Designing hydrogen embrittlement-resistant steels based on combined modelling-experimental approach Subtitle:

Assistant Professors Dr. Poulumi Dey and Dr. Vera Popovich, from the Department of Materials Science and Engineering (MSE) at TU Delft, together with Assistant Professor Dr. Francesco Maresca from the Engineering and Technology Institute (ENTEG) of the University of Groningen (RUG), have been awarded a Materials Challenge Grant to design hydrogen embrittlement resistant steels.

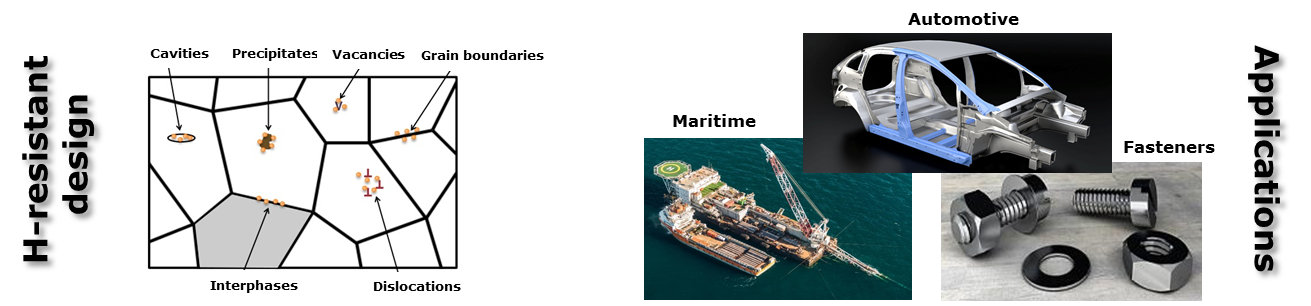

The focus of the project is to tackle hydrogen embrittlement (HE) in steels, which is one of the most challenging phenomena to understand. HE is an outstanding problem in the mechanics of structural metals which results in the loss of mechanical properties, such as strength and deformability, when hydrogen is present in metals or the surrounding environment (water, acids, …). The understanding and mitigating of HE has become a pressing need because of its significant societal and industrial impact. HE is one of the primary reasons why the ‘hydrogen economy’ could not be brought into reality till date. In spite of the numerous scientific efforts, the ambiguity related to fundamental mechanisms behind hydrogen embrittlement still persists.

Research Programme

The proposed research programme will provide deeper insights into the underlying mechanisms of hydrogen embrittlement. The project approach consists in the Multi-scale modelling-experimentation synergy based on Density Functional Theory, Molecular Dynamics, Crystal Plasticity and advanced experimental characterization that will connect atomistic information with the microstructural behaviour of multi-phase steels in presence of hydrogen, enabling design of new steels that are resistant to hydrogen embrittlement. The novel methodology developed within the project for steels, will be transferrable to other technologically relevant materials e.g. superalloys and the novel high-entropy alloys. The project is supported by a consortium of industrial partners Tata Steel, Allseas Engineering, Koninklijke Nedschroef Holding and Daimler.

The findings of the project will shed light on the fundamentals of HE phenomenon in multi-phase alloys, and will demonstrate the power of multi-scale predictive modelling as a paradigm shift for understanding and controlling HE along with the production of new HE-resistant materials. The study will further increase the application of steel in light-weight applications with efficient use of scarce micro alloying elements.