SUSTAINair focuses on circular aviation for green transition

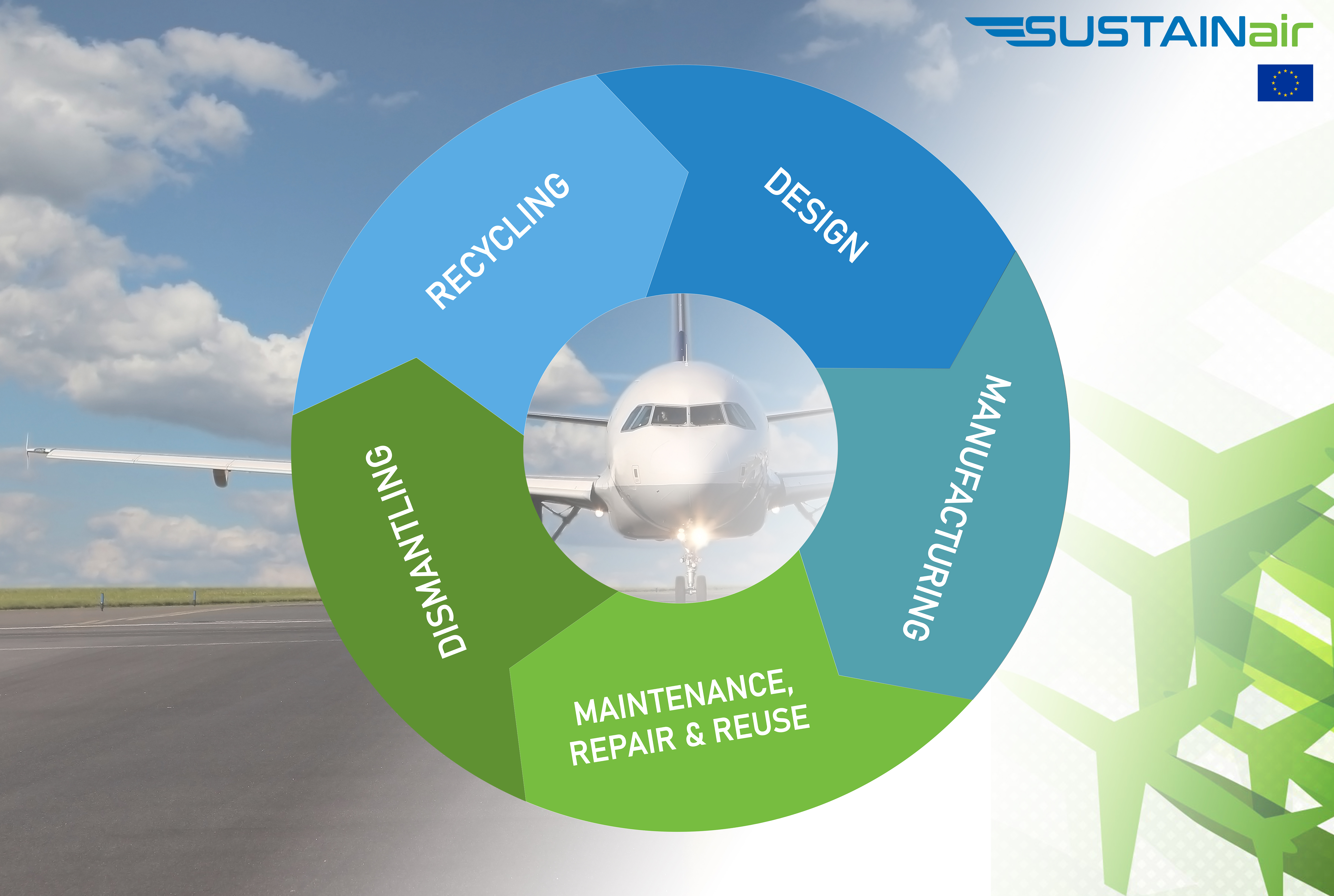

Horizon 2020 project SUSTAINair was launched recently to research and develop solutions to increase resource efficiency and aircraft performance while cutting down on waste and material costs throughout the aircraft life cycle, what is known as circular aviation.

