Team Dey

Our research focusses on computation-guided design of materials for sustainable and renewable energy application. Hydrogen is one of the most potential candidates for sustainable energy storage that is produced in an eco-friendly manner. The research activities of our group are focused on (i) the identification and optimization of materials for efficient hydrogen storage based on multi-scale approach combining quantum mechanical Density Functional Theory (DFT) calculations with Molecular Dynamics simulations (ii) DFT based materials designing e.g. steels to make them better resistant to Hydrogen Embrittlement.

Our second research line is dedicated to another promising route for sustainable energy production, via usage of thermoelectric devices. There is an ongoing quest for materials that are capable of converting huge amounts of available waste heat into valuable electrical energy. The research interest of our group lies in using DFT for identifying and tailoring material properties for improved energy conversion efficiency of thermoelectric materials.

Research

Multi-scale modeling of hydrogen effects on materials

Hydrogen (H2) will be an increasingly important fuel in the future green economy. It is an ideal green fuel because it is renewable, lightweight, nontoxic in nature, and available in enormous amounts. Known bottlenecks in the efficient large-scale realization of H2-based technologies are the control over the production, storage and release, as well as the safe transportation of H2. To establish a viable ‘H2-based economy’, it is crucial to design materials with properties that allow overcoming these bottlenecks. For instance, the materials for H2 storage applications should fulfill various requirements such as low weight, robustness (i.e. prevent hydrogen embrittlement), being easily synthesizable and have a low cost. Such materials should have rapid adsorption and desorption kinetics in order to act as reversible H2 storage media.

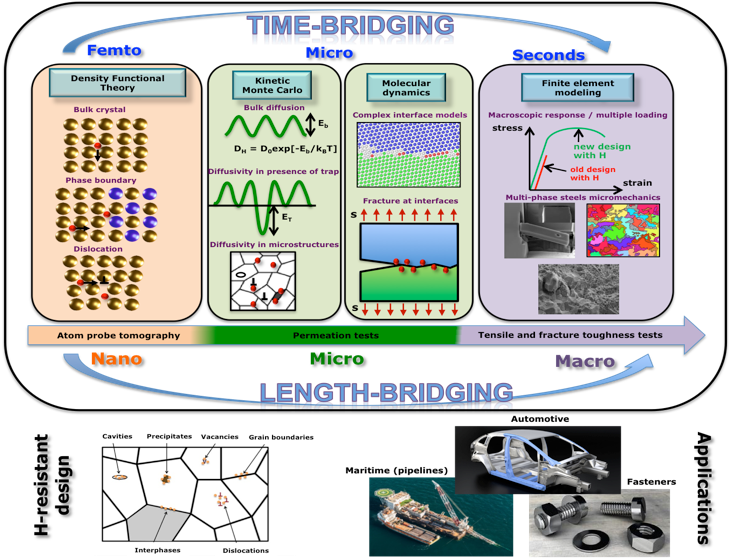

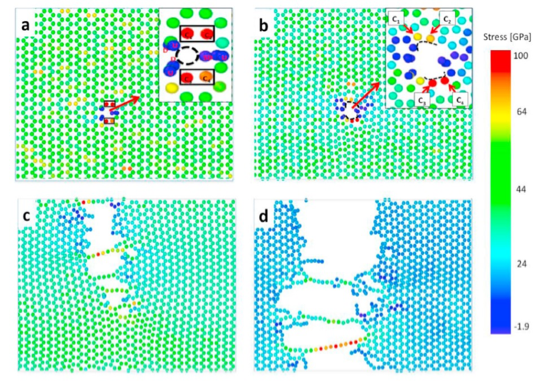

One of our research interests lies in understanding hydrogen interaction with microstructural features at atomistic level in order to make materials, e.g. steels, better resistant to hydrogen embrittlement (HE). Within the framework of our NWO funded project, we are collaborating with Dr. Vera Popovich (MSE department, TU Delft) and Dr. Francesco Maresca (University of Groningen) to obtain deeper insights into the underlying mechanisms of HE. The underlying approach of the project is based on multi-scale modelling-experimentation synergy based on Density Functional Theory, Molecular Dynamics, Crystal Plasticity and advanced experimental characterization that will connect atomistic information with the microstructural behaviour of multi-phase steels in presence of hydrogen, enabling design of new steels that are resistant to HE (Fig. 1). The novel methodology developed within the project for steels, will be transferrable to other technologically relevant materials e.g. superalloys and the novel high-entropy alloys. Our research interest also lies in the identification and optimization of materials for efficient H2 storage based on multi-scale approach combining quantum mechanical Density Functional Theory (DFT) calculations on phase stability with Molecular Dynamics (MD) simulations on atomistic kinetics. Together with our colleagues from P&E department of TU Delft, Dr. Othon Moultos and Prof. Thijs Vlugt, we are investigating the hydrogen storage efficiency of two-dimensional materials such as boron-based materials and graphene (Fig. 2).

