Section Materializing Futures

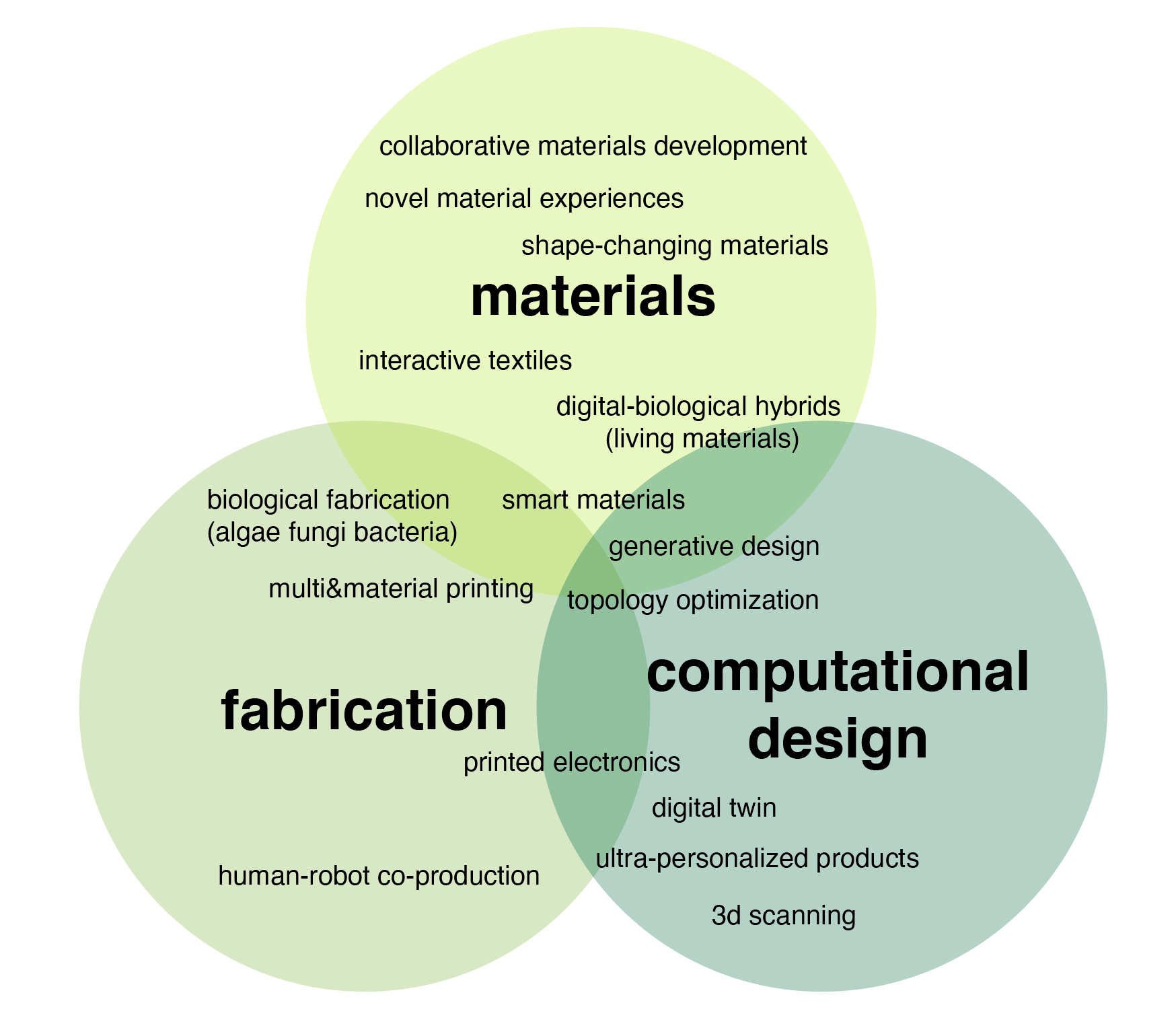

The section of Materializing Futures aims at developing theories, tools, and methods to empower future designers in understanding and designing with emerging material and fabrication technologies in the interest of the planet and society. Our research activities are organised under three interconnected pillars: Materials, Fabrication, and Computational Design.