This EU-funded research aims to make the entire aviation supply chain ecosystem greener in line with the Circular Economy Action Plan, setting new standards for aerospace manufacturing enabling an increase in cross-sector synergies. Based on the circular economy approach, SUSTAINair provides the aviation sector with a runway to a more cost-effective, low-carbon economy while tackling the increase in resource consumption, waste and emissions.

Chiara Bisagni, Professor in Aerospace Structures and AIAA Fellow is partner in the project for Delft University of Technology, The Netherlands.

Novel aerospace structures to reduce weight, CO2 emissions

Minor changes to the materials or to the aircraft structure can have major results when it comes to fuel consumption. Novel metal alloys and composite materials, such as carbon fibre reinforced polymers, are used to reduce mass and increase aerodynamic efficiency, thus improving fuel consumption during flight operations, and therefore reducing emissions.

With that in mind, SUSTAINair will develop not only novel materials for a flexible wing, but also techniques for the integration of sensors in the material used in such aircraft components. For example, the monitoring of real-time data allows the operators to adjust the flightpath of an airplane resulting in lower fuel consumption, while increasing the safety and the reliability of aero-structures, as well as reducing maintenance costs.

Such a combination of metal and composite materials does not come without technological challenges to joining and repair operations, as well as for circular approaches in the end-of-life process. “What is unique about SUSTAINair is that the design process will be formed to allow for innovative techniques along the value chain which will give the material a longer life with more value, accounting for end-of-life disassembly and upcycling,” said Prof. Chiara Bisagni, TU Delft.

Reducing waste

The novel up- and recycling methods developed within SUSTAINair for both metal and composite aviation materials, will contribute to a major reduction of waste incurred during the manufacturing and end-of-life processes. The project aims to develop near net-shape components (manufactured as close to the size and the shape of the finished product) for the aviation industry thus reducing material wastage.

Aircraft consist of many parts from various materials that need to be joined. Currently the joining is done by using rivets, which are difficult to remove and heavy. This makes the separation, and thus efficient recycling, of aircraft components challenging and costly to the point of being not economically viable. The SUSTAINair project will develop a robot head that automatically detects and removes rivets, allowing for alloy separation and hence higher value recycled aircraft material. The particular expertise of project partners in welding and in other joining techniques could ultimately eliminate the need for rivets.

Green transition path to recovery aviation industry

The COVID-19 crisis has plunged the sector into uncertainty with many aircraft being taken out of service earlier than anticipated. Despite that, boosting the post-pandemic aviation industry´s green transition remains a strategic objective of governments providing a path to recovery. The technological innovations brought about by the transition to a circular economy can be seen as a pathway for tackling the economic effects of the Covid-19 pandemic in industries along the entire aviation component supply chain.

European collaboration

Starting in January 2021 and spanning a period of 3.5 years with a budget of €5 million, the SUSTAINair project is a collaboration of 11 European research organisations and industrial partners. Jürgen Roither, research engineer at the Center for Low-Emission Transport at the Austrian Institute of Technology AIT-LKR, Austria's largest research and technology organization coordinates the project: “SUSTAINair is addressing all phases of the aircraft component value chain from circular design to manufacturing, maintenance and repair, to assembly and recycling, and it will excel through the combined competence and expertise of its project partners”. The project partners are on the forefront of circular aviation pursuing objectives set by the EU Green Deal and Flightpath 2050.

The partners of the project are: AIT-LKR Leichtmetallkompetenzzentrum Ranshofen GmbH (Austria), Netherlands Aerospace Centre – NLR (Netherlands), Deutsches Zentrum für Luft- und Raumfahrt e.V. – DLR (Germany), JOANNEUM RESEARCH (Austria), Johannes Kepler University Linz (Austria), Delft University of Technology (Netherlands), AEROCIRCULAR (Belgium), INOCON Technologie GmbH (Austria), INVENT GmbH (Germany), Dutch Thermoplastic Components B.V. (Netherlands), RTDS Association (Austria)

See the project website for additional information: http://www.sustainair.eu and read the full press release here.