High-rate VFA production from industrial waste using the granular sludge process

Researcher: Alexander Hendriks Promotor: Prof. Dr. Ir. Jules van Lier

Supervisor: Merle de Kreuk

Research objectives

For the production of bioplastics, polyhydroxyalkanoate (PHA) can be used as raw material. For efficient PHA production, volatile fatty acids (VFAs) are needed, which can be obtained through anaerobic fermentation using low-grade wastewater. Using granular sludge technology for the fermentation process could enhance conversion efficiencies, reduce reactor size and will lead to biomass free, but VFA rich effluent. The application of granular sludge technology for VFA production of wastewater is however a largely unexplored research topic. Aim of this research is to develop a novel reactor technology using different operational conditions and (mixtures of) substrates and study its effect on granule formation and VFA product spectra.

Project outline

Introduction

Polyhydroxyalkanoates (PHAs) are biopolymers produced by many different bacteria as an intracellular carbon and energy reserve material. In response to the problems and harmful effects of plastic wastes on the environment, PHAs attract considerable attention as alternative for petroleum based plastics because they are biodegradable and made from renewable resources (Braunegg et al., 1998; Leaversuch, R., 1987). This research will focus on the production of a VFA rich medium from effluent of agro- and food industries. This medium could be used hereafter for bioplastic production or utilised differently.

Approach

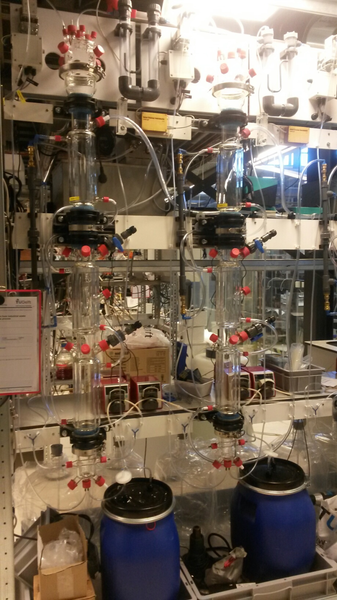

For efficient PHA production, the conversion of organic substrate into VFA should be maximized, the VFA composition should be controllable, production of hydrogen and methane gas should be avoided, biomass concentrations in the bioreactor’s effluent should be minimized and the reactor should be as compact as possible to minimize investment costs. A possible way to fulfill these objectives is by using a granular sludge process. The research will focus on granule formation, stability and the effects of operational conditions, like temperature and pH, and suspended solids as substrate on granules VFA production and VFA spectra. Figure 1 gives an overview of the reactor setup that is going to be used for this research.

Results

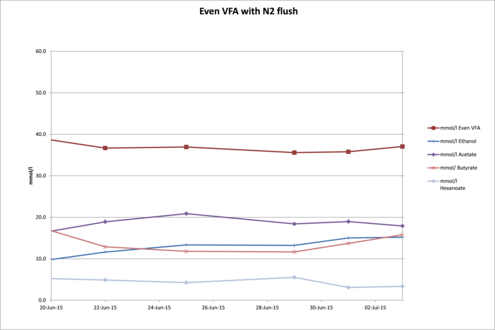

The project aims on elucidating typical process engineering related aspects of the process like the impact of solids retention time and operational variables. Figure 2 is an example of the temperature and pH dependent growth rate of Clostridium butyricum according to a Cardinal growth model. Experiments will be conducted with specific substrates and mixtures of substrates (artificial wastewater). Also the influence of (un)degradable solids on the granule formation and VFA product spectrum will be investigated.

Scientific relevance

The application of the granular sludge technology for pre-acidification of wastewater is a largely unexplored research topic. This results of this research should shed some light on the effects of different operational conditions and (mixtures of) substrates on granule formation and VFA product spectra.

Social relevance

As mankind we should shift to a more sustainable and biobased society. VFA’s are a useful building block for products in this biobased society, as for bioplastics. The results of this research will bring valorization of wastewater streams a step closer.

Literature

- Braunegg, G., Lefebvre, G., Genser, K.F., 1998. Polyhydroxyalkanoates, biopolyesters from renewable resources: physiological and engineering aspects. Journal of Biotechnology 65 (2-3), 127-161.

- Johson, K., Jiang, Y., Kleerebezem, R., Muyzer, G., Van Loosdrecht, M.C.M., 2009. Enrichment of a mixed bacterial culture with a high polyhydroxyalkanoate storage capacity. Biomacromolecules 10 (4), 670-676

- Leaversuch, R., 1987. Industry weighs the need to make polymer degradable. Modified Plastics 64, 52-55

Figure 1. Reactor setup

Figure 2: Example of a fermentation pattern during a stable period