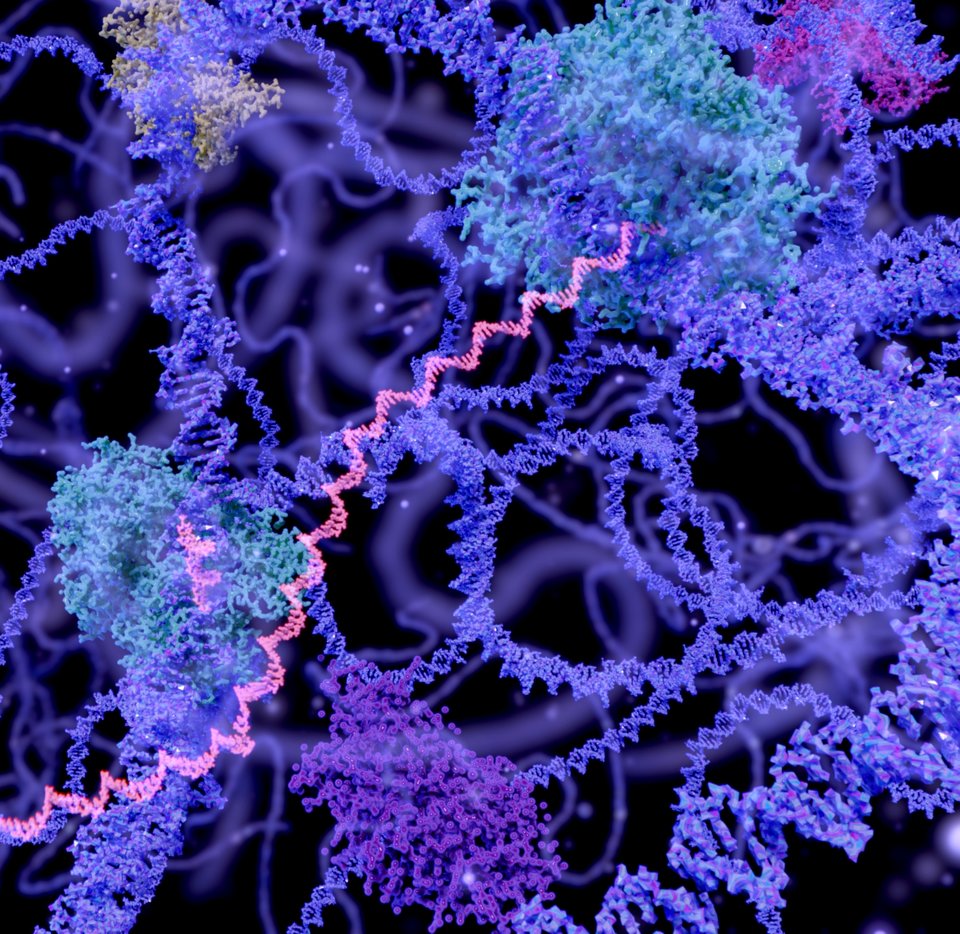

Innovation is crucial to fulfil the potential of industrial biotechnology for sustainable production of fuels, chemicals, materials, food and feed. Similarly, scientific and technological advances in environmental biotechnology are needed to enable novel approaches to water purification, and ‘waste-to-product’ processes thus contributing to a circular economy. Increased fundamental knowledge encompassing enzymes, microorganisms and processes are essential for progress in this field. The Department of Biotechnology covers this research area and, based on new insights, selects, designs and tests new biobased catalysts, micro-organisms, and processes.

The department encompasses five research sections: