By: Agaath Diemel

Currently, storage is the key issue holding back the energy transition. Professor Fokko Mulder and CEO Mattijs Slee from Battolyser Systems are within reach of the solution: the Battolyser is a battery and a hydrogen factory in one. The TU Delft spin-off is a textbook example of how to create impact from research.

It is a familiar problem: the production of solar and wind farms varies throughout the day and across the seasons. In order to cope with these fluctuations, demand for storage is set to increase enormously. This is why Professor of Energy Storage Fokko Mulder embarked on his quest for alternatives for the ubiquitous lithium battery several years ago. A potential candidate was the nickel-iron battery, originally discovered by Edison, but never a commercial success. One of the reasons: when this kind of battery is being charged, water is electrolysed, producing hydrogen and oxygen. “For a long time, that hydrogen was seen as an undesirable by-product, but the energy transition has now transformed that disadvantage into an advantage. Instead of attempting to reduce the production of hydrogen, it became much more interesting to deliberately split that water”, explains Mulder.

This is the idea behind the Battolyser: an integrated appliance that serves as a battery for day- and night-time storage and starts to produce hydrogen when it is full. Hydrogen can be used for long-term storage, as a fuel or as an interim stage in the production of raw materials such as ammonia. “So, it’s a single device that replaces two. What also makes it so special is that the materials remain very stable when switching between the different functions: charging and discharging the battery and the electrolysis.” In addition, nickel and iron are very plentiful and conflict-free materials. “A gift from mother nature”, is what Mulder calls it. “In the context of the energy transition, this combination of materials turns out to have a unique set of characteristics. It is sublime in its simplicity.”

Upscaling to serial production

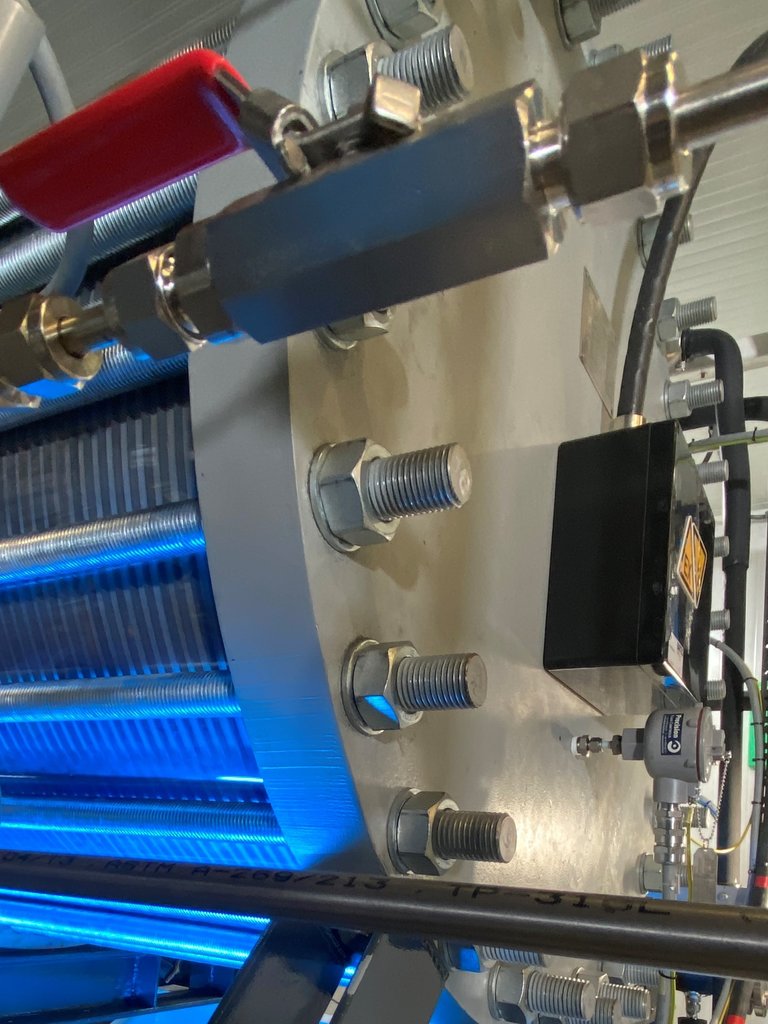

The prototype for Mulder’s lab has now been upscaled to a pilot unit the size of several households. “Next year, it will be installed at Vattenfall in order to demonstrate that the technology is also effective in an industrial setting”, explains Mattijs Slee, CEO of Battolyser Systems. Serious efforts are also being made to upscale the capacity, firstly by developing a commercial demonstration unit and then advancing to production capacity. Each stage will involve new issues relating to efficiency, feasibility and affordability. “The pilot is about proving that it works, but if it’s to be upscaled for commercial use, it will also need to be efficient, affordable and reliable. The phase after that will be commercial serial production, when we as a company will need to be able to earn money on every unit.”

That means that the current focus is on a lot of R&D, but as it becomes increasingly commercialised, Battolyser Systems will begin to attract more capital. “There’s a lot of interest in the market. The trick will be in the timing: if you act to early, it will be too expensive, but leave it too late and you’ll impede growth”, says Slee. Slee knows what he is talking about: before joining Battolyser Systems, he was responsible for investments in non-fossil fuel and raw materials applications at Shell Ventures. In addition, this young company has Kees Koolen, CEO of the clean energy conglomerate Koolen Industries, as a major shareholder. “He’s a seasoned venture capitalist and is advising us on these issues.”

“Our device will very quickly be able to compete with separate devices for energy storage and hydrogen production”

Fruitful alliance

TU Delft has invested in Battolyser Systems via Delft Enterprises and is remaining closely involved in the spin-off. It is a fruitful alliance for both parties. “At Delft Enterprises, they have a lot of experience in start-ups and the issues they face, which they can translate into advice for us”, says Slee. “They are part of our Board of Commissioners and, as shareholders, they see to it that their investment thrives.” But financial gain is only part of the story: “The Battolyser will enable TU Delft to make a very concrete contribution to the energy transition.” In other words: impact for a better society, as the university's mission states.

Mulder and Slee are very optimistic about the Battolyser's prospects. “Everyone is determined to make it work. Our company, TU Delft and also the government. The Netherlands wants to play an important role in the energy transition, but we don’t yet have any companies that manufacture electrolysers in the Netherlands. We’re helping to plug that gap”, says Slee.

He also envisages opportunities outside the Netherlands. Mulder: “Our device will very quickly be able to compete with separate devices for energy storage and hydrogen production, which also require materials that are difficult to source. This has potential on a global scale. The whole world actually faces the same problem. Wind and solar energy farms will struggle to use the energy they generate on a daily basis. If you want to accelerate the energy transition, you need to resolve that increasing demand for storage. This is a key to the energy transition that we never had before.”

The Battolyser also does that in a unique way. “The Battolyser not only allows you to store the surplus and sell it at a time that’s favourable, you can also serve the hydrogen market in the process,” says Mulder. Slee: “It’s an unusual combination of a battery that never gets full and an electrolyser that can switch just as quickly as a battery. This is the first time that fluctuating renewable electricity generation can be linked economically to society's energy demand."