Microstructures

Metal alloys, be it based on iron, aluminium, magnesium or titanium matrix, owe their properties and performance to the assembly of phases and defects that we call the microstructure. Thermodynamic characteristics and kinetic processes on the nano- and micro-scale control the formation of the microstructure during thermomechanical treatment. The physical background of phase transformations and precipitation is studied experimentally and theoretically. Main themes in this research are the development of high-strength steel and aluminium alloys and the substitution of potentially scarce elements, for instance rare-earth metals in magnesium alloys.

Research

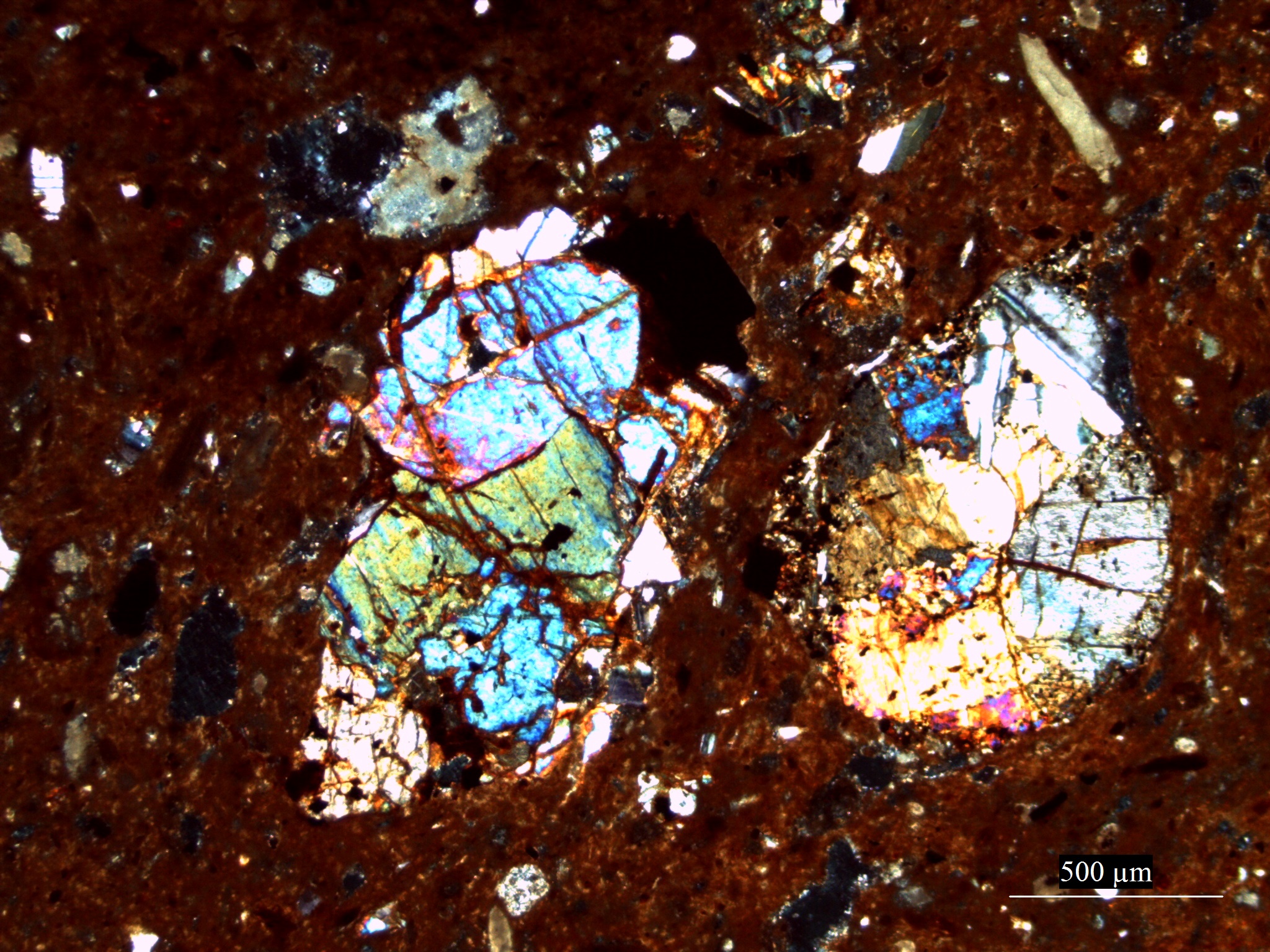

Metallic alloys, be it based on iron, aluminium, magnesium or titanium matrix, owe their properties and performance to the assembly of phases and defects that we call the microstructure. Thermodynamic characteristics and kinetic processes on the nano- and micro-scale control the formation of the microstructure during thermomechanical treatments. The physical background of metallurgical processes is studied experimentally and theoretically in order to understand the relationship processing-microstructure-properties across the length scales. Main topics in this research are the development of advanced high-strength steel and aluminium alloys….

The theoretical understanding of phase transformations and diffusion phenomena in metals and alloys is fundamental to explain experimentally observed metallurgical processes. One of the main goals of the “Microstructures” group is to gain insight on the microstructural changes that metallic alloys undergo during thermo-mechanical treatments, which implies proposing and solving thermodynamics and kinetics problems. This knowledge allows for chemical and microstructural control and, thus, for the design of processing routes resulting in the optimum mechanical and performance properties. Processes such as nucleation and growth, mobility of interfaces and redistribution of alloying elements are investigated by combining experiments with physically based models as well as with atomistic and phase-field simulations.

