Research 3D print graded microstructures published in Additive Manufacturing

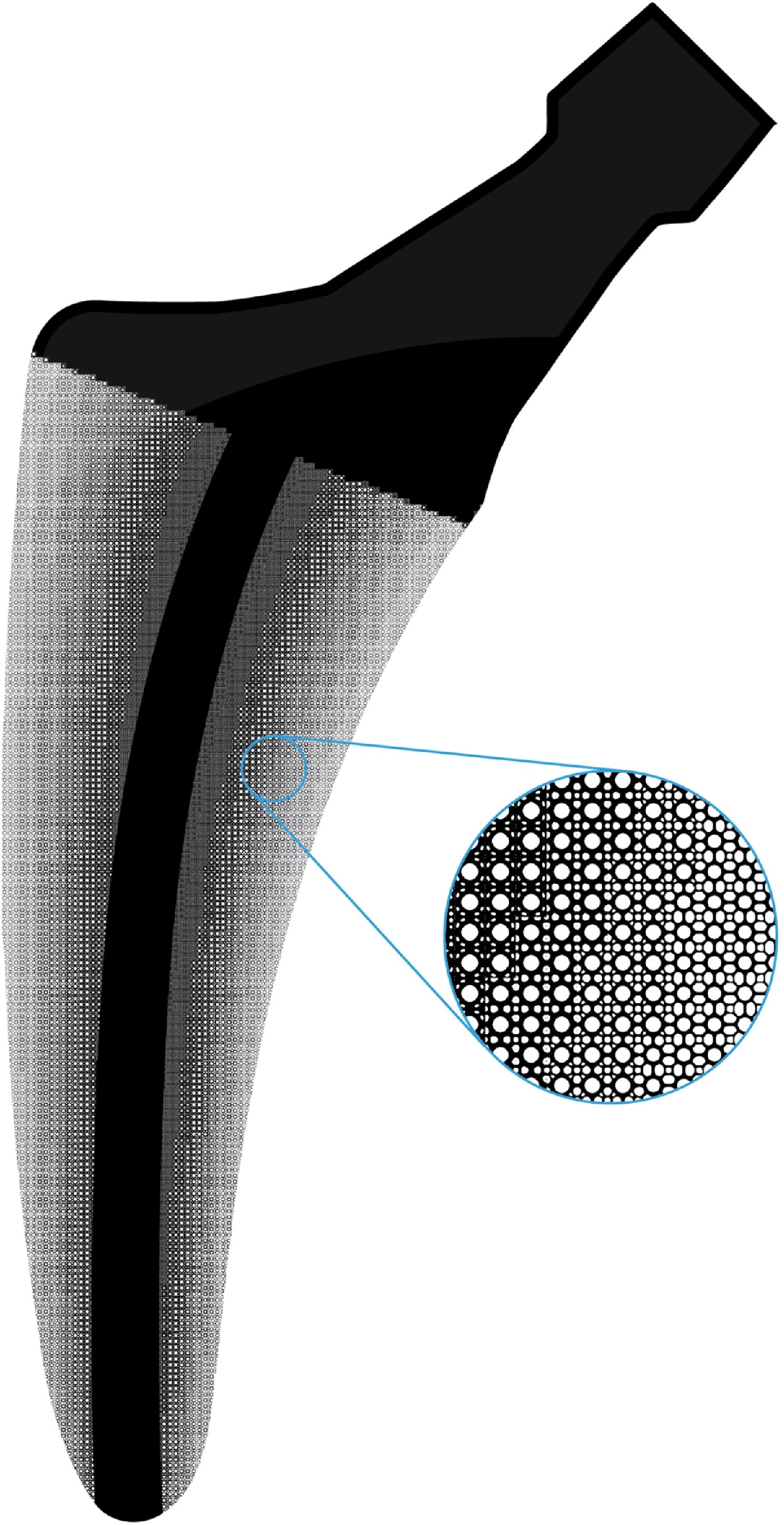

Researchers Jun Wu and Charlie Wang of Industrial Design Engineering, and Eric Garner, Helena Kolken and Amir Zadpoor of Biomechanical Engineering from 3ME (TU Delft) have developed a new type of functionally graded microstructures for 3D printing. This would enable 3D printed implants to better accommodate natural bony ingrowth, letting implants ‘merge’ better with your body.

Functionally graded microstructures are of great importance in product design. For instance, when designing orthopaedic implants, it may be desirable to have a continuous transition from denser microstructures in the central region to highly porous microstructures at the bone-implant interface. This functional gradation promotes bony ingrowth at the bone-implant interface, while maintaining structural integrity and increasing the mechanical properties in the areas where bony ingrowth is irrelevant.

Solving microstructure connectivity

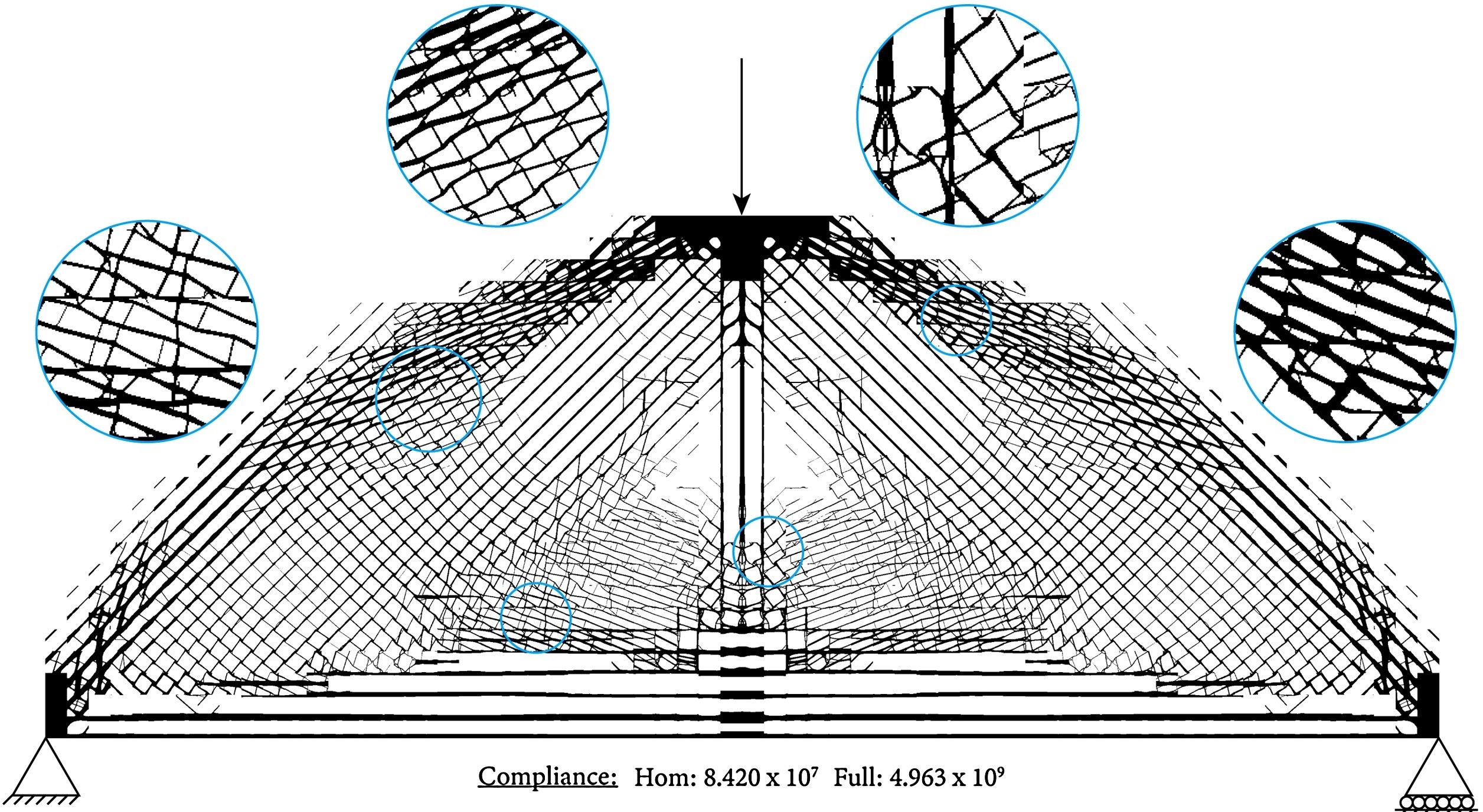

Functionally graded microstructures are also useful in multiscale structural optimisation, where poor connectivity across neighbouring microstructures has recently received considerable attention in academia.

