Imagine this: you can control the acoustics of your environment, no matter the size and shape of the space around you, your access to electricity, and the type of sound you’d like to control. That is what the ADAM project prototype offers. With the use of mathematical models and 3D printing, amongst others, ADAM allows the creation of tailor made sound absorbers.

The sound absorbers of the prototype make us of the principle of Passive Destructive Interference (PDI). According to PDI, interfering sound waves that are in counter-phase are self-cancelled. To achieve this self-cancellation, series of tubes in varying lengths and diameters are used. As a result, the acoustic performance of ADAM is strongly related to its predefined geometrical characteristics, and can be easily customised to meet specific requirements.

“As function mixes and open or hybrid uses of spaces are happening more frequently, it’s important to find highly customisable solutions to target specific frequencies of noise nuisance,” explains researcher Arjan van Timmeren. Current solutions for sound absorption have strong limitations. They mostly rely on commonly available standard materials; they are typically produced in simple forms and are mostly applied in a later stage of the design process. As a result, current solutions for sound absorption offer valuable solutions, though in general limited possibilities for customisation, which is crucial in effectively providing solutions with optimised performance.

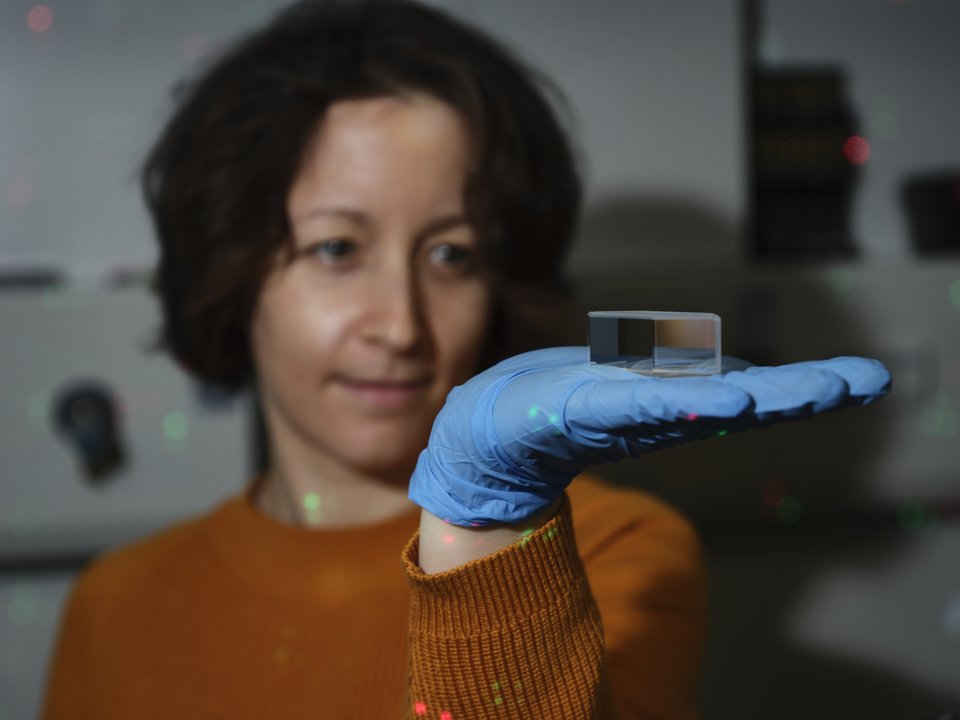

The research project is the first to explore passive destructive interference sound absorbers in combination with additive manufacturing in a high level of detail. “We developed a digital workflow where designers, architects, and engineers can actually craft acoustics and develop components that are optimised for acoustic performance,” explains researcher Foteini Setaki. Researcher Martin Tenpierik continues: “By combining different quarter wavelength tubes, we can achieve broad spectrum sound absorption in one product.” The resulting parametric tool for performance-driven design makes use of a mathematical model, validated and specifically finetuned for 3D printing. Researcher Michela Turrin: “The resulting designs are produced by use of additive manufacturing. This allows the production of a large variety of complex shapes, not necessarily based on industrial size and repetition.”

Collaboration with practice

The multidisciplinary research team from the faculty of Architecture and the Built Environment connects the fields of Environmental Technology & Design, Building Physics & Services, and Design Informatics. The additional collaboration with industry partners created the vital knowledge exchange to develop the new techniques. Amongst others, acoustic consultancy firm Peutz opened up their testing facilities, and Belgian company Materialise helped develop the novel 3D printing techniques. With the development of the prototype within the NWO Open Technology programme, this type of collaboration is exactly what is needed, according to senior programme officer Erwin Onderwijk: “This project has really brought researchers and end users together.”

What’s next?

“The results are really promising, especially when it comes to lower frequencies and the reduced thickness of the applied materials,” says researcher Foteini Setaki. “We are hoping that we will be able, very soon, to launch a ready product that can enter the construction industry market.” Although the product has originally been developed for the building industry, other sectors have already expressed interest. The highly customisable nature of ADAM has garnered the attention of manufacturers of aircrafts, trains, and cars. The tailormade elements of ADAM can offer the desired acoustic control in the close confines of such transporation modes. The research team is currently in the process of upscaling the prototype and welcomes additional collaborations.

More information

Contact Arjan van Timmeren, Martin Tenpierik, or Michela Turrin for more information about the project and possible collaborations.