If algae and specifically diatoms can be used to increase the efficiency of environmentally friendly anti-corrosion coatings, we could protect all kinds of structures – aircraft, trains, military tanks and so forth – without using toxic and expensive materials.

The use of coatings is one of the most widespread approaches for protecting metallic structures against corrosion. Such coatings use passive and active protective methods such as barrier against corrosive species and corrosion inhibitors. For almost 100 years, corrosion inhibitors based on chromium VI have been used in coatings to maintain the protective function even after damages have occurred. Though efficient, these particles are highly toxic and carcinogenic. As a consequence, the consumption of chromates has already been banned in many applications and is a constant target for the highly demanding aerospace sector where its banishment has been delayed several times due to the lack of sufficiently good alternatives. The use of algae, and specifically the exoskeletons of the algae group known as diatoms, might help us create the alternative the world is looking for.

Along 2015, Assistant Professor Santiago Garcia at the Novel Aerospace Materials group, set up a project to explore the potential use of diatom exoskeletons (or: frustules) to protect aerospace structures. Garcia: “In 2015 we made the first proof of concept to demonstrate that algae can be used for active corrosion protection and self-healing applications. I believe this could potentially have a huge impact.”

Why diatom frustules?

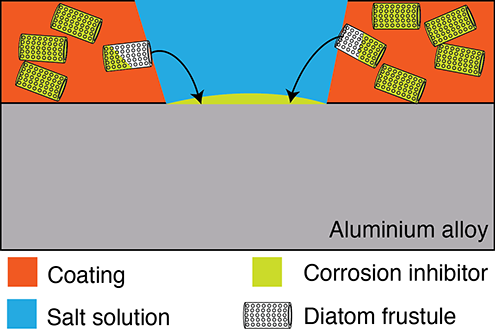

There are already a few examples of promising corrosion inhibitors that might replace chromate. However, studies have shown that unwanted reactions occur between these inhibitors and the surrounding coating matrix thereby minimizing their inhibiting efficiency. A way to avoid this is to encapsulate the inhibitors inside carriers. Using a carrier reduces the interaction between the inhibitor and its surroundings, and in addition it can be used to control the release of the corrosion inhibitors. This strategy can theoretically result in much more efficient anti-corrosive coatings.

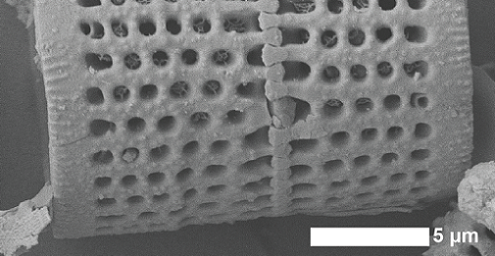

Frustule of the Aulacoseira type diatom (diatom exoskeletons)

The frustules can function as such a micro-sized carrier. Why is their specific architecture suitable for the task? PhD researcher Paul Denissen explains: “Frustules are hollow nanoporous silica microparticles referred to as ‘pill-box’ structures. They have a cell wall made of silica, a strong structure with pores. Luckily for us, these pores are big enough to allow the corrosion inhibitors in and out.”

Studying individual particles

After his MSc thesis on this topic Paul Denissen started his PhD research last January and is looking into the isolation and study of individual frustule particles by means of advanced characterization techniques. Garcia: “Frustules show a wide diversity in shapes, sizes and porosity (namely architecture). Dedicated tests need to be performed to find out how the individual particles behave and how we can influence that behaviour. In short, we want to:

- Explore the potential use of diatom exoskeletons and demonstrate that they can be used for doping and controlled release of functional species in coatings such as corrosion inhibitors.

- Evaluate what the effects of the architecture and geometry are on the release and efficiency of corrosion inhibitors.

- Modify the surface of diatom exoskeletons and apply certain triggers such as changes in the pH level to control the release of corrosion inhibitors.

If we understand this, we can start making coatings that only release the required amount of corrosion inhibitors at the right time using highly available raw materials. “

Corrosion protection mechanism of coatings containing inhibitor-doped diatom exoskeletons

Nature’s solution to an industrial problem

The NovAM group is now specifically looking at high strength aluminium alloy 2024 used in aerospace manufacturing, which is very susceptible to corrosion but the trick can be used to protect all kinds of metal alloys. Denissen explains that this self-healing mechanism could also be used for other applications in the future: “Every inhibitor has certain characteristics which have certain effects when encapsulated in a carrier. Once we have quantified individual particles and measured how they behave, we can decide on which particle is best for a specific application, such as aircraft.”

If algae and specifically diatoms can be used to increase the efficiency of environmentally friendly anti-corrosion coatings, we could protect all kinds of structures – aircraft, trains, military tanks and so forth – without using toxic and expensive materials. Garcia: “Diatoms occur in virtually every environment that contains water. Reproduction among diatoms is by spores and asexual by binary fission and they have a very high growth rate. Using frustules to make active anticorrosive coatings would not only present a healthier solution to current synthetic approaches, but it would be up-scalable, sustainable and inexpensive as well. This new concept follows the line with our ongoing research on self-healing polymeric systems and new functional micro and nano fibres for composites and coatings made out of algae.”