Local Corrosion and Electrochemistry

Local electrochemical analysis of corrosion mechanisms

CTE has an outstanding academic track record on gaining detailed insight in the relation between microstructure, surface properties and (local) corrosion performance. The main, but not limited to, materials of interest are aluminium alloys, galvanized and high strength steel. Welding, chemical and thermomechanical treatments result in a strong change in the surface microstructure of the alloys. These changes in the microstructure are also reflected in the local corrosion behaviour of these alloys.

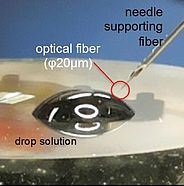

The scientific field of corrosion technology and electrochemistry is experiencing a scientific revolution due to the development of local probe techniques, which enables the study of the relation between microstructure and corrosion properties at the micron and submicron scale. While the historic development of corrosion science started with a simple deterministic and thermodynamic local approach of the phenomena observed, ironically the theoretical quantitative back-up of the phenomena did become possible only after the development of the mixed potential theory, which included the kinetics, but did average out the current density over the full surface area of samples, rendering quantitative interpretation of real local phenomena as pitting, galvanic corrosion etc, virtually impossible. The local probe techniques do combine the best of both worlds: local information including the kinetics.

While fundamental local electrochemical research on the microscale has become reality as since the last decade and will remain of major interest for the next many years to come, we envisage further developments towards downscaling of the area of research in the nanometer range. For systems that operate at this nanoscale, such as electronic devices, MEMS and NEMS, this need is obvious. For larger systems, corrosion at the nanoscale is involved in at least two key issues:- Corrosion prevention must include means to prevent the initiation of corrosion, and corrosion initiation takes place at the nanoscale.- The size of surface defects susceptible to trigger localized corrosion decreases as the design life-time of (high-purity) metal-based structures increases. Defects of nanometric dimensions become more important.