Concrete Recycling

Concrete (ca 35 €/ton, 90 €/m3) is the largest structural material in terms of volume: EU production of ready mixed concrete is about 300 million m3 per year. At the End-of-Life phase, concrete is mainly land filled or recycled into road-based aggregate (RBA), quite often in a mix with other mineral waste materials (bricks, tiles) from the same building. Eventually, neither land filling nor road building is a sustainable solution for concrete waste, although recycling concrete into RBA has important advantages: steel rebars are recovered, crushed concrete is reused in a suitable application and transport of bulk materials (energy, dust) is minimal, particularly if mobile crushing installations are applied at the demolition site. A main problem with the RBA route is that the building of new roads needs less and less material while the volumes of EOL concrete are rising. The two developments together result in a surplus of concrete waste that cannot be absorbed by the road sector. Another issue is that the production of cement from primary materials (limestone) is responsible for about 10% of the world’s CO2 emissions. High-grade recycling of EOL concrete liberates the old cement paste from the concrete which can then be recycled into new cement with lower CO2 emissions.

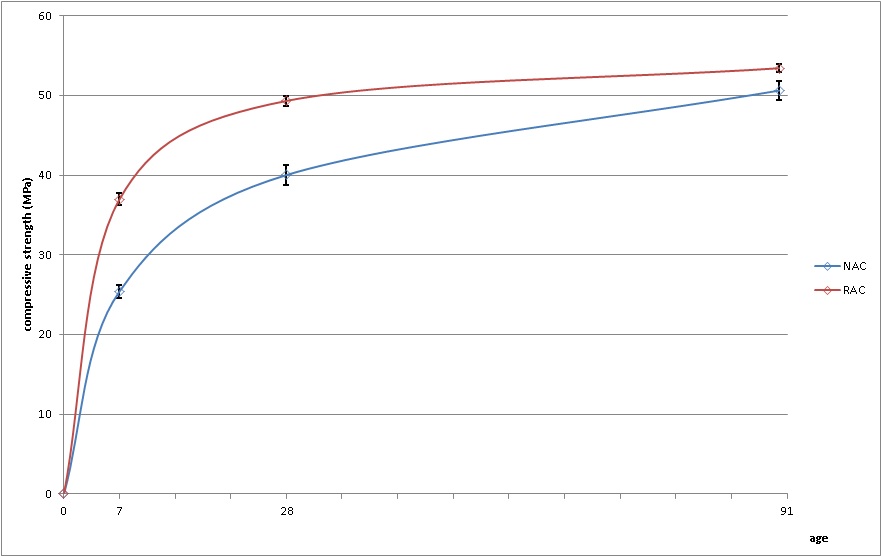

The aim of the Delft research is to create a high-grade recycling process for EOL concrete that is economically competitive with the RBA route but environmentally superior and more sustainable. This high-grade recycling process turns crushed EOL concrete into aggregates for new concrete and a fine cement paste concentrate for making new low-CO2 cementitious binders. The process first mills the crushed concrete gently to remove most of the cement paste and fine sand from the surface of the concrete particles, and then separates off the cement fines, wood and other light contaminants into a cement paste concentrate. One of the most challenging parts of the research is to make the process fully mobile for application at the demolition site, and yet control and certify the quality of the aggregate products to the point that they are widely accepted as a replacement of primary aggregates: by regulatory agencies, mortar facilities and end-users. In order to make this happen, advanced on-line sensors are being developed that record the composition and grain-size distribution of every truck-load of aggregate, so that the material can be shipped directly from the demolition site to the mortar facility. The work at Delft is part of the European C2CA project.

Other solutions

Kemco process

VAR process

Washing

Research team

Abraham Gebremariam

Ali Vahidi

Francesco Di Maio

Maarten Bakker

Peter Berkhout

Peter Rem

Sponsors

European Commission (FP 7, Environment)

Partners/collaboration Strukton University of Rome (La Sapienza) AGH-University of Science and Technology Heidelberg Cement Institute of Chemical Engineering and High Temperature Chemical Processes Inashco R&D Leiden University Barcelona Supercomputing Centre Centro National de Supercomputación DV s.r.l. Technical University Denmark Holcim Laser 2000 Theo Pouw Decistor

Results

Papers

Lotfi, Somayeh; Deja, Jan; Rem, Peter; Mróz, Radosław; van Roekel, Eric; van der Stelt, Hans,

A Mechanical Process for In Situ Recycling of EOL Concrete, SB13 Singapore, 9-10 September 2013 (2013)

Presentation: Concrete recycling