How do we protect aircrafts against corrosion?

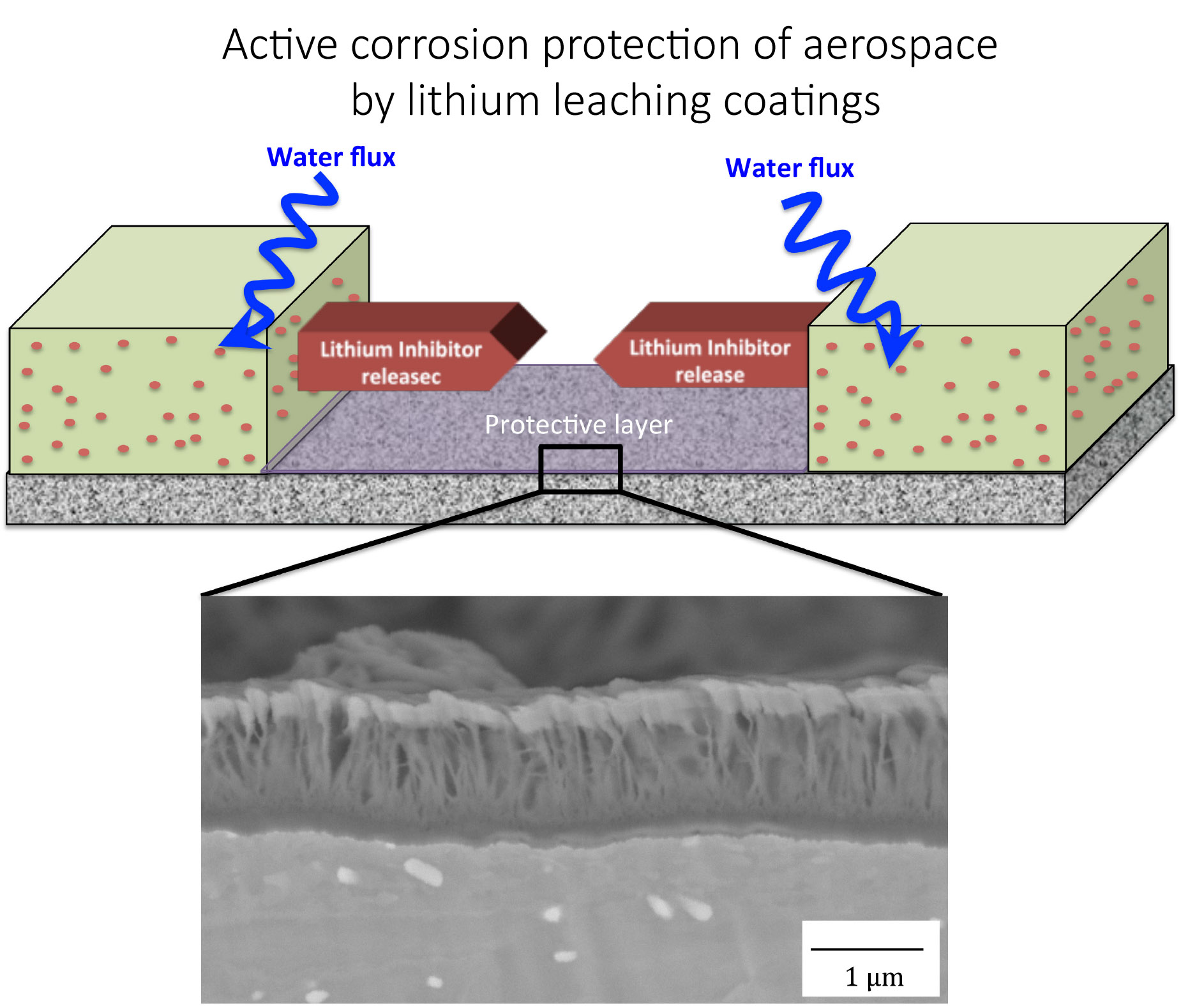

Peter Visser, PhD-candidate at the department of Materials Science and Engineering, conducts his research on a safe and environmentally friendly alternative for the toxic chromate corrosion inhibitors in active protective coatings for the protection of aerospace aluminium alloys. This week he showed the results of his promotion research “Active corrosion protection of aerospace aluminium alloys by lithium-leaching coatings”, which demonstrate that Li-leaching coatings possess the key criteria necessary for fast and effective corrosion inhibition and that Li-salts are promising corrosion inhibitors which potentially can become a new class of corrosion inhibitors for the chromate-free protection of aluminium alloys.

AkzoNobel

Peter Visser is performing his research in cooperation with AkzoNobel, where he;s working as the innovation project leader at the AkzoNobel Expertise Center Corrosion. At the of 2018 he has been awarded as AkzoNobel’s Scientist of the Year. Read more: Peter Visser is Scientist of the Year

The results from this research

For decades, scientists and engineers are searching for a safe and environmentally friendly alternative for the toxic chromate corrosion inhibitors in active protective coatings for the protection of aerospace aluminium alloys, but no alternative with equal or better performance compared to chromates has been found yet. In 2010 it was discovered that organic coatings loaded with lithium-salts as leachable corrosion inhibitor provided very effective and promising corrosion inhibition on aluminium alloys when exposed to industrial accelerated corrosion tests. Initial investigations showed the formation of a corrosion protective layer with a characteristic three-layered morphology layer on the aluminium alloy in a defect area, this appeared to be a key feature of these Li-leaching coatings.

The scientific objective of this PhD thesis was to gain understanding of the layer formation mechanism and to link its chemical and physical properties with corrosion protective performance of these layers when generated in a defect area from Li-leaching coatings. The knowledge and understanding of this mechanism is essential for the future industrial development and implementation of this novel active protective coating technology for the protection of aluminium alloys in the aerospace industry.

Het wetenschappelijke doel van dit proefschrift was om een beter begrip te verkrijgen van het mechanisme van de laagvorming en tevens om een verband te leggen tussen de chemische en fysische eigenschappen en de corrosiewerende werking van deze lagen, gedurende de vorming op het aluminium substraat in een coating defect vanuit de lithium-leaching coatings. De kennis en het begrip van dit vormingsmechanisme is essentieel voor de toekomstige industriële ontwikkeling en implementatie van deze nieuwe actief beschermende coatingtechnologie voor de bescherming van aluminiumlegeringen in de luchtvaartindustrie.