Max-SCORE: Maximizing SCrap in COnverter REfinging

Shifting the limits of scrap usage in steelmaking converters to minimize CO2 emissions

The HIsarna process is a new and breakthrough smelting reduction technology for the production of liquid hot metal from iron ores and coal. The main driver to develop this process was the need for a totally new ironmaking process with a significantly reduced carbon footprint and it was an outcome of the large EU framework project “ULCOS” (Ultra Low CO2 Steel Making). Since 2010 a pilot plant has been operational at the Tata Steel site in IJmuiden, the Netherlands. During the previous campaigns it was demonstrated that the HIsarna process has a very high raw materials flexibility with very little raw materials pre-processing, and no coking or agglomeration is required. During the HIsarna pilot campaigns it has also revealed that it was possible to concentrate the Zn from secondary raw materials such as flue dusts from ironmaking and steelmaking plants into the HIsarna process dust. The availability of primary zinc ores and concentrates is reducing, driving up prices for the ores and concentrates. Therefore there is an increased interest from zinc industry in acquiring suitable secondary resources of Zn concentrates.

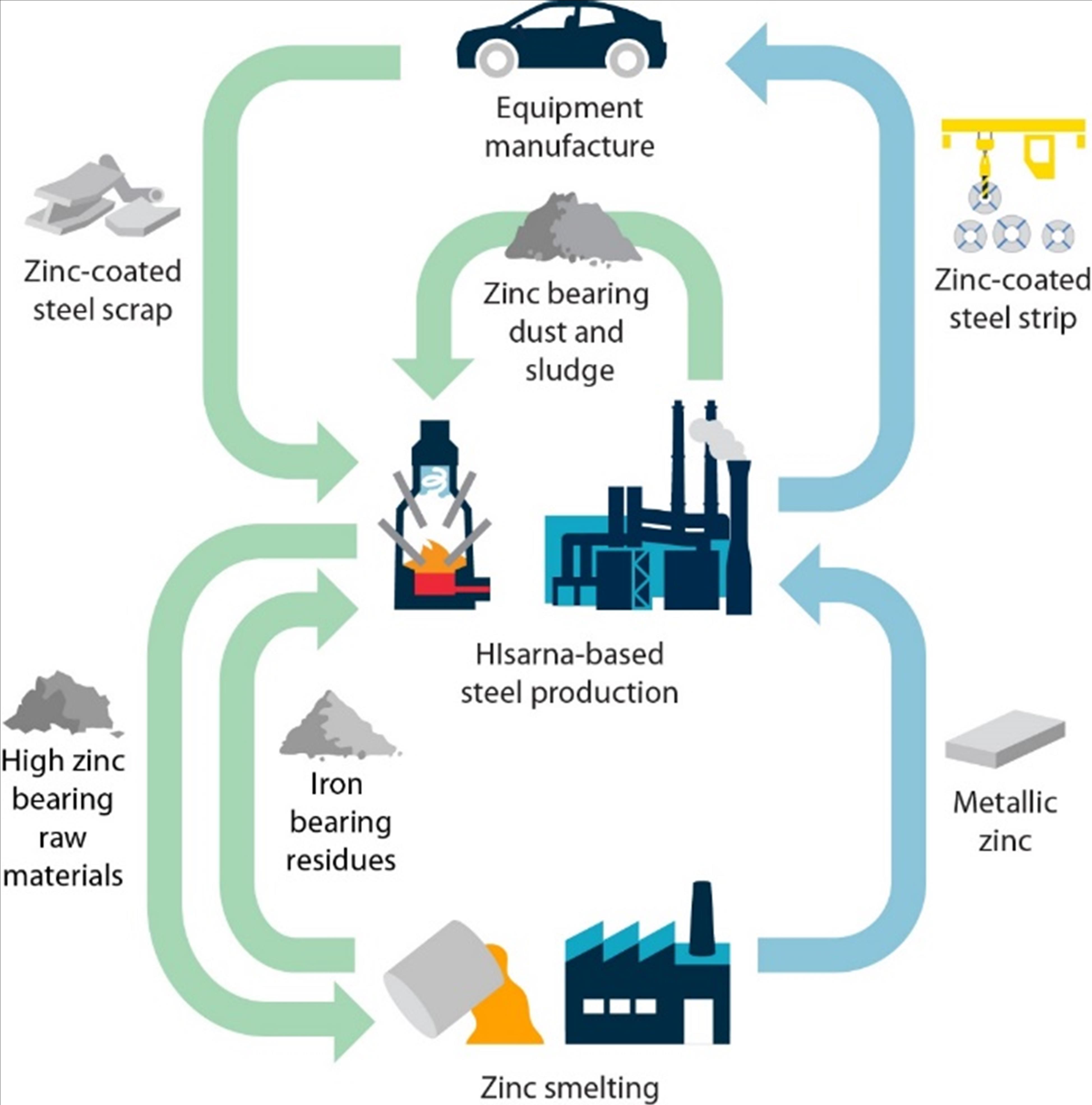

The ultimate goal of the ReclaMet project is to achieve an enrichment level on Zn in the process dust of HIsarna which would make it suitable for direct use in Zn smelting. Extraction of zinc from HIsarna dust and reusing it for zinc production will significantly reduce the environmental impact and contributes to a circular economy of raw materials industry.

The project is coordinated by Tata Steel R&D in IJmuiden, in partnership with TU Delft, CRM Group in Liege, and Nyrstar Budel Zinc. The ReclaMet project runs for 3 years (started in April 2018) with one year extension till end of 2022, and has a total funding of 5 M€ for a period of 3 years. TU Delft has a share of 1.2 M€ for one PhD student and 2 postdoc researchers within MPRR, focusing on Maximising Zn enrichment in HIsarna process dust (WP2), preparing raw materials for pneumatic injection into the HIsarna process (WP3), Process models for development and improvement of process (WP4) and support process scale-up (WP5).