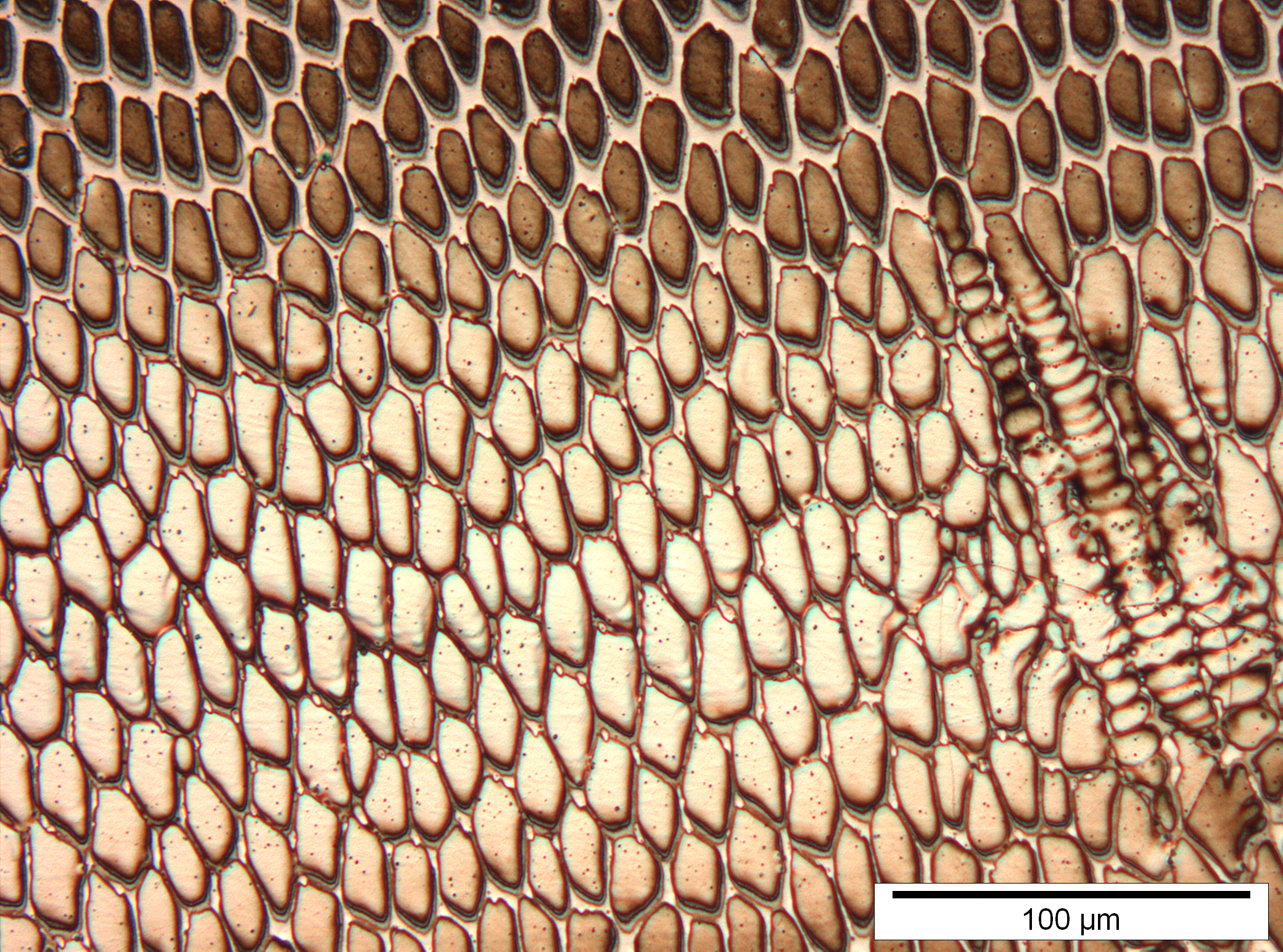

The optimisation of the mechanical behaviour of metallic alloys comes only with the understanding of the relationships microstructure-mechanical properties. The behaviour of metallic microstructures extends across several length scales and can be very complicated depending on the microstructure. Multi-phase metallic microstructures consist of several phases, with different morphologies, sizes and spatial distributions. Thus, their mechanical response is too complex to be predicted by just the modelling of average properties and phase fractions. Microstructural features, chemical and crystallographic properties and dislocation behaviour have to be considered.

In order to build quantitative models to relate microstructure and mechanical properties, it is required a strong coupling between microstructural and mechanical characterization together with statistical approaches. These data are used for the development of 3D micromechanical models able to reproduce the evolution and deformation behaviour of multiphase microstructure and, eventually, to predict their mechanical response.

The long term behaviour of a metallic material under specific external conditions, such as an applied load, fatigue, abrasion, corrosive atmosphere or radiation, depends on the response of its microstructure. At the core of the group’s activities lays the investigation of the formation of damage at the microstructural scale on applications-related properties. One of the goals is to bridge the gap between performance properties, such as formability, weldability, resistance to fatigue, wear, corrosion or radiation, and microstructural features associated with damage in order to develop microstructurally-based failure criterions. The physical understanding of the damage mechanism along with the microstructural control during the processing allow the optimum design for a certain application.