Important subsidy paves way towards emission-free gas turbines

TU Delft and partners Ansaldo Thomassen, OPRA Turbines, Vattenfall, Nouryon and EMMTEC have been awarded with a subsidy by the Dutch Government for the project ‘High Hydrogen Gas Turbine Retrofit to Eliminate Carbon Emissions’. The subsidy, valued at €500k, is granted as part of the Dutch hydrogen program within the Top Sector Energy area of the Dutch Ministry of Economic Affairs and Climate Policy. The program focuses on future carbon free hydrogen value chains in line with European Commission 2050 Energy Strategy Directives.

Hydrogen can deliver a carbon free solution for industry, mobility, housing and the power sector. The ambition of the program is to enable joint innovation between Dutch companies and institutes to be able to deliver economic value in the short to medium term. This project fits perfectly within the ambitions and objectives of the hydrogen program.

Fuel flexible and stable operation

The major objective of the High Hydrogen Retrofit Project is to develop a cost-effective ultra-low emissions (sub 9ppm NOx and CO) combustion system retrofit for existing installed gas turbines in the output range of 1MW to 300MW. Fuel flexibility and stable operation from 100% natural gas to 100% hydrogen and any mixture thereof, is a key requirement. This is a key challenge as extreme changes in fuel reactivity switching from natural gas to hydrogen can result in dramatic shifting of heat release within the combustor, which can be physically destructive if not well controlled.

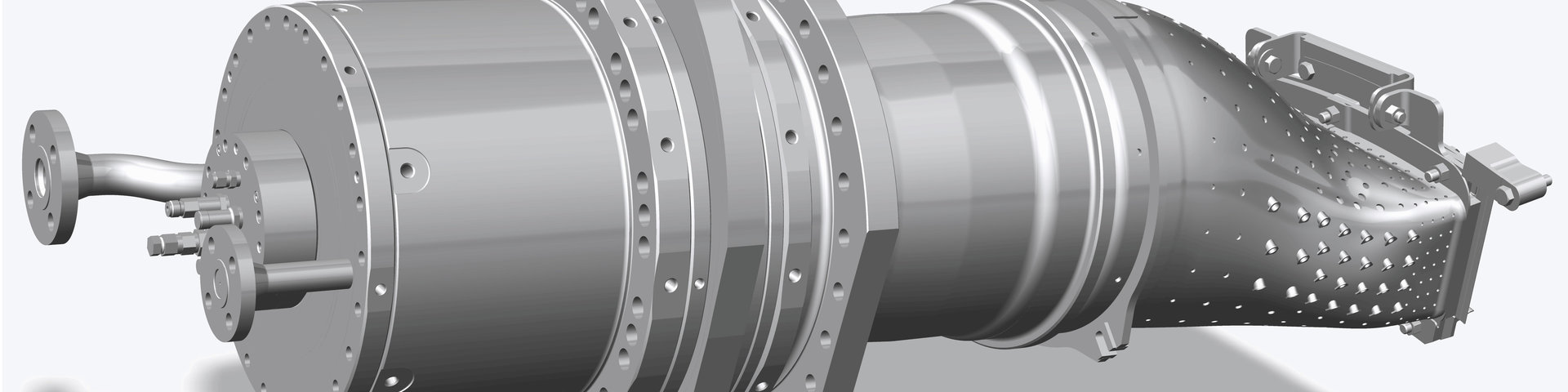

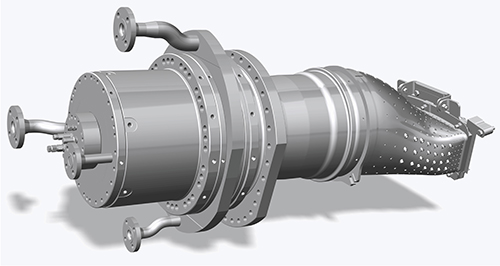

At the center of this innovative high-technology project is the patented and novel aerodynamic trapped vortex FlameSheetTM combustion technology platform, owned by Genoa Italy-based Ansaldo Energia. The FlameSheetTM combustion system is operating commercially in multiple 60hz F-Class gas turbine power plants with sub-9ppm NOx emissions including with the use of a hydrogen- blended fuel mix.

The prime focus of this award is a full-scale atmospheric verification in 2020, which will ultimately lead to a first engine demonstrator by 2023.

Contribution partners to the project

The lead applicant, Ansaldo Thomassen B.V. is an experienced expert in high technology gas turbine retrofits. Delft University of Technology provides advanced theoretical, computational and experimental experience in support of advanced high hydrogen combustion development. OPRA is a manufacturer of gas turbines with access to state-of-the-art test facilities which will play an important role in the project. The knowledge from this project will enable the power plant operator partners Vattenfall, EMMTEC and Nouryon, to make significant progress in the realization of dry low NOx, carbon free production of power and heat. Hydrogen generated from renewable energy resources such as excess wind and solar will also allow existing gas turbine power plants to become part of the large-scale energy storage solution.

More information

Contact Ansaldo Energia: Huub Koeman, Marketing Communication Specialist, Ansaldo Thomassen, phone: +31 (0)26 4975925, E-mail: huub.koeman@ath.ansaldoenergia.com

Contact TU Delft: Sikke Klein (Professor Gasturbines), s.a.klein@tudelft.nl, +31 (0)6 159 65844

Websites partners:

https://www.ansaldoenergia.com/ansaldo-thomassen

https://www.tudelft.nl/

https://www.opraturbines.com/

https://www.nouryon.com/

https://www.emmtecservices.nl/

https://group.vattenfall.com/

Photo: Ansaldo’s Multi-OEM Platform Gas Turbine Services FlameSheet™ Combustion Retrofit Solution