Create fuels out of it, with the aid of green electricity

If we want to make the world more sustainable, then we need to find a solution for CO2. Professor Wiebren de Jong (TU Delft) from the Department of Process & Energy (Large-Scale Energy Storage section, LSE) is working hard on this problem.

![]() He wants to capture emissions from fuels and other bulk chemicals. A project will be launched in April to convert that into formic acid. De Jong sees opportunities for the long term for transport fuels and the storage of sustainable electricity.

He wants to capture emissions from fuels and other bulk chemicals. A project will be launched in April to convert that into formic acid. De Jong sees opportunities for the long term for transport fuels and the storage of sustainable electricity.

It’s the problem of our time: carbon dioxide (CO2). Carbon dioxide is released when we burn gasoline, diesel, gas or coal, and it accumulates in our atmosphere. There it acts as a warm blanket that raises the planet’s temperature and disrupts the climate. ‘If we want to address the climate problem, then we need to handle CO2 in a smarter way,’ De Jong says. ‘The key to a sustainable future lies in closing the CO2 cycle. By making fuels out of CO2 again, for example, or raw materials for industry.’

That makes sense, but it’s going to take serious technological development. The problem is that in chemistry this essentially harmless, colourless gas is a kind of terminal destination. The CO2 molecule is highly stable, and anyone intending to do something useful with it will have to put a great deal of energy into their effort. Figuratvely speaking, but also literally. Indeed, chemists are pretty jealous of nature. Plants use sunlight to produce sugars from CO2 and water, and from there they subsequently produce yet other substances. So it’s possible to use CO2, the only problem is that biological photosynthesis is not easy to replicate chemically. That’s why Wiebren de Jong has opted for a different approach. ‘There is an increasing amount of sustainable energy available in the form of electricity, derived from solar panels and wind turbines. In the future, we’re going to use that green electricity to drive chemical processes that convert CO2. That’s how we can produce fuels from CO2 again.’

![]() Professor Wiebren de Jong was appointed full professor of large-scale energy storage at the ME Faculty’s Department of Process & Energy. Several months prior to that he was also named part-time professor of integrated thermochemical biorefineries at the University of Groningen. Wiebren de Jong is an expert in the areas of thermal & chemical conversion and biorefinery. De Jong has been affiliated with TU Delft since he started conducting research for his PhD in 1996.

Professor Wiebren de Jong was appointed full professor of large-scale energy storage at the ME Faculty’s Department of Process & Energy. Several months prior to that he was also named part-time professor of integrated thermochemical biorefineries at the University of Groningen. Wiebren de Jong is an expert in the areas of thermal & chemical conversion and biorefinery. De Jong has been affiliated with TU Delft since he started conducting research for his PhD in 1996.

Storing electricity

If De Jong pulls that off, he will kill two birds with one stone. First, it will make transport by lorry, ship and aeroplane much more sustainable. ‘Electric power is too heavy for that, and the range is too small,’ De Jong says. ‘With “CO2 fuels” in the tank, the transport sector can create a closed CO2 cycle relatively easily, without having to make huge investments or changes.’

The second, equally important application, is derived from the fact that the processes De Jong is working on essentially store electricity in the CO¬¬2 fuels. This makes it possible to create a balance between the supply and demand of green energy. After all, the production of green electricity is rarely equal to demand. A solar cell delivers electricity when the sun is shining, but people only turn on their lamps once it has gotten dark. If you generate electricity with a wind turbine, it would be great if you could use it when there’s no wind. On top of that, production and consumption always have to be in equilibrium in the electricity grid. There’s little point propping a country full of solar cells if no one is consuming all that electricity on sunny days.

