Nanofluids: helping you harvest heat from the sun and fabricate your own microchips

‘In this cohesion project we’re doing fundamental ground work towards two completely different applications. The project is strengthening the contacts between our departments as well.’

What do systems that can harvest thermal energy from the sun have in common with inkjet printers that can print microscale chip-like features? Dr. Rene Pecnik (Dept. of Process and Energy) and Dr. Murali Ghatkesar (Dept. of Precision and Microsystems Engineering) found the answer to this question: both applications make use of fluids carrying minuscule particles of a billionth of a meter in size each, also known as nanofluids. Despite the differences between the two applications, the successful development of either requires in-depth understanding of the behaviour of nanofluids at extreme conditions, such as high pressures or temperatures. The researchers joined forces and set about studying these properties and showcasing their respective innovations in a cohesion project entitled "Solar energy <- Nanofluids -> Nanomanufacturing.” It’s an unconventional title for a project, admits Ghatkesar, ‘but we’re very happy with the results.’

Common interest

The two researchers got talking during a University Teacher Qualification course at TU Delft. Pecnik: ‘The second module of this course consists of all participants giving a mini-lecture on the topic they teach to students. That’s how I got acquainted with Murali’s work’. Although they work on very different topics and focus on engineering challenges at different length scales, Ghatkesar and Pecnik share a common interest: nanofluids, which are fluids carrying particles of sizes on the scale of the nanometre (one billionth of a meter). ‘We found that we are facing similar challenges in dealing with such nanofluids. At about the same time, the possibility to apply for a cohesion project was advertised.’

'Although we work on very different topics and focus on engineering challenges at different length scales, we are facing similar challenges in dealing with nanofluids’

High temperatures, high pressures

While Pecnik needs nanofluids to collect and store heat from the sun, Murali pushes nanofluids through narrow channels to deposit nanoparticles on a surface in an inkjet-like process. In both cases, temperatures and pressures are higher than reference values for which the behaviour of the nanofluids is fully understood. ‘We both needed to know more about the fluid properties at those conditions, such as their viscosity, thermal conductivity and heat capacity. The cohesion project provided an excellent means to do foundational research, while also giving us the opportunity to move our respective ideas to a proof-of-principle stage.

‘The cohesion project provided an excellent means to do foundational research and move our respective ideas to a proof-of-principle stage’

Contacts between departments

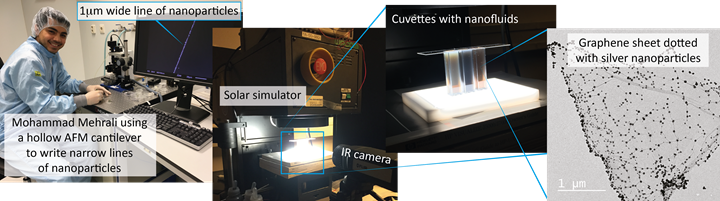

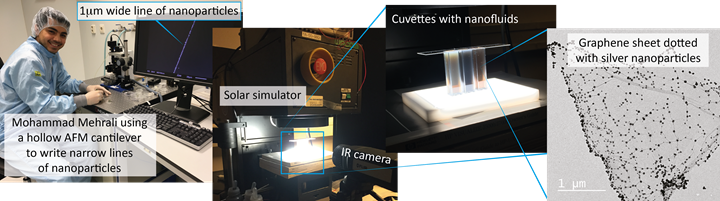

Pecnik: ‘In Dr. Mohammad Mehrali we found a postdoc specifically experienced in handling nanofluids and synthesising nanoparticles for energy applications. Over the course of the project, he successfully strengthened the contacts between our departments, as well as with researchers from other disciplines at TU Delft.’ Finding the right experimental equipment was tricky, says Ghatkesar, ‘but Mehrali was very persistent.’

