From CO2 to plastics and laptops

Next to the generating power and heat, fossil fuels (hydrocarbons) also serve as feedstocks in all kinds of industrial processes, ultimately providing society with plastics, laptops, televisions – tangible things that can’t be made with green electricity alone. CO2 conversion by means of electrocatalysis is where renewable energy meets renewable feedstocks meets CO2 emission reduction.

‘Our world is based on carbon,’ says Tom Burdyny. ‘And the only way to replace carbon renewably is by converting captured CO2.’ One way to do that is the so-called reverse water-gas-shift reaction, in which CO2 and hydrogen are converted into carbon monoxide and water. You can then use carbon monoxide and hydrogen to create a large variety of hydrocarbons and compounds containing oxygen. But this is not as good a solution as industry would want. Electrocatalytic conversion of CO2 is a promising alternative in that it allows the direct production of multi-carbon compounds such as ethylene. It is also a process that takes place at a much lower temperature, allowing it to be turned on and off. Though certainly promising, Tom is careful about raising expectations: ‘CO2-electrocatalysis could be better, and we don’t know yet if it’s more viable than the current standard.’

Base chemicals

The energy transition has always been the background of Tom’s research. But having been educated in mechanical engineering, it was not until midway through his PhD that his interest in energy shifted to technology that is more chemical engineering in nature. ‘When I came across electrocatalysis, I thought this to be technology with the potential to scale up to levels which could impact global energy systems. It then turned out that my non-chemical background gave my research a fresh perspective.’ As an assistant professor in chemical engineering, he now has his own research lab. It houses just under ten PhD’s and postdocs and several MSc students on top of that. In their research, they take an electrochemical engineering approach towards converting CO2 directly into base chemicals. ‘We focus on electrolysers for the production of carbon monoxide and ethylene – products that have a large global market and can thus impact CO2 emissions.’

The only way to replace carbon renewably is by converting captured CO2.

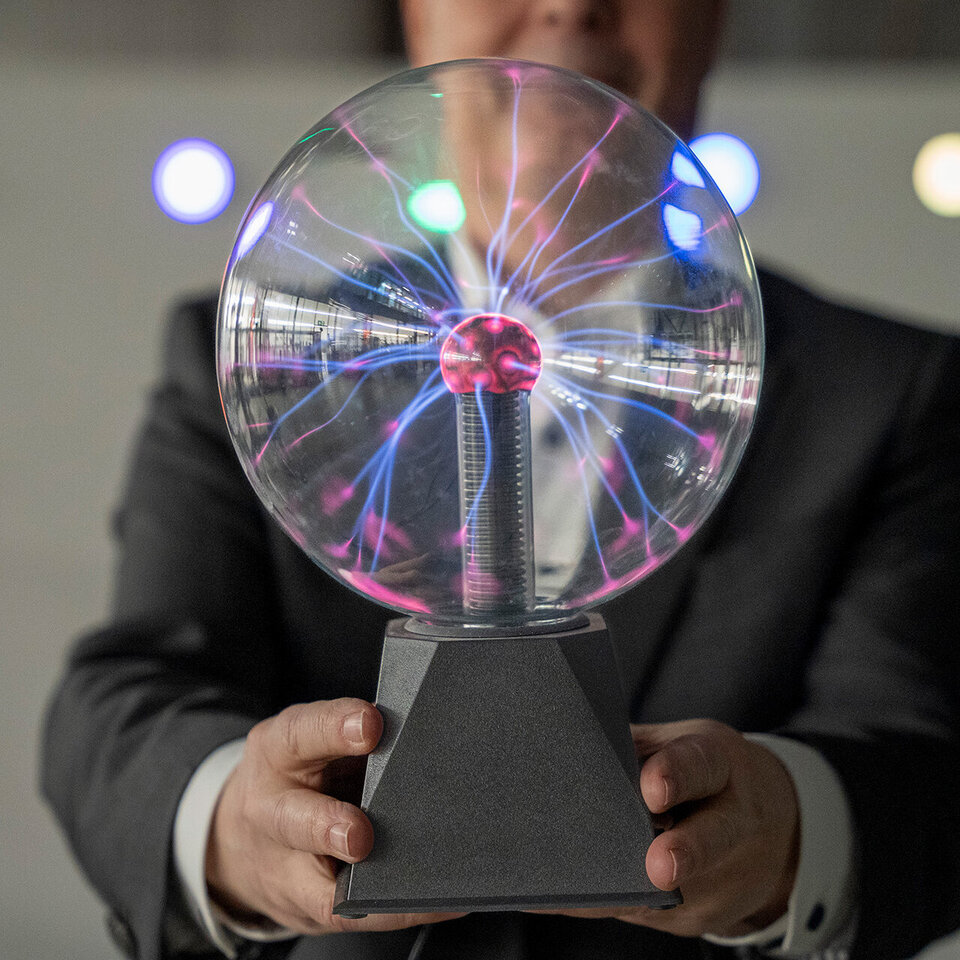

Infrared

A recent breakthrough in his lab was somewhat of a chance discovery, related to inevitable heat losses – putting in 100 units of electricity will never yield 100 units worth of reaction products. Tom: ‘We had a very high-end infrared camera lying around which we aimed at the back of our electrolyser. We then saw some things we didn’t expect. Digging into it, we found that the observed effects were directly related to the reactions that were ongoing. In our lab, we now use infra-red imaging as a very applied research tool – where do we see points of failure in our system – as well as for helping to answer very fundamental research questions. We can monitor local efficiency, local reactions, in both time and space.’

Showstoppers are welcome

Of course, Tom is aiming for electrocatalysis to become a key enabler of the energy transition. But he is also open to the idea that it might not succeed. He is, in fact, actively looking for showstoppers. ‘In my research I want to define all the big problems with this technology. And then either figure out an engineering solution or be able to say: “these problems will never be overcome, we should stop doing this research and direct our attention elsewhere.”’ One of the open questions is how well or poor electrolysers will work on green energy which, because of its nature, may only be available intermittently. ‘Ruud van Ommen and I are starting a project next month on such flexible operation. We may find that intermittent operation isn’t possible, or that some buffering is required to maintain good performance. There are many aspects to explore in this project.’

Infrared imaging allows us to monitor electrochemical reactions in both time and space.

Upstream and downstream

Part of what attracted Tom to join TU Delft is the e-Refinery institute. When it was established four years ago, it was unique in the world in that it fosters integrated electrochemical research covering all length scales – from nanometres (how do reactions progress at the atomic level) to the scale of kilometres (transport of CO2). Tom: ‘It makes a very big difference to have these experts down the hall. We interact at least once every couple of weeks, providing real-time suggestions.” It is also why his lab houses two classes of research. “On the one hand, we focus on the absolute best performance of our CO2-electrolysers. But most of our research is aimed at understanding the inner workings of the technology. We can then understand the trade-offs of this technology when considering upstream or downstream processes, such as purification and separation steps.’

No “I” in success

Whether in research or in a classroom, Tom really wants to inspire people. ‘Even if I myself don’t accomplish anything revolutionary that meaningfully affects the energy transition, I really want the people that I mentor to go on and do things that make a difference.’ It is certainly a mentality that helped him to become Best Lecturer of TU Delft of 2021. It is also why he initiated, and chairs, the upcoming e-Refinery symposium. ‘The vast majority of current PhDs have started during COVID times. They haven’t yet had much