Tailoring material properties to design thermoelectric materials with improved performance

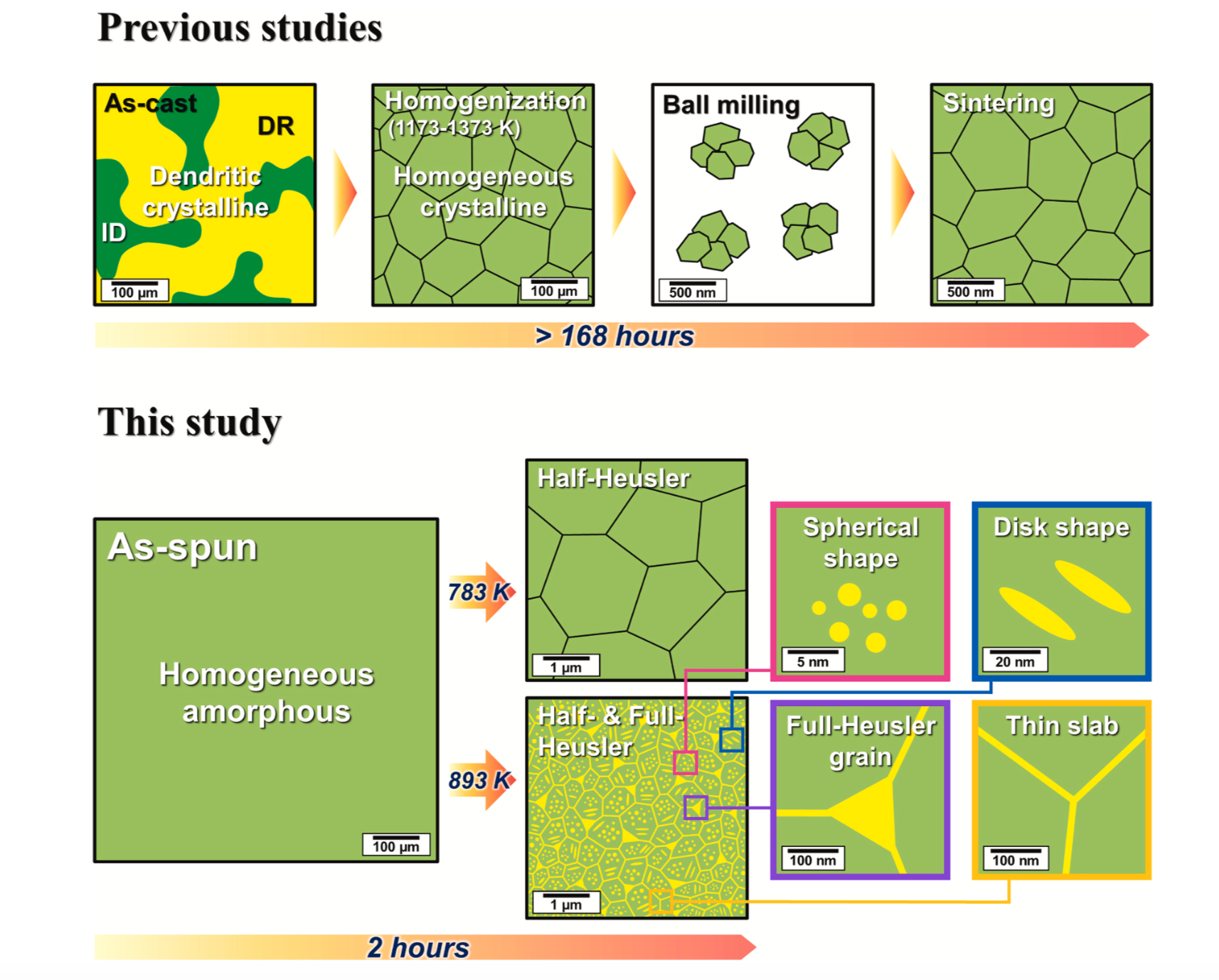

Thermoelectric energy generation technology has opened up a potential route for the efficient conversion of waste heat into valuable electrical energy. Given the huge amounts of heat energy wasted by industry - one estimate suggests up to 68% - there is huge potential for large-scale thermoelectric power generation. Higher energy conversion efficiency can be achieved by maximizing the ratio of electrical and thermal conductivity for thermoelectric materials with a high Seebeck coefficient. The intercoupling feature of the physical parameters, i.e. Seebeck coefficient, electrical and thermal conductivity, however makes it a long-lasting challenge to obtain high-energy conversion efficiency. My research activities focus on computation-based designing of thermoelectric materials with optimized performance. One of the materials of my interest is the half-Heusler alloy. These alloys have attracted enormous attention because of their desirable properties such as good values of the thermoelectric figure of merit, robust mechanical properties, high-temperature stability, low cost and usage of non-toxic and earth-abundant elements. I, together with my collaborators from Korea Advanced Institute of Science and Technology (South Korea), proposed a novel approach to fabricating thermoelectric material with nanostructures to increase energy conversion efficiency (Fig. 3).

Highlighted publications

- P. Habibi, T. Saji, T. J. H. Vlugt, O. A. Moultos, P. Dey, Hydrogen Dissociation in Li-Decorated Borophene and Borophene Hydride: An Ab-Initio Study, Applied Surface Science 603, 154323 (2022).

- Y. Ji, N. Li, Z. Cheng, X. Fu, M. Ao, M. Li, X. Sun, T. Chowwanonthapunya, D. Zhang, K. Xiao, J. Ren, P. Dey, X. Li, C. Dong, Random forest incorporating ab-initio calculations for corrosion rate prediction with small sample Al alloys data, npj Materials Degradation 6, 83 (2022).

- L. Sreekala, P. Dey, T. Hickel, J. Neugebauer, Unveiling nonmonotonic chemical trends in the solubility of H in complex Fe-Cr-Mn carbides by means of ab initio based approaches, Physical Review Materials 6, 014403 (2022).