‘It’s crucial for a stable sustainable supply of electricity that you can store green electricity,’ De Jong says. ‘Of course that can be partly achieved with batteries. But chemical storage in CO2 fuels makes it possible to store electric energy on a huge scale.’ A plant running on CO2 fuels can then deliver supplemental electricity during those moments when solar cells and wind turbines are not producing enough. ‘This enables you to buffer supply and demand,’ De Jong says, ‘and reduce your dependence on conventional energy sources, such as coal and nuclear energy.’ Moreover, he adds, the CO2 fuels can also play a valuable role in ‘linking up the seasons’. For example, it would be possible to ‘save’ sustainable energy from the summer (sun) and autumn (wind) until the winter, when houses need to be heated up.

![]() Once CO2 has entered the atmosphere it’s not easy, chemically speaking, to use it anymore. ‘The concentration is 400 ppm,’ De Jong says, ‘a few hundredths of a per cent. That’s too high for the climate, nor is it optimal in terms of process technology.’ Indeed, he sees possibilities for using CO2 that is released in high concentrations, for example in power plant chimneys, waste incinerators and steel plants. Another possibility is to allow trees and plants to grow (because they absorb CO2) and subsequently use the biomass. Indeed, Wiebren de Jong is devoting a great deal of attention to that, in particular when it concerns the use of organic by-products.

Once CO2 has entered the atmosphere it’s not easy, chemically speaking, to use it anymore. ‘The concentration is 400 ppm,’ De Jong says, ‘a few hundredths of a per cent. That’s too high for the climate, nor is it optimal in terms of process technology.’ Indeed, he sees possibilities for using CO2 that is released in high concentrations, for example in power plant chimneys, waste incinerators and steel plants. Another possibility is to allow trees and plants to grow (because they absorb CO2) and subsequently use the biomass. Indeed, Wiebren de Jong is devoting a great deal of attention to that, in particular when it concerns the use of organic by-products.

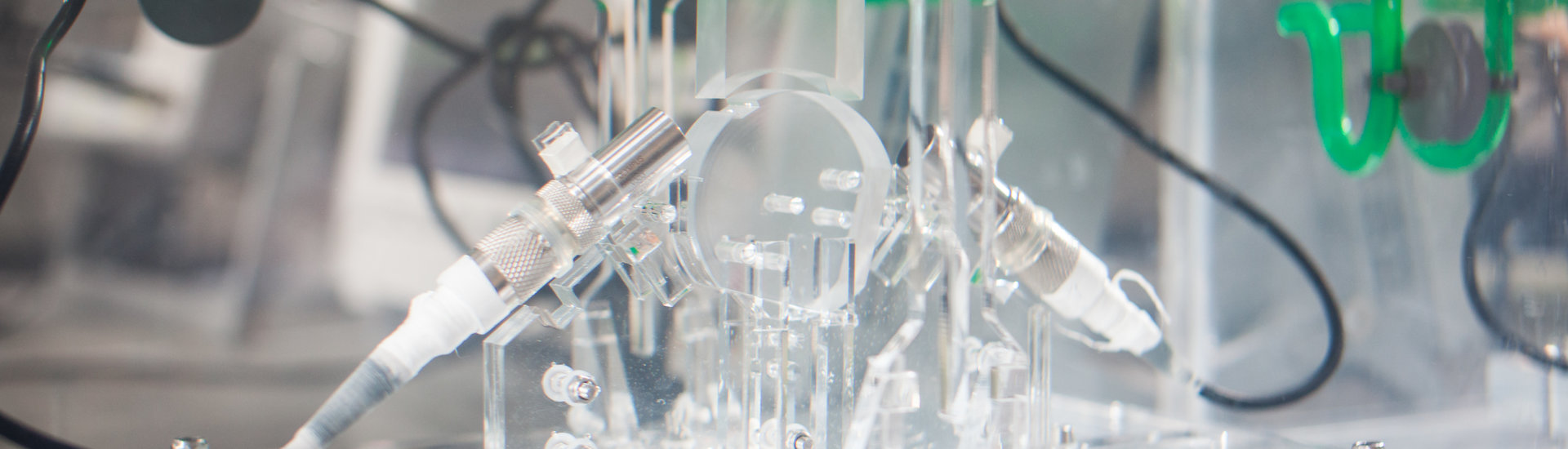

From lab to factoryDe Jong’s research is characterised by the ambition to ‘make something that works,’ as he puts it. His room borders the process hall with the ‘skids’: the technology set-up where new processes are developed and researched. ‘This is where ideas are transformed into reality,’ De Jong says. ‘We take what was conceived in a lab and carried out on a small scale in a fume cupboard and elaborate on it here in such a way that industry can really do something with it on a large scale. That means making optimal use of the thermal effects from the chemical conversion, for example. That’s how we create an integrated process that is essentially ready for large-scale use.’ The industry, or research institutes such as TNO and ECN, with which De Jong frequently collaborates, can then take the developments at the pilot plants to the next level.We have not reached this stage yet in the area of CO2 conversion. You can convert CO2 into CO with electricity, he explains. Carbon monoxide is much less stable and can therefore serve as a starting point for the synthesis of fuels and chemical raw materials. As is often the case, this is all easier said than done. Efficient electrodes are needed to introduce electric energy into the reactor; the CO2 has to be dissolved in the reaction solvent; good catalysts are needed; and it’s still a challenge to direct the complex interaction of chemical reactions is such a way that you end up with the desired product. ‘Still plenty of work to do,’ De Jong summarises.

![]() The ME Faculty’s Process & Energy Lab, which has just entered its second year, is the hub for all of TU Delft’s large-scale research in the area of process and energy technology. It is the only one of its kind in the Netherlands. The research being conducted at Delft in this area takes place in six sections: intensified reaction and separation technology; energy technology; large-scale energy storage; fluid dynamics; multi-phase systems; and engineering thermodynamics.

The ME Faculty’s Process & Energy Lab, which has just entered its second year, is the hub for all of TU Delft’s large-scale research in the area of process and energy technology. It is the only one of its kind in the Netherlands. The research being conducted at Delft in this area takes place in six sections: intensified reaction and separation technology; energy technology; large-scale energy storage; fluid dynamics; multi-phase systems; and engineering thermodynamics.

Formic acid

An interesting example of the use of CO2 is its conversion to formic acid. That is a ‘fuel’ for battery-free electric cars, but also a sustainable raw material for the chemical industry. The latter is keen to become ‘greener’ and is therefore prepared to invest. ‘Of course, the knowledge that we are developing,’ De Jong says, ‘is important for the real large-scale processes that will take place in the long term, such as the production of transport fuels and “sustainable natural gases”.’

A special project was launched in April 2017 in which De Jong further developed the path from CO2 to formic acid together with TNO (project coordinator), start-up company COVAL Energy, Manure Processing Fryslân BV , and CE Delft. The FAST student team from Eindhoven, which developed a car based on formic acid, was involved as well. So far, the research has generated a prototype the size of a paving stone. ‘Now it’s important to push the process in a direction where it becomes relevant for industry. That means, among other things, bigger electrodes and higher pressure, for example. Together with TNO and in close collaboration with the Voltachem platform for electrochemical conversion, we are going to find out what that means for process technology.’

Formic acid

An interesting example of the use of CO2 is its conversion to formic acid. That is a ‘fuel’ for battery-free electric cars, but also a sustainable raw material for the chemical industry. The latter is keen to become ‘greener’ and is therefore prepared to invest. ‘Of course, the knowledge that we are developing,’ De Jong says, ‘is important for the real large-scale processes that will take place in the long term, such as the production of transport fuels and “sustainable natural gases”.’

A special project was launched in April 2017 in which De Jong further developed the path from CO2 to formic acid together with TNO (project coordinator), start-up company COVAL Energy, Manure Processing Fryslân BV , and CE Delft. The FAST student team from Eindhoven, which developed a car based on formic acid, was involved as well. So far, the research has generated a prototype the size of a paving stone. ‘Now it’s important to push the process in a direction where it becomes relevant for industry. That means, among other things, bigger electrodes and higher pressure, for example. Together with TNO and in close collaboration with the Voltachem platform for electrochemical conversion, we are going to find out what that means for process technology.’