‘Our postdoc successfully strengthened the contacts between our departments, as well as with researchers from other disciplines at TU Delft’

Volumetric solar receivers

Pecnik is working on harvesting heat from the sun, as a source of renewable energy. This is a complementary route to generating electricity from sunlight using photovoltaics. Sunlight is concentrated into a receiver containing a fluid, heating it up. This heat is either stored or used, for example to generate electricity. Compared to photovoltaics, which exploits only a narrow band of wavelengths, heat can be generated by the sunlight across the full spectrum. The key element of a system harvesting thermal energy from the sun is the solar collector, which absorbs the concentrated solar radiation, converts it into heat and transfers the heat to a heat transfer fluid. Since about 10 years, researchers are considering nanoparticles dispersed in the transfer fluid for this purpose. Due to their small size, nanoparticles allow much better heat transfer to the surrounding fluid. If the nanoparticles are dispersed in a high-pressure fluid, the efficiency of the conversion technique has the potential to be doubled. ‘It’s a highly promising and low-cost option compared to current systems,’ Pecnik summarises.

‘Using nanoparticles in volumetric solar receivers is a highly promising and low-cost option’

Graphene

‘As part of the cohesion project, we also came up with the idea to incorporate a graphene carrier sheet onto which the nanoparticles are placed.’ As graphene is an excellent thermal conductor while minimally obstructing the passage of sunlight, it further improves the efficiency of the heat-harvesting process. ‘All in all, we increased the power conversion efficiency from 30% (pure water) to 77% (water plus graphene plus nanoparticles), which is a significant result’.

Nanomanufacturing

At the same time, Ghatkesar was poised to realise an inkjet-like printer system capable of precisely depositing nanoparticles onto surfaces. Sharp needles, well-known from a widely used experimental technique called scanning-probe microscopy, are etched until a hollow channel extends to the tip of the needle. The hollow needle can be moved with nanometre accuracy. If a nanofluid is pushed through the channel and deposited on a surface, the moving needle will leave a dotted trail of nanoparticles. The final step is a thermal treatment, which causes the nanoparticles to fuse together. In this way, Ghatkesar aims to fabricate micro and nanometre-sized strips. These strips can be metallic, for use in microelectronics. They can also be built up from fused diamond nanoparticles, combining high mechanical durability with biological and chemical sensing capabilities.

Table-top micro-nano-printer

For Ghatkesar, there is much riding on the cohesion project. ‘I proposed the idea of printing micro/nanosystems before but lacked a proof of principle to obtain funding. Despite this setback, I really did not want to kill off the idea. The cohesion project allows me to obtain crucial initial results to give credibility to a larger research proposal.’ Looking ahead, he isn’t short of ambitions either. ‘I’d love to develop an affordable table-top system to fabricate microsystems, both for electronics and mechanics. Currently, the fabrication of such small-scale systems requires energy-intensive complex equipment in an expensive cleanroom environment, where levels of dust and other ambient conditions are tightly controlled to prevent contamination of the microsystems. For many users, this is too expensive. An inkjet-like printer could bring such fabrication capabilities to a much wider group of users.’

'I’d love to develop an affordable table-top system to fabricate microsystems, both for electronics and mechanics’

Dr.ir. Rene Pecnik (Dept. of Process & Control) is associate professor in the area of fluid dynamics of energy systems. He obtained his PhD degree cum laude in 2007 from Graz University of Technology (Austria) after which he was postdoctoral researcher at Stanford University (US). His expertise is in the area of fluid mechanics, turbulence modelling and thermodynamics.

Dr. Murali Ghatkesar (Dept. of Precision and Microsystems Engineering) graduated summa cum laude from the University of Basel in Switzerland. After that he worked among others at CalTech and the University of Virginia in the US. As assistant professor ‘Micro and Nano Engineering’ at the TU Delft he develops micro and nanotechnology-based tools to help solve intriguing problems in biology/chemistry and unravel some of the mysteries of nature at small scales.

ME Cohesionprojects

ME Cohesionprojects

The cohesion projects were launched in 2014 based on an idea by Dean Theun Baller, the aim of which is to encourage interdisciplinary cooperation within the faculty. A good engineer, after all, is inherently good at working with others, and most innovations take place on the cutting edge of disciplines. The cohesion projects give young researchers the opportunity to ask for funding for projects, on the condition that they work together with colleagues within the faculty and outside their own discipline. Mechanical Engineering, Maritime Technology and Materials Science have proven to be extremely suitable for unexpected cross-overs with surprising outcomes.