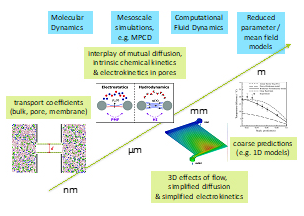

The goal of the Complex Fluid Processing group is to understand the complex interplay between transport processes and transformations on the mesoscale, and to apply this understanding to enable and improve fluid processing equipment.

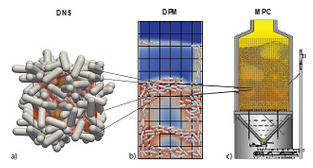

The mesoscale is defined as the scale of 0.1 micrometer to a few millimeter. This is the scale where most process limitations occur, i.e. where different transport mechanisms, such as flow, diffusion, migration, and mixing, are competing with each other, and are possibly also competing with transformations, such as chemical reactions, phase change, and aggregation. By accurately modelling this interplay, we are able to improve equipment for the processing of particles, liquids, gases, multi-phase fluids and non-Newtonian fluids.

The current focus of our group is on improving equipment for processing of non-spherical particles (e.g. for biomass gasification in fluidized beds), non-Newtonian droplets (e.g. for spray-drying of complex dispersions such as milk), and fluids in porous media (e.g. for electrochemical conversion of CO2 using porous electrodes and catalyst layers).