Grab of the Future: Virtual prototyping of grabs using Discrete Element Modeling

Research of Stef Lommen

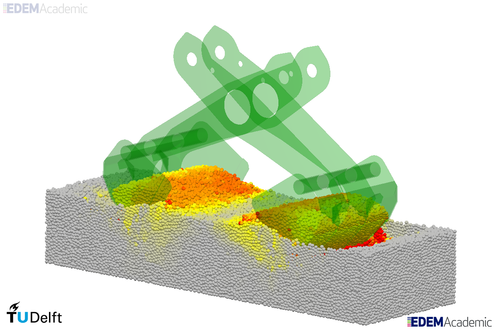

Grabs are a type of bulk handling equipment used for the transfer of bulk solids such as iron ore from vessel to shore. Traditional design of bulk handling equipment involves high costs and long development periods. An affordable way of evaluating and optimizing designs of bulk handling equipment could be realised with virtual prototyping and the help of simulations. The Discrete Element Method (DEM) is a discrete simulation technique which simulates individual particles resulting in a simulation of the bulk material. Although the method has been proven to work in idealized lab experiments, the validation of industrial application is underexplored. This research aims at the DEM modeling of iron ore and grab interaction, enabling virtual prototyping of grabs and other bulk handling equipment. An important aspect of this research is the validation of industrial application of DEM.

Background and problem definition

Bulk handling equipment used on bulk terminals and in mines has been around for many years. The current design process of bulk handling equipment involves high costs, long development periods and high risks. Due to the particular nature of bulk material, modeling of bulk material with a continuum approach is difficult. Especially for equipment types such as grabs where interaction between bulk material and the equipment influences the performance heavily.

With the increase in computational power nowadays it has become feasible to use a discrete approach such as the Discrete Element Method (DEM). By modeling particles individually, DEM simulates the behavior of all particles, resulting in a simulation of the behavior of the bulk material. Force propagation, particle flow and interaction with the equipment can all be retrieved from a DEM simulation, providing insight in the particle processes during the handling of the bulk material.

Goal

The aim of this research is to simulate bulk material with the use of the Discrete Element Method (DEM), coupled with MultiBody Dynamics (MBD) simulations of grabs. With these simulations it will be possible to evaluate current designs and predicting the increase in performance of designs improvements. In the end, this could result in an affordable way of innovating bulk handling equipment.

Approach

As with every numerical simulation, reliability of the results is extremely important. Without a proper validation of the simulation the results produced may render useless. The first part of this research focuses on validation of the simulations; both virtual particles and virtual grab operation. This is done by characterizing iron ore through experiments and modeling the virtual material and its interaction in such a way it represents iron ore. When simulations have proven to be accurate the research will continue investigating the interaction between bulk material and the equipment handling it.

Funding

This research is supported by grab manufacturer Nemag b.v, the Netherlands. Their support is gratefully acknowledged.

Contact

PhD Candidate: ir. S.W. Lommen

Thesis supervisor: Prof.dr.ir. G. Lodewijks

Daily supervisor: Dr.ir. D.L. Schott