- P. Habibi, T. J. H. Vlugt, P. Dey, O. A. Moultos, Reversible Hydrogen Storage in Metal-Decorated Honeycomb Borophene Oxide, ACS Applied Materials and Interfaces 13, 43233 (2021).

- P. Habibi, A. Rahbari, S. Blazquez, C. Vega, P. Dey, T. J. H. Vlugt, O. A. Moultos, A New Force Field for OH− for Computing Thermodynamic and Transport Properties of H2 and O2 in Aqueous NaOH and KOH Solutions, The Journal of Physical Chemistry B 126, 45, 9376 (2022).

- G. K. Sunnardianto, G. Bokas, A. Hussein, C. Walters, O. A. Moultos, P. Dey, Efficient Hydrogen Storage in Defective Graphene and its Mechanical Stability: A Combined Density Functional Theory and Molecular Dynamics Simulation Study, International Journal of Hydrogen Energy 46, 5485 (2021).

- A. Hussein, A. H. M. Krom, P. Dey, G. K. Sunnardianto, O. A. Moultos, C. Walters, The effect of hydrogen content and yield strength on the distribution of hydrogen in steel: a diffusion coupled micromechanical FEM Study, Acta Materialia 209, 116799 (2021).

- C. Jung, B. Dutta, P. Dey, S. Jeon, S. Han, H. Lee, J. Park, S. Yi, P. Choi, Tailoring nanostructured NbCoSn-based thermoelectric materials via crystallization of an amorphous precursor, Nano Energy 80, 105518 (2021).

- P. Dey and B. Dutta, Decisive role of interstitial defects in half-Heusler semiconductors: An ab initio study, Physical Review Materials 5, 035407 (2021).

Projects

Ongoing:

- Designing hydrogen-resistant alloys through novel multi-scale modeling and experimentation (De-Hy) funded within NWO Materialen NL: Challenges 2018 grant

- State-of-the-art multi-scale simulations and artificial intelligence to identify nano-porous materials for efficient hydrogen storage funded within ME Cohesion 2020 grant

- Data-Driven Search for New High-Entropy Alloys for Engineering Application funded within ME Cohesion 2022 grant

- Efficient and sustainable production of hydrogen based on atomistic study and machine learning funded by MSE department

Past:

-

Towards light and eco-friendly steels: Multi-scale modeling of hydrogen embrittlement funded within ME Cohesion 2019 grant

Industrial partners

Tata Steel, Allseas Engineering, Koninklijke Nedschroef Holding, Daimler