Theme 1: Dynamics of Material and Equipment Interaction

Theme focus

We aim to design more efficient and sustainable machinery and multi-machine systems for handling goods (dry bulk, powders, containers, break bulk, etc.) with less energy consumption, less maintenance costs and less environmental pressure. It is our expertise to understand, analyse and model the interaction between the goods, the operational conditions and the machines in order to be able to optimize model-based designs. This dynamical interaction is crucial for analysis, predictive modelling and predictive design of machinery such as cranes, belt conveyors, grabs, and robots. But also for the design of drive and energy systems that power the machinery.

Subfields

Three specific fields are distinguished within this research theme: 1. Analysis, Design and Optimization of handling systems and 2. Analysis, Design and Optimization of structures, 3. Analysis, Design and Optimization of Drive and Energy Systems.

1. Analysis, Design and Optimization of Handling Systems

Handling of solid goods includes granular materials, containers and break bulk. We focus on designing the equipment in interaction with cargo on the one hand and logistics system on the other hand.

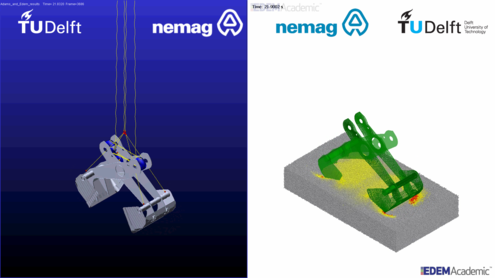

Particulate solids vary from fine powders to raw materials with big lumps and are present in many transport and production processes from grains and seeds in the food industry to iron ore for steel production. The behaviour of particulate systems is complicated and difficult to describe analytically, especially when the material interacts with machinery under various operational and environmental conditions. Discrete Element Method (DEM) can capture the complexity and improve the process or machine design with virtual prototyping. With upcoming materials such as energy carriers in solids form, it is of crucial importance to understand the material behavioural characteristics in order to design optimal handlings systems in terms of efficiency, and the required infrastructure on logistics level.

Container handling is becoming more autonomous and different concepts of ports of the future are being developed where more agile equipment is necessary to be designed. This new generation of equipment has to adapt to different quay conditions, different level of autonomy and operators to provide optimal logistics at terminals. Even the potential of floating solutions is explored for increasing efficiency of ports. The design of such complex equipment requires system level design with integrating structure design, autonomy and logistics concept at all times.

Break bulk or general cargo, refers to goods that are stowed on board ship in individually counted units, such as steel coils and turbine blades. The handling of these units is still done in a very traditional way, leading to long handling times as well as very labour-intensive and high-risk tasks. Introducing soft robot solutions may improve the safety and efficiency of handling uniquely shaped objects. Design of large-scale soft robots requires innovative approaches in the use of compliance and smart materials. Nonlinear mechanics modelling is necessary to capture flexibility, actuation and large deformations of soft robots.

Research challenges include:

- For emerging materials such as new (solid) energy carriers, deep sea nodules, and changing properties as a result of excavation of minerals below groundwater levels the focus should not only be on chemical properties but also on the physicochemical properties describing the material behaviour characteristics for handling and design of equipment and infrastructure integrally.

- How to account for handling and machine cargo interaction characteristics while designing equipment?

- How will (origins of) materials, new technologies, concepts and (origins of) materials impact handling, transport and infrastructure?

- Machines, especially autonomous machines, have to learn their environment and cargo and adapt to it to successfully complete a task. How to design adaptive machines that can continuously reconfigure to optimally serve the handled goods in varying operational conditions?

2. Analysis, Design and Optimization of Structures

Structures are the core of every mechanical system and optimal design can increase sustainability, efficiency and reliability of the machine. As the machines are becoming more agile, more autonomous and more connected, they need to adapt to their environment and operational conditions.

To enhance the adaptability of transport machines for goods handling we explore metastructures with tailored properties for shape morphing, wear reduction or energy absorption. Parametric and generative design as well as machine-learning techniques are applied for design exploration and optimization. Topology optimization and shape optimization approaches are integrated with nonlinear behaviour of structures. Uncovering the potential of smart materials into the design of adaptive machines requires understanding the scaling up effects from property side as well as from functionality perspective. The developments in the additive manufacturing domain can support the applicability of tailorable properties in large-scale structures.

For the structural analysis of transportation equipment we use Finite Element Method (FEA) and Multi Body Dynamics (MBD). When coupled, they are used to study the influences of the different loads by checking a number of design criteria such as: stress levels, deformations, buckling, eigen frequencies and fatigue.

Research challenges include:

- Emerging technologies such as additive manufacturing, machine learning, virtual reality, industry 4.0/5.0 have the potential for disruptive innovations. How to utilize the benefits of emerging technologies in large-scale structures design?

- Smart materials, materials responsive to external stimuli, have shown unique properties in terms of shape-morphing, self-actuation and energy harvesting. How to integrate smart materials in large-scale (metamaterial) structures design?

3. Analysis, Design and Optimization of Drive and Energy Systems

Many mechanical systems need to be driven. Because of energy transition (the transition from fossil fuels to renewable energy), there is a lot of innovation in drive and energy systems. Energy efficiency is increasingly important, and often large energy savings are possible by properly analysing energy systems. Electrification is a trend in all kinds of drive and energy systems because renewable sources mostly generate energy in an electric form. For systems that cannot be connected to the electric power system, energy storage is required. In some applications, batteries are a good solution. In other applications, such as ships and airplanes, a transition towards renewable fuels is necessary.

The research focuses on the analysis, design and optimisation of these drive and energy systems. Research challenges include the following aspects.

- There is a large variety of possible drive and energy system architectures, with a variety of energy storage systems and energy conversion methods. Energy storage systems include fuel tanks, hydrogen storage, and batteries. Energy conversion methods include combustion engines, fuel cells, electrical machines and power electronic converters. How can we optimally select and size these components?

- The transient performance of these systems may be very different from the tradition combustion engines and is far more complicated because of the larger number of components. How to control the transient performance?

- The control of these drive and energy systems can have a large impact on the degradation and the lifetime of components such as fuel cells and batteries. How to control these drive and energy systems while minimizing degradation of these components?

Projects

- Tidal Turbine Power Take-off Accelerator -TIPA

- Design optimization and prototyping of large-scale metamaterial structures for vibration control

- Simulation of Flow and Packing behavior of Multi-Component Particle Mixtures

- DEM simulation of grabs and cohesive materials

- Metamodelling of the behaviour of bulk and granular material handling equipment

- Torrefied biomass pellets: Product of the future, logistics of today?

- Space@Sea – Transport and logistics hub

- Discrete Element Modelling to enable optimal blast furnace Charging (DEM-OC)

- Toward Smart Grabs

Finished projects

- Dutch Biomass infrastructure (BiologikNL)

- Sustainable Deep Sea Mining Transport Plan

- Grab of the Future: Virtual prototyping of grabs using Discrete Element Modeling

- Modelling dust liberation by Discrete Element Method and Computational Fluid Dynamics

- Wear reduction of transportation equipment using Bionic Design and Discrete Element Method

- Dynamics and Swing Control for Grab Ship Unloader

- Design of a Large-Scale Bulk Terminal for Biomass

- Large-scale Homogenization of Bulk Materials in Mammoth Silos

- Spillage prevention in bulk handling

Facilities

Research groups

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/7/1/csm_impactless-material-handling-naam_2ba3370ac2.jpg)