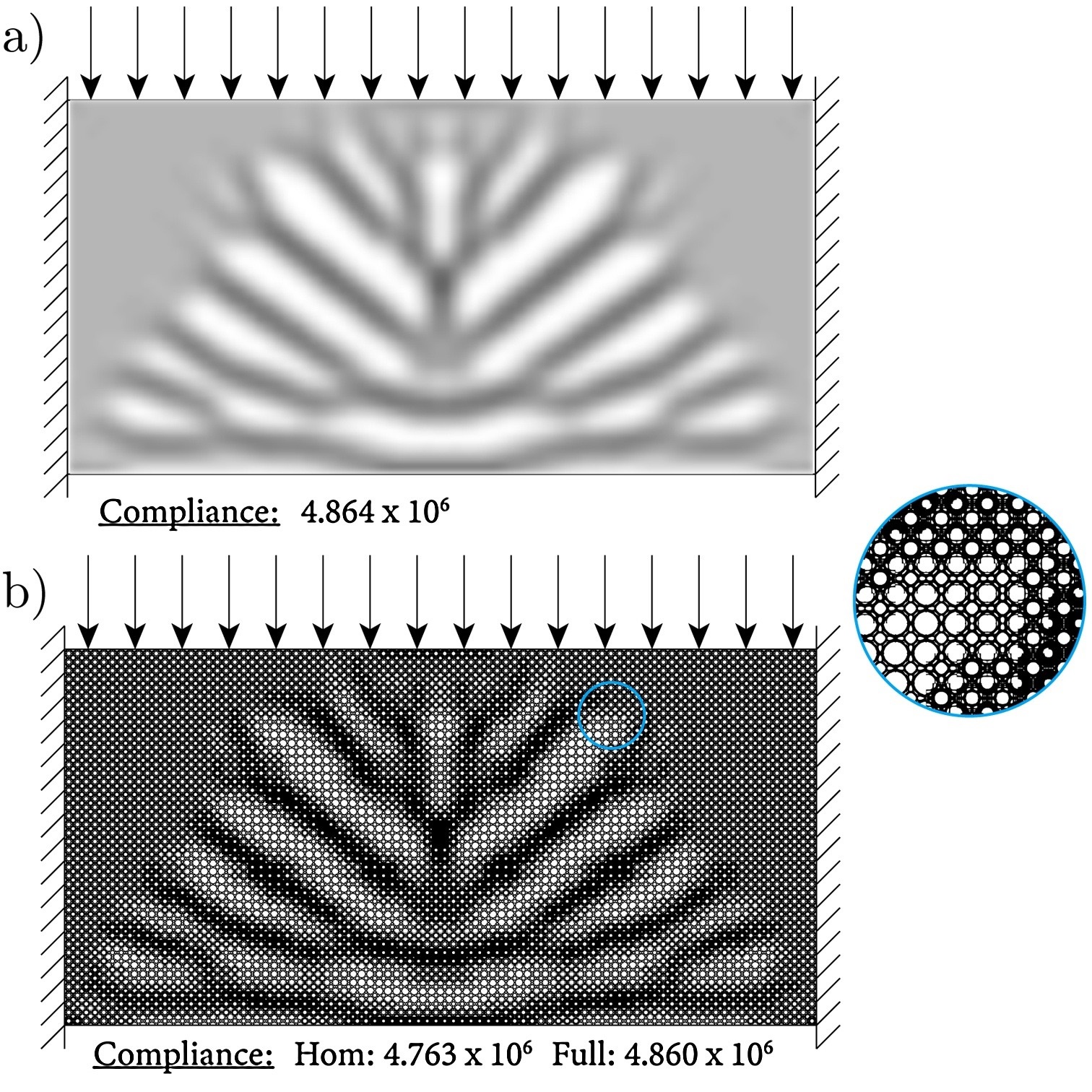

The Delft researchers have applied the new microstructures in a bottom-up topology optimisation process. Here, the new microstructures are used to replace the grey densities resulting from a density-based topology optimisation approach (see under, left). The researchers have further tested the new formulation in a concurrent topology optimization process (see under, right). Detailed evaluation and comparison with alternative approaches can be found in the paper 'Compatibility in microstructural optimization for additive manufacturing'. This work is published in the Additive Manufacturing journal.

Jun Wu

- +31 (0)15 27 84858

- j.wu-1@tudelft.nl

- Personal webpage

-

Room 32-B-3-030

"Make things as simple as possible, but not simpler." - Albert Einstein