Facilities

Milling

Milling: A wide range of very precise milling work is possible.

Fehlman Picomax 825 Versa:

- Enhanced precision version

- Precision: 0.001 mm per axis

- Ability to mill 5 axes simultaneously

- Equipped with an Erowa zero-point workholding system

Fehlman P90, P60, P56 TOP and several P55 machines

- With the 4th and/or 5th rotation axis

- Well-suited for carrying out complex fine-precision milling

- Ability to work with milling depths of up to 0.01 mm.

- A CNC simultaneous 5-axis milling machine with a maximum table travel of 850 x 700 mm and a height of up to 500 mm

Multiple Hermle CNC simultaneous 5-axis milling machines

- A maximum table travel of 850 x 700 mm and a height of up to 500 mm

- Maximum workpiece weight: 1400 kg (Hermle C40)

CNC simultaneous 3-axis machine (Hermle U1130):

- A maximum table travel of 700 x 1100 mm and a height of up to 800 mm

Various conventional milling machines:

- Maximum table travel of 600 x 800

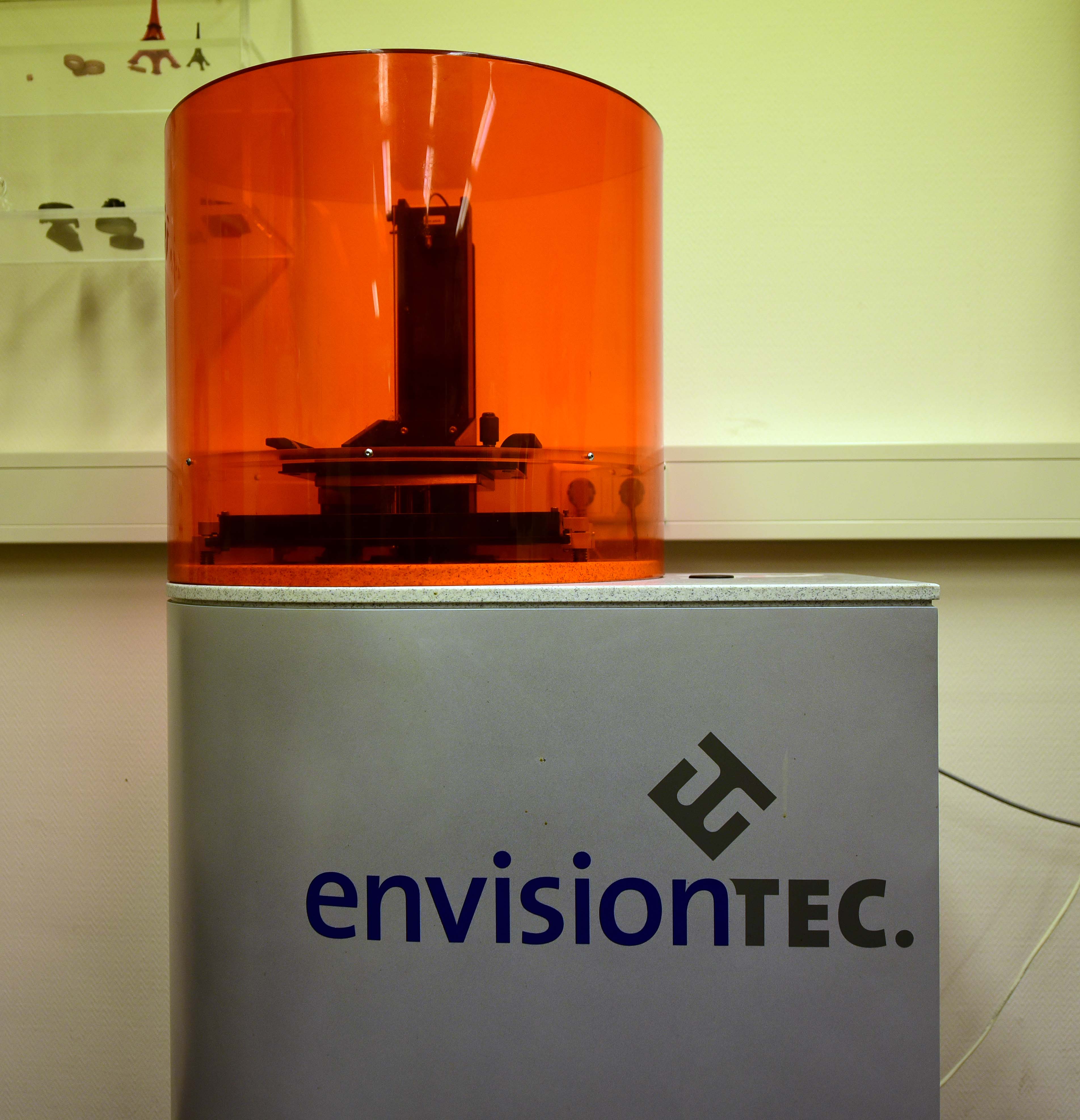

Plastic 3D printing

Two build platforms with different sizes:

- 1 platform is 115 x 72 x 230 mm with an xy resolution of 30 µm and

- 1 platform is 84 x 52.5 x 230 mm with an xy resolution of 21.5 µm

- Both platforms have a z-axis resolution of at least 25 µm.

Various types of plastic material can be printed

Examples:

- High temperature resistant material

- Ceramic-filled plastics

- Biocompatible materials

- ABS and rubber-like materials

3D Metal printing

Sisma Mysint 100 PM

- Building volume of 100 x 100 mm high in diameter

- In principle, stainless steel is used for printing, but other materials such as aluminium, titanium and bronze are also possible

- The printer is fitted with a glove box to enable reactive materials such as titanium to be printed.

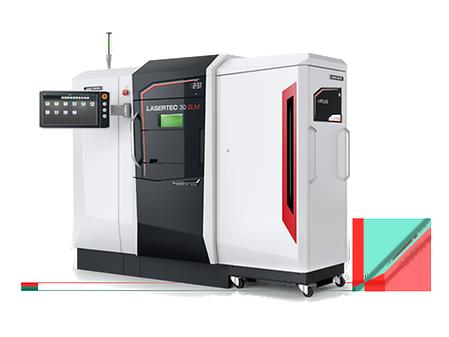

DMG Mori Lasertec 30 SLM (from 2021 on in its last testphase)

- Powder bed with 300 × 300 × 300 mm construction volume

- High precision building of 3D parts with layer thicknesses between 20 and 100 µm for maximum productivity

