Growing tomatoes using artificial intelligence

Autonomous Greenhouse Challenge encourages the development of autonomous greenhouses

In a fully automated greenhouse in Bleiswijk, artificial intelligence is competing with humans. Various teams are growing cherry tomatoes as part of the second edition of the Autonomous Greenhouse Challenge. There are currently five teams left over in the competition. Who can grow the best tomatoes for the most profit?

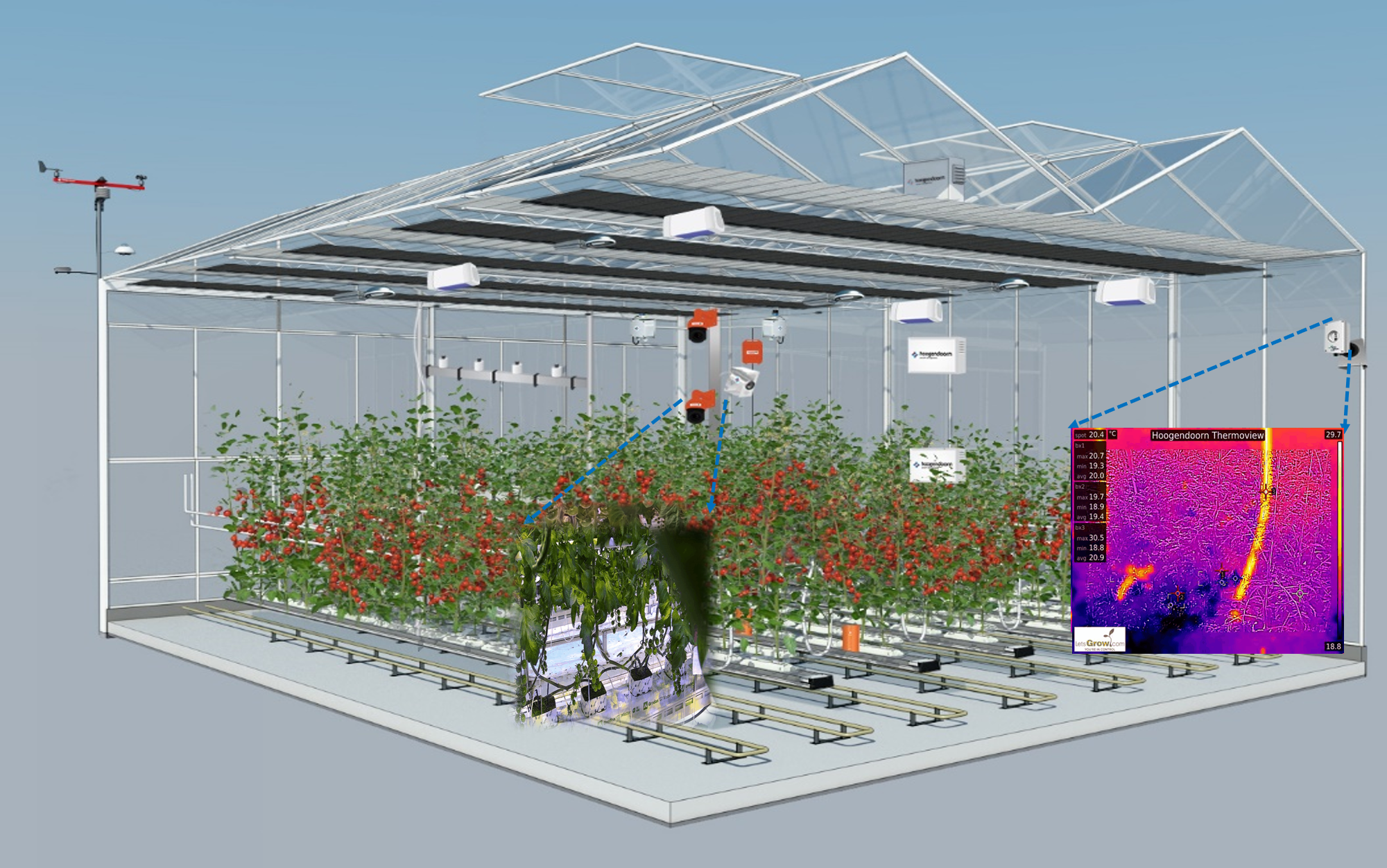

From December to May, the finalists will grow tomatoes in a special compartment in the greenhouse. Each compartment contains lots of sensors for measuring temperature, light, humidity and CO2 concentration. The data collected by all these sensors is forwarded to the teams, who use a computer with an algorithm they have developed themselves. The computer controls the greenhouse based on the data provided by the sensors.

One of the greatest challenges for the teams is that they are not allowed to enter the greenhouse. All the teams must grow the tomatoes remotely using artificial intelligence. In a separate compartment, horticulturalists are growing tomatoes using traditional methods for comparison.

It will become difficult to find properly trained personnel to manage the greenhouses and crops

The challenge was organised by Wageningen University & Research. TU Delft is strongly represented this year with finalists ‘The Automatoes’. We spoke with The Automatoes’ team members Leonard Baart de la Faille and Neil Yorke-Smith about the challenge.

Baart de la Faille is team captain and an R&D engineer with Van der Hoeven, a company that designs and sells greenhouses all over the world. De la Faille also has an appointment at TU Delft, where he forms a useful link between the University and the business community.

