Tuning quantum materials with hydrogen gas

Researchers at TU Delft have discovered a method to stretch and compress quantum materials using hydrogen gas. They demonstrated this effect using a tiny string of a material called tungsten trioxide, which acts as a sponge for hydrogen. The research is a promising new step in the development of micromechanical resonators, which have a wide range of possible applications. They can be used in inkjet printers, as sensors for environmental conditions, and as active components in future nano-electronics.

Quantum materials are among the most promising building blocks for smart devices of the future. What makes these materials special is that they can be controlled on-demand by several external parameters, for instance by heating or cooling, through the use of an electrical current, or by applying mechanical pressure. The magnetic and electronic properties of these materials can often be controlled dynamically, leading to the development of crucial components such as memories and energy-harvesting devices.

A new control tool

A limitation of quantum materials is that their mechanical properties can usually only be controlled through static methods. This means that once the device is designed and produced, its mechanical characteristics cannot be changed. Researchers Nicola Manca and Giordano Mattoni overcame this problem by using a new tool: hydrogen gas.

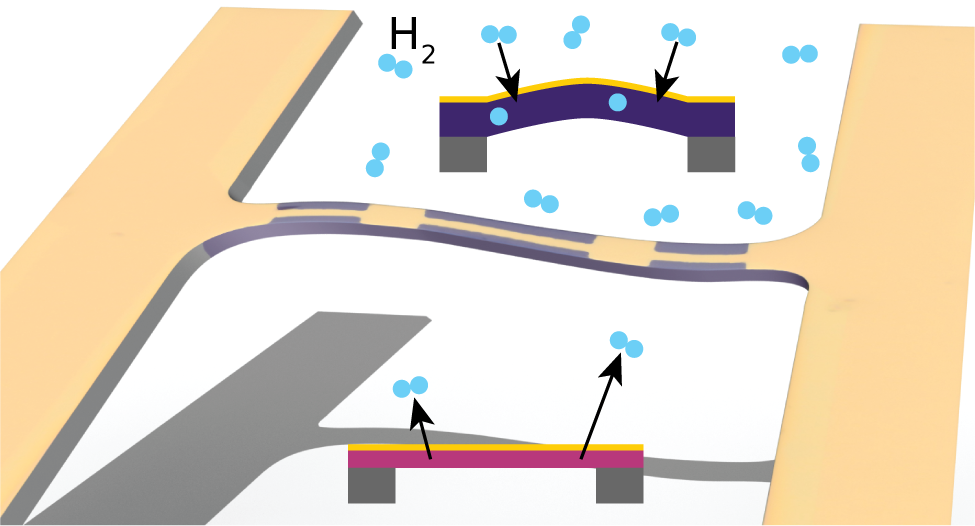

The researchers made use of tungsten trioxide, a crystalline material that can easily host hydrogen into its crystal lattice. “Tungsten trioxide quickly absorbs hydrogen gas”, says materials expert Giordano Mattoni. “This produces a large expansion of the crystal structure, similar to what happens when you put a dry sponge in water.” The process is fully reversible and, again like a sponge, the material expels hydrogen when exposed to pure air. This makes it possible to control its mechanical properties.

Micromechanical resonatorUsing high-quality material synthesis and the advanced nanofabrication facilities at TU Delft, the researchers manufactured a thin suspended structure of tungsten trioxide: a so-called micromechanical resonator. The structure showed large mechanical changes after the absorption of hydrogen gas. “It felt like we were tuning a guitar string”, says Nicola Manca, an expert on micromechanical resonators. “Hydrogen gas was able to modulate the resonance frequency of the material by more than 500 percent.” The strain modulation was so large that the induced changes could be observed with a common microscope. The more hydrogen went into the material, the more it expanded and bent.

The WO3 microstructure, initially out-of-focus due to the bending caused by the hydrogen, and then stretching out due to the release of hydrogen.

Room temperature

One of the main advantages of this technique is that it can be used at room temperature, in a controlled environment. It is also fully reversible. As a reference, obtaining a similar strain modulation with conventional methods and materials, such as thermal expansion in silicon, would require a temperature increase of more than 1500 degrees.

TU Delft has a pending patent application on the interaction of H2 with WO3 and is planning further research in this promising direction.

***

More information: N. Manca, G. Mattoni et al. Large tunability of strain in WO3 single-crystal microresonators controlled by exposure to H2 gas, ACS Applied Materials and Interfaces (2019).

DOI: 10.1021/acsami.9b14501