- Dynamic adjustment of the focus diameter between 70 and 200 µm

- Application-specific fibre laser sources of 600 W

- Optimised shield gas volume flow for highest component quality with minimum Argon consumption < 72 l / hour

- Maximum work safety due to closed material cycle and integrated powder recycling

- Material exchange via replaceable powder module

Modifying plastic

There is a separate workplace for modifying plastics

- Modifications to a wide variety of plastics are possible

- CNC milling, lathing, sawing and planing

- Connecting plastics by welding or glueing

- Bending the plate and tube

Welding

Laser welding:

- Trumpf pulsed laser 5004

- Max. 5 kW

- Max. weld spot size 2.236 mm

- Min. pulse power 250 W

- max. pulse power 5 kW

- Min. pulse time 0.2 ms

- Max. pulse time 50 ms

Orbital welding:

- Diameters of up to 38 mm, including the possibility of welding connectors to the tube

- Each weld can be recorded and stored in digital form

TIG and MIG welding of:

- Stainless steel

- Aluminium

- Steel

Welding

Laser welding:

- Trumpf pulsed laser 5004

- Max. 5 kW

- Max. weld spot size 2.236 mm

- Min. pulse power 250 W

- max. pulse power 5 kW

- Min. pulse time 0.2 ms

- Max. pulse time 50 ms

Orbital welding:

- Diameters of up to 38 mm, including the possibility of welding connectors to the tube

- Each weld can be recorded and stored in digital form

TIG and MIG welding of:

- Stainless steel

- Aluminium

- Steel

Water jet cutting

Omax micro water jet cutting machine

- Work envelope: 650 x 650 mm

- Axes: controlled X, Y and A axes , fixed Z axis

- Precision: high precision of 0.01 mm

- Cutting area: from 0.1 mm to 25 mm material thickness (depending on material). With tilted jet, enabling dead square cutting on one side without divergence.

- Cutting pressure: 2800 bar (water leaves cutting nozzle at 300m/s)

- Options: Automatic abrasive feed system, abrasive removal system with hopper, water softener.

For the most up-to-date information, please contact Leon Roessen or Bert Bakker: info-demo@tudelft.nl