Yorke-Smith is Associate Professor of Socio-Technical Algorithmics at the Faculty of Electrical Engineering, Mathematics and Computer Science (EEMCS). His research focuses on ways to help people make decisions in complex situations. As an academic he forms an important link between the team and the University.

What is the goal of the Autonomous Greenhouse Challenge?

“The population of the world is increasing and so there is a growing demand for high-quality food,” says Baart de la Faille. “Products grown in greenhouses meet this demand for quality, so many more greenhouses will be built around the world. This worldwide demand for greenhouses also poses a problem: it will become difficult to find properly trained personnel to manage the greenhouses and crops. Dutch greenhouse growers often go abroad to set up a new greenhouse business. Most of these growers are now in their 50s and 60s and will be retiring in ten years’ time, but there are not enough new growers to fill their shoes. The greenhouse challenge is a response to this problem. We want to give a boost to the development of autonomous greenhouses that are managed by artificial intelligence.”

How does the challenge work?

“The challenge comprises two rounds,” explains Baart de la Faille. “The first round involved a hackathon in which more than 200 people from all over the world took part in 21 teams. The participants in the hackathon had to grow tomatoes in a virtual environment and points were also awarded for the team composition and the team’s action plan. Five finalists were selected from the hackathon teams, including us, The Automatoes! We started growing real tomatoes in the greenhouse in Bleiswijk in December and the challenge ends in May. This is done completely remotely; the participants are not allowed to enter the greenhouse at all.”

Why are you taking part in the challenge?

“I have been working in this sector for a long time now,” says Baart de la Faille. “About five years ago I predicted that autonomous greenhouses would become a trend, and this fascinated me. When I applied for the position at Van der Hoeven I told them about the challenge. The director was immediately enthusiastic and we started looking for suitable partners to form a team. The company Hoogendoorn, which supplies climate computers, was keen to participate. I got in touch with TU Delft through the Delft AgTech Institute, where Tamás Keviczky and Neil Yorke-Smith soon became enthusiastic. Things started rolling pretty quickly after that and the team was expanded to include, among others, a number of TU Delft students and the company Keygene, a specialist in plant breeding.”

It’s important for us to be able to work at the interface between fundamental research and industry

“My work involves helping people to make decisions in complex situations, mainly with the use of algorithms,” says Yorke-Smith. “In my research group we are trying to understand fundamental concepts. We want to know why certain choices work in one situation and not in another. We think that our algorithms will prove useful in this Autonomous Greenhouse Challenge. We’ve never worked in this sector before, and so it’s also an opportunity for us to confront challenges and requirements that you do not usually find in other areas of our research.”

“It’s important for us to be able to work at the interface between fundamental research and industry,” he continues. “We have access to the latest algorithms for machine learning and we can put them to good use in the horticultural sector, but if the industry isn’t looking for this technology and is more concerned with other issues, then you won’t find a common ground.”

You performed well during the hackathon and are now among the finalists. What is your team’s strength and what added value does the knowledge of TU Delft bring?

“Looking back at last year’s challenge, we saw that most of the teams used a wide range of machine learning models to manage the greenhouse,” says Yorke-Smith. “Of course each model was different in the details, but broadly speaking they all did the same thing. For us, machine learning was not an end in itself, but a means for achieving our goal: to grow plants in a greenhouse under optimum conditions.”

The hardest part really is identifying what the problem is in the greenhouse and finding the right optimisation algorithm to remedy it

“This doesn’t necessarily mean only using machine learning technology,” he continues. “We also made extensive use of model-based AI and data-based optimisation processes. We first try to gain a thorough understanding of the system and then we start adding intelligence where it’s needed to make the system do what we want it to do, as opposed to simply controlling the system like a black box.”

“The hardest part really is identifying what the problem is in the greenhouse and finding the right optimisation algorithm to remedy it,” Baart de la Faille adds. “To do that, you need to have access to knowledge in various fields; you need to know how optimisation works and how a greenhouse functions, but you also need knowledge of plants. Thanks to the variety of backgrounds and knowledge of our team members, we have that combination. Working together with other disciplines results in synergies. This challenge is a good example of how we can combine our strengths.”

The competition is currently in full swing. How is it going so far?

“We started work in our section of the greenhouse in mid-December,” says Baart de la Faille. “After almost two months, the first tomatoes have been harvested and this will now be part of a regular cycle. In principle, the computer manages the greenhouse based on our own algorithm and the data we receive from the sensors, the so-called setpoints. We still conduct quite a lot of analyses ourselves to see what’s happening and check whether the system is responding properly. And all this without entering the greenhouse.”

“We are wary about modifying our algorithm,” continues Yorke-Smith. “Plants go through different stages during the growth process. If we make an adjustment and the plant shows improved growth, we can’t say with certainty whether it’s because we changed our algorithm or because it was very sunny that week.”

“This challenge also has a competitive element,” says Baart De la Faille. “It’s about which team makes the most profit. The costs involve electricity consumption, water and labour, among other things, and the turnover depends on how much money the tomatoes make us. The price we get on paper for the tomatoes depends on changes in the sugar content over time. Tomatoes are worth much more in January than in summer. The team that makes the most profit, uses the least energy and raw materials and has best methodology and approach will be declared the winner of the Autonomous Greenhouse Challenge in May.”