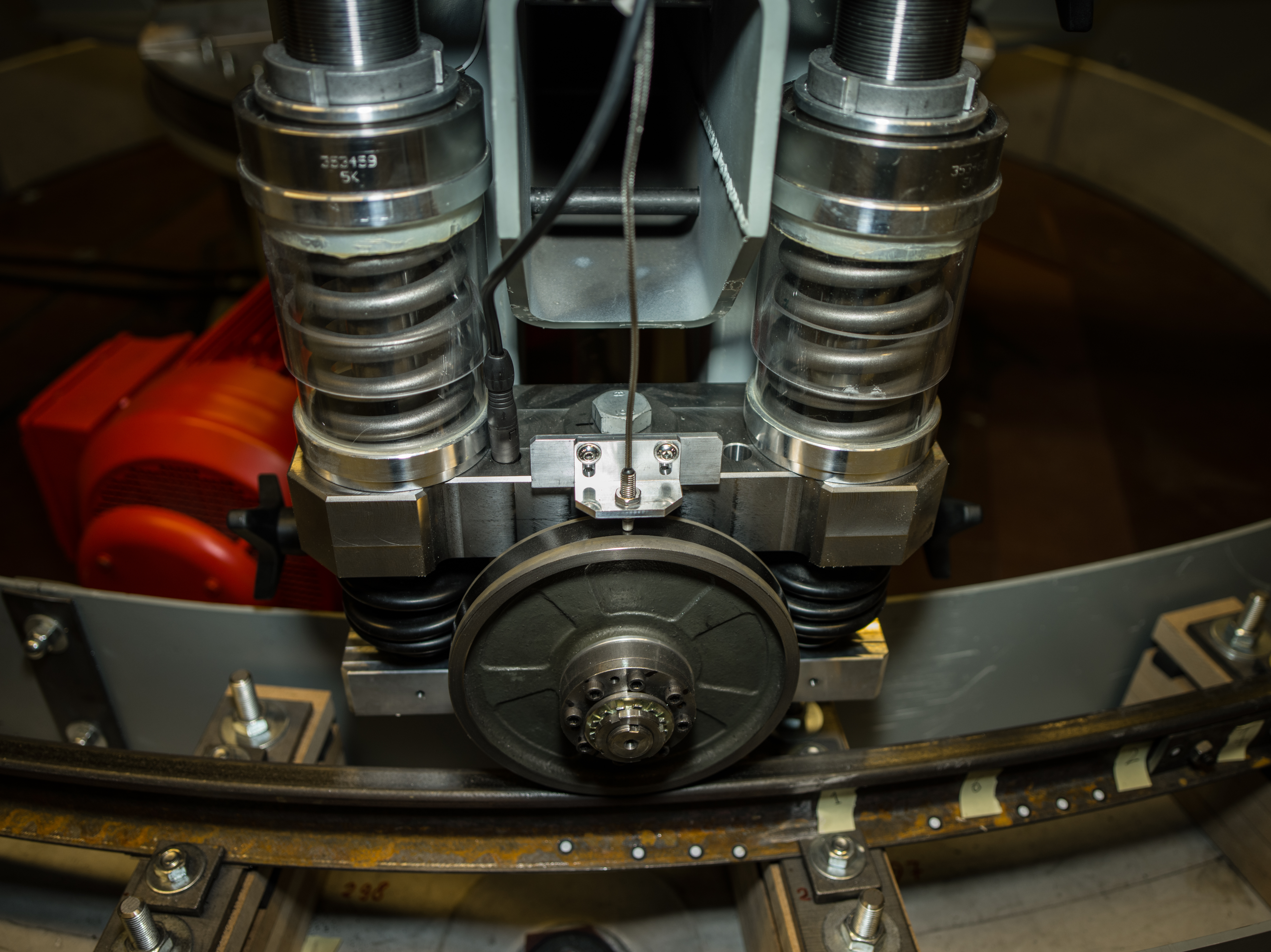

One mouse click and the iron cross behind the glass groans to life. This is a new test installation to research wear on railway material.

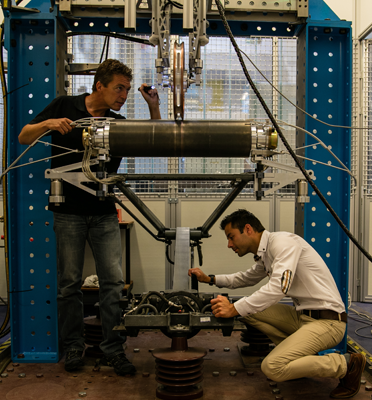

With nearly 100 h.p., the hefty engine can accelerate the 4-metre-wide cross to 1 revolution per second. That is a fairly impressive speed, certainly when you are standing right next to the spectacle. Four times a second, a mini railway wheel races over the mini railway in the basement of the building housing the Faculty of Civil Engineering and Geosciences.

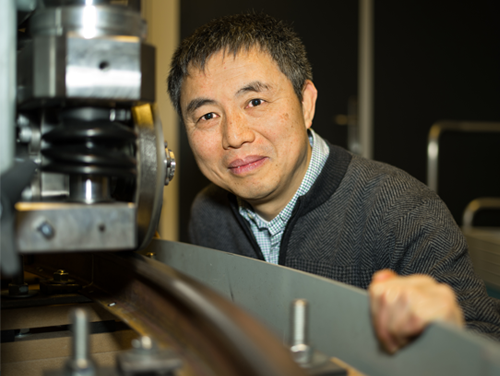

Dr Zili Li watches the installation proudly. He funded the million euros required for the test installation with work conducted by the railway engineering laboratory for external clients over the past decade. “A week on the test track is comparable to a year on the railway network,” explains Li.

Every 10 seconds, 40 axles crash over each point of the circular rail – equivalent to a train every ten seconds. The speed of 11,4 m/s on the test track is also equivalent to the 280 km/h speed achieved by a TGV train, thanks to the 1:7 scale. Spring tension can be used to increase the force exerted on the wheels to 5.000 newton, which is the equivalent to 2,5 gigapascal (normal is 1 gigapascal). And to accelerate wear and fatigue even further, the wheels can be driven forward and braked, corresponding to the additional wear and fatigue on wheels and rails under a locomotive.

During the tests, wear on the wheels is measured down to the micrometre. The threedimensional acceleration measured in the bearings corresponds to the measurements conducted by the TU Delft ‘measurement train’ – a reallife carriage that travels on the Dutch railway network. The laboratory situation and reality are therefore comparable.

Li really comes into his own when asked about potential applications. Wear and fatigue measurements form the essence of theoretical descriptions. Measurements that can be effectively reproduced are necessary in order to test mathematical models. A mathematical model for rail wear and fatigue needs to link force and tension on the one hand with material composition and microstructures on the other. A valid model could potentially be used to design better quality materials that are less susceptible to wear and fatigue. Conversely, it is conceivable that the design of the rail and wheel could be improved, meaning that the current materials last longer.

Whichever route is ultimately chosen, all improvements begin with thorough and reproducible measurements. And that is something that recently became possible in a basement in Delft.

This story originally appeared in the Delft Outlook.