4D Total Fatigue

Currently, fatigue design of welded ship and offshore structures is predominantly based on test results from uniaxial and constant amplitude fatigue tests. In other words, the fatigue lifetime estimation methods that are used are often phenomenological in nature. To determine a fatigue lifetime estimate under (non-proportional) variable amplitude loading, such methods (based on uniaxial fatigue data) are used in combination with cycle counting and a damage accumulation hypothesis. However, when welded joints are subjected to multiaxial stress states, the fatigue lifetime estimates that are obtained with such an approach can be non-conservative, especially when stress components vary non-proportionally in time (Sonsino, 2008). With the intention to improve the accuracy of fatigue lifetime estimates under multiaxial stress states, numerous multiaxial fatigue assessment methods have been developed. However, they often have limited applicability and compatibility due to their complexity, lacking experimental validation and non-scalability of the phenomenon of fatigue in welded joints.

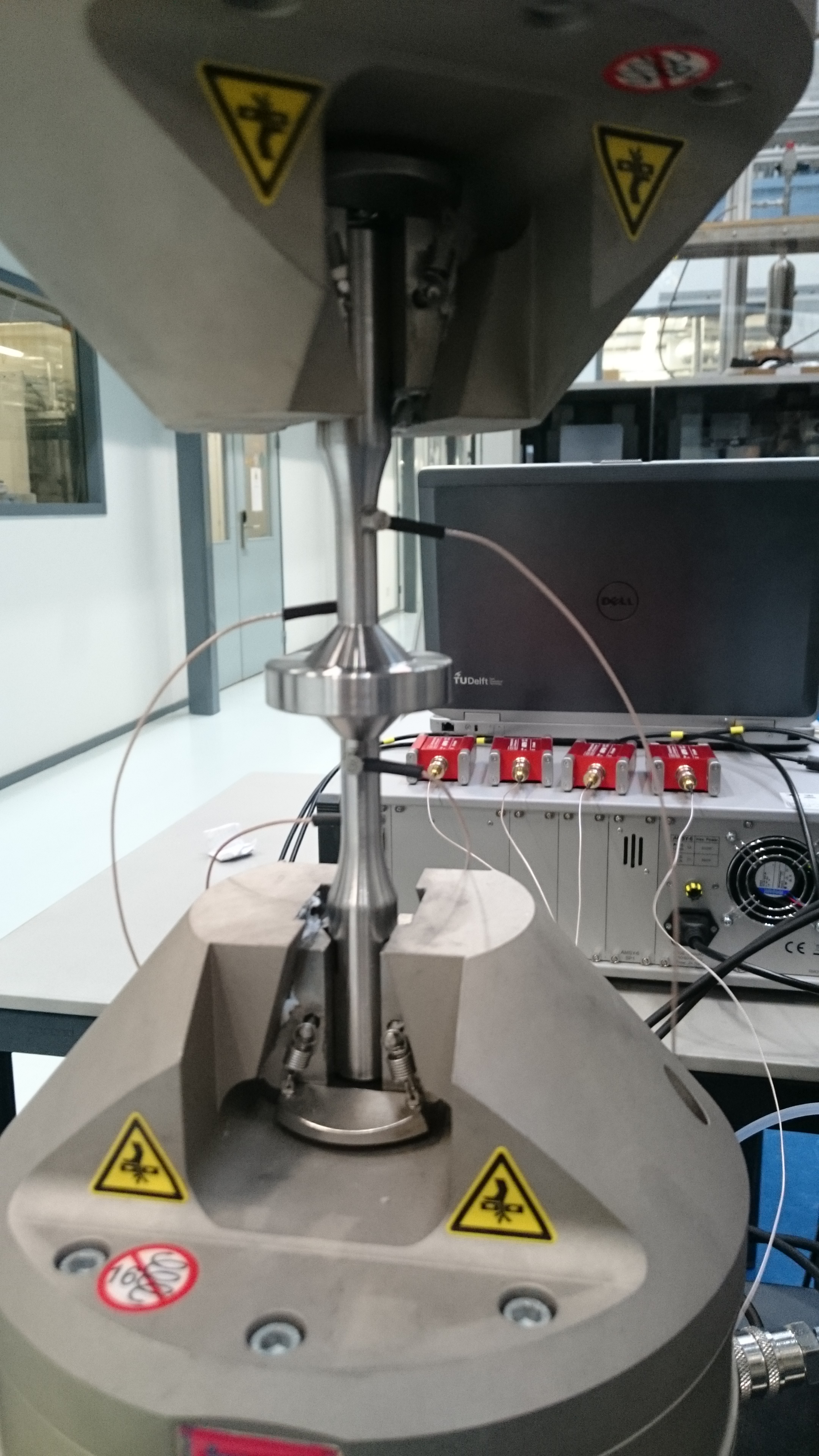

This research focuses on the phenomenon of multiaxial fatigue in welded structural details. For this purpose, three scopes of work are executed in parallel: a numerical scope of work, a fundamental scope of work and an experimental scope of work. The numerical scope of work aims to identify locations in marine structures where multiaxiallity occurs. This is relevant to justify the project initiative to the industrial partners but it also provides insights in where and when the multiaxiallity is geometry or loading induced. The fundamental scope of work beholds investigation and interpretation of the state-of-the-art multiaxial fatigue methods. A multiaxial test facility will be built so that fatigue resistance of a welded structural detail can be experimentally determined under different (loading) conditions. Finally, from comparison between analytical fatigue lifetime estimates and experimental data, a most adequate method can be identified (or potentially developed).

The objective of this research is to identify a unified method for the assessment of multiaxial fatigue in welded joints under non-proportional, variable amplitude loading. With this method it will be possible to make more accurate lifetime estimations then current practice. This will contribute to the optimization of maintenance and repair strategies. Furthermore, a simplified method for engineering practice could potentially be developed.

The research has received substantial Dutch subsidy which is co-founded by ten sponsors varying from offshore operators, oil & gas companies, shipyards, class societies and governmental institutions. In addition several companies have already joined, or are in the process of joining, as Joint Industry Participant. The research will run from 1st July 2019 – 31st December 2020.