The shape of things to come

IDE researchers were awarded second place in the 'Best Paper' category at the Symposium on Solid and Physical Modeling (SPM), part of the International Geometry Summit 2019. The winning paper is coauthored by PhD student Tim Kuipers (Ultimaker), and his supervisors Jun Wu and Charlie Wang (promotor).

SPM is the prime international venue for disseminating state-of-the-art research in the field of computer-aided design. Solid and Physical Modeling (SPM) 2019 is co-located in Vancouver with the Geometric Modeling and Processing conference (GMP), the SIAM conference on Computational Geometric Design, and Shape Modeling International (SMI) as part of the International Geometry Summit in 2019.

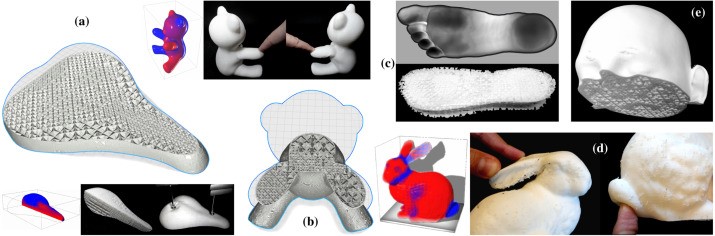

Various examples of applications of CrossFill. (a) A bicycle saddle with a density specification. A weight of 33 N is added on various locations to show the different response of different density infill. (b) A teddy bear with a density specification. (c) A shoe sole with densities based on a pressure map of a foot. (d) The Stanford bunny painted with a density specification. (e) A medical phantom with an example density distribution for calibrating an MRI scanning procedure.

In this work, the researchers present a type of microstructure which follows a user specified density field. Particularly interesting is that these density graded microstructures can be printed using continuous extrusion, so that we can generate infill structures which to be printed reliably by standard desktop Fused Deposition Modelling (FDM) printers. This is the first algorithm in the world which is able to generate spatially graded microstructures while adhering to continuous extrusion in order to ensure printing reliability.

This method – a novel type of FDM printable foam structure – offers a way to refine the structure to match a prescribed density distribution, and provides a novel self-supporting, space-filling surface to support spatially graded density, as well as an algorithm that can merge an infill structure’s toolpath with the model’s boundary for continuity. This space-filling infill surface is called CrossFill, as the toolpath resembles crosses.

Publication

Tim Kuipers, Jun Wu, and Charlie Wang. ‘Crossfill: Foam structures with graded density for continuous material extrusion’ in Computer-Aided Design 114 (2019): 37-50.

This research work is reported in 3dprint.com: Collaborative Research Team Develops Density-Graded Structure for Extrusion 3D Printing of Functionally Graded Materials

More information