Materials

The definition of materials in design is more extensive than ever. Materials can possess living-like properties, they sense and adapt through computational and biological programmability. As materials become alive, responsive and adaptive, and acquire new functionalities and expressions, how should designers work with them? What new skills and competencies do they need? What type of novel tools and techniques do we need to develop to better understand and convey such materials to future designers?

The main research activities under this area concern developing an understanding of the potentials of smart and living materials for product design to support and inspire future design research and practice. The researchers adopt a material-driven design approach, which suggests making and material tinkering central to the material understanding in design. The approach also suggests techniques to understand and integrate both the technical properties of a material and its experiential qualities (i.e., how it is received by end users) in unveiling the material’s design potentials. Specific research topics under this pillar include: design guidelines for shape-changing materials and interactive textiles, designing living artefacts, capturing and modelling adaptive material appearance, scaling-up research with living materials, collaborative material development, and novel material experiences and society acceptance.

Fabrication

We foresee that the field of product design will be revolutionized by the future fabrication technologies which takes both computation and biology central to the embodiment and manufacturing of future products. Accordingly, our Fabrication related research activities are organised under two main areas: Digital Fabrication and Biofabrication.

Digital Fabrication

The digital fabrication process, where digital data directly drives manufacturing equipment to form various geometries, in particular Additive Manufacturing (3d printing), is gradually extending its applications towards end-products in many different areas, from printing human organs to parts of aircrafts. Along a growing variety of materials that are being introduced, the continuing evolution of additive manufacturing is giving rise to possibilities to combine multiple materials into one single structure. The focus of our work within digital fabrication is on development and effective application of new fabrication techniques in product design, including multi-material printing, 3d printed metamaterials, 3d printed electronics, bioprinting, and human-robot co-production.

Biofabrication

The cross-fertilization of biology with design and engineering suggests new sustainable ways of fabrication in product design. The focus of our work within biofabrication is twofold: (1) researching the scaling-up opportunities for biologically fabricated materials, such as algae, fungi, and bacteria, as building blocks of future products, (2) exploring the possibilities when digital and biological fabrication techniques are merged to facilitate the desire functions and expressions in biofabricated products.

Computational Design

Computational design, which utilizes the computing power of computers and the intelligence of embedded algorithms, is able to help designers explore the solution space in a systematic and comprehensive manner. Using computational design, the role of designers is gradually evolving from doing computer aided-design (CAD) to instruct a computer to do the design. The importance of the digital twin of an object or system is growing in all design phases. Not only data of the object and system itself are incorporated, but also data of the user and user groups. The main research topics include ultra-personalized products, topology optimization, generative design, digital twin, 3D-scanning, computational tools for modelling human body and behaviour, smart materials, printed electronics, and digital-biological hybrids (living materials).

In the area of Sustainability, we particularly focus on biodesign and sustainable (multi-material) 3D printing. In biodesign, an example project is Living Artefacts, in which we explore the possibilities of micro-organisms when their livingness is prolonged to the use time of everyday products. From photosynthetic materials using micro-algae to bioluminescent materials from bacteria, we explore practical and social challenges in designing with and for such living materials, which offer novel responsive behaviour and interaction possibilities while promising minimum ecological footprint. For 3D printing, we are developing new approaches for harnessing the digital and additive nature of the technology to take it in a sustainable direction. We mainly aim at addressing the issues of material use and material recycling. By integrating material science with computational design and fabrication, we are exploring new multi-material combinations, structures, and 3D metamaterials to obtain properties that are not found in the used materials themselves. We see this as an essential step towards reducing the number of materials that a designer needs to choose from to give products the desired behavior.

In the area of Healthcare & Wellbeing, we focus on personalized product design, smart garments for unobtrusive health monitoring and garments for thermal control of the human body. In personalized product design, an example is the next UPPS project where shapes of (part of) human body can be digitized in real-time for generating personalized design based on computational design tools.

In the area of Mobility, we integrate tools and techniques from computational design and additive manufacturing to enhance better comfort and safety, while at the same time reduce the environmental burden. Three examples of projects are: the Flying V: the development of a sustainable aircraft with improves comfort; ComfDemo: making a digital twin containing a comfort model, which helps improving comfort; Sleeping in limited space: studying human sleep envelops to create small sleep facilities that are comfortable at the same time.