange membranes is the electro-osmotic drag (EOD) coefficient of water. The value of the EOD coefficient is difficult to justify, and available literature data on this for Nafion membranes show scattering from in experiments and simulations. Here, we use a classical all-atom model to compute the EOD coefficient and thermodynamic properties of water from molecular dynamics simulations for temperatures between 330 and 420 K, and for different water contents between λ = 5 and λ = 20. λ is the ratio between the moles of water molecules to the moles of sulfonic acid sites. This classical model does not capture the Grotthuss mechanism; however, it is shown that it can predict the EOD coefficient within the range of experimental values for λ = 5 where the vehicular mechanism dominates proton transfer. For λ > 5, the Grotthuss mechanism becomes dominant. To obtain the EOD coefficient, average velocities of water and ions are computed by imposing different electric fields to the system. Our results show that the velocities of water and hydronium scale linearly with the electric field, resulting in a constant ratio of ca. 0.4 within the error bars. We find that the EOD coefficient of water linearly increases from 2 at λ = 5 to 8 at λ = 20 and the results are not sensitive to temperature. The EOD coefficient at λ = 5 is within the range of experimental values, confirming that the model can capture the vehicular transport of protons well. At λ = 20, due to the absence of proton hopping in the model, the EOD coefficient is overestimated by a factor of 3 compared to experimental values. To analyze the interactions between water and Nafion, the partial molar enthalpies and partial molar volumes of water are computed from molecular dynamics simulations. At different water uptakes, multiple linear regression is used on raw simulation data within a narrow composition range of water inside the Nafion membrane. The partial molar volumes and partial molar excess enthalpies of water asymptotically approach the molar volumes and molar excess enthalpies of pure water for water uptakes above 5. This confirms the model can capture the bulklike behavior of water in the Nafion at high water uptakes.

Ahmadreza Rahbari, Remco Hartkamp, Othonas A. Moultos, Albert Bos, Leo J. P. van den Broeke, Mahinder Ramdin, David Dubbeldam, Alexey V. Lyulin, and Thijs J. H. Vlugt

-

The selective separation of ions is a major technological challenge having far-ranging impacts from product separation in electrochemical production of base chemicals from CO2 to water purification. In recent years, ion-selective electrochemical systems leveraging redox-materials emerged as an attractive platform based on their reversibility and remarkable ion selectivity. In the present study, we present an ultrasound-intensified fabrication process for polyvinyl ferrocene (PVF)–functionalized electrodes in a carbon nanotube (CNT) matrix for selective electro-adsorption of formate ions. To this end, a response surface methodology involving the Box–Behnken design with three effective independent variables, namely, PVF to CNT ratio, sonication duration, and ultrasonic amplitude was applied to reach the maximum formate adsorption efficiency. The fabricated electrodes were characterized using cyclic voltammetry.

Sevgi Polat, Ruud Kortlever, Huseyin Burak Eral

-

The electrochemical CO2 reduction reaction (CO2RR) is important for a sustainable future. Key insights into the reaction pathways have been obtained by density functional theory (DFT) analysis, but so far, DFT has been unable to give an overall understanding of selectivity trends without important caveats. We show that an unconsidered parameter in DFT models of electrocatalysts─the surface coverage of reacting species─is crucial for understanding the CO2RR selectivities for different surfaces. Surface coverage is a parameter that must be assumed in most DFT studies of CO2RR electrocatalysts, but so far, only the coverage of nonreacting adsorbates has been treated. Explicitly treating the surface coverage of reacting adsorbates allows for an investigation that can more closely mimic operating conditions. Furthermore, and of more immediate importance, the use of surface coverage-dependent adsorption energies allows for the extraction of ratios of adsorption energies of CO2RR intermediates (COOHads and HCOOads) that are shown to be predictive of selectivity and are not susceptible to systematic errors. This approach allows for categorization of the selectivity of several monometallic catalysts (Pt, Pd, Au, Ag, Zn, Cu, Rh, W, Pb, Sn, In, Cd, and Tl), even problematic ones such as Ag or Zn, and does so by only considering the adsorption energies of known intermediates. The selectivity of the further reduction of COOHads can now be explained by a preference for Tafel or Heyrovsky reactions, recontextualizing the nature of selectivity of some catalysts. In summary, this work resolves differences between DFT and experimental studies of the CO2RR and underlines the importance of surface coverage.

Andrew R. T. Morrison, Mahinder Ramdin, Leo J. P. van der Broeke, Wiebren de Jong, Thijs J. H. Vlugt, and Ruud Kortlever

-