Fatigue strength and life time characteristics of friction stir welded joints in steel maritime structures

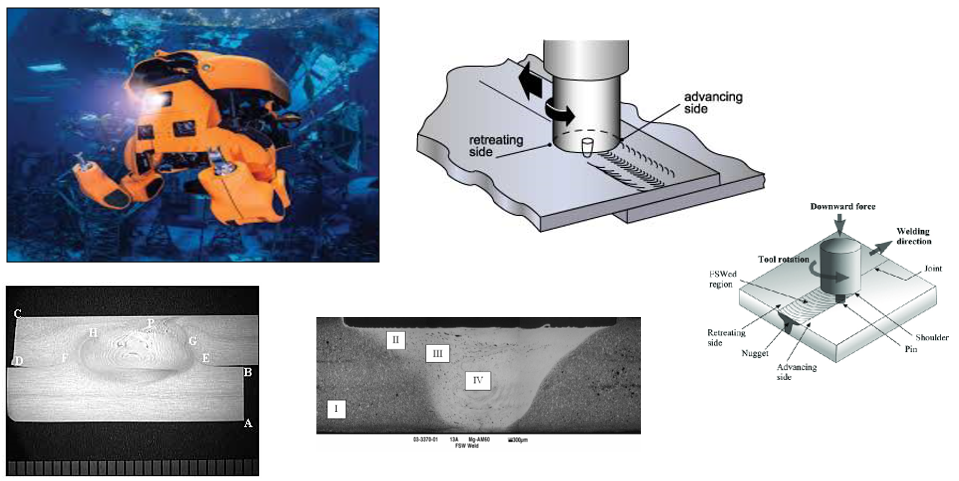

Aiming for high-quality joints connecting structural members of steel maritime structures, Friction Stir Welding (FSW) is shown to be a promising technology for manufacturing as well as (underwater) weld repairs. However, because of the short FSW tool service life, the costs are high, meaning the competition with conventional arc-welding is typically a battle lost in advance. In order to introduce low-cost FSW systems to the maritime industry, new FSW tools will be developed in the H2020 RESURGAM project (link at bottom of this page). The welded joint ultimate and fatigue strength performance has to be verified and optimum welding parameters have to be established.

Strength assessment models for arc welds are not one-to-one applicable for FSWs. The static joint strength of arc welds is typically low in comparison to base material values. The arc-welded joint geometry contains severe notches, introducing stress concentrations (fatigue sensitive locations) in typical loading & response conditions. The crack growth contribution to the total fatigue life time is governing. For FSW joints, on the other hand, the static strength is typically high in comparison to base material values. Only mild notches are introduced, meaning the crack initiation contribution to the total fatigue life time has to be accounted for, as reflected in parameters like characteristic defect size, volume effects, surface roughness and undercut.

Since fatigue is a governing limit state for maritime structures, the main goal is to establish a FSW characteristic fatigue strength criterion. Main objectives in this respect, are: (i) to relate static strength and fatigue strength properties of FSW joints, (ii) to capture initiation and growth contributions to the total fatigue lifetime, (iii) to characterize multi-scale short- and long-crack growth development, (iv) to connect micro- and meso-material to macro-structural properties and (v) to establish small scale (material) and large scale (structural) fatigue resistance similarity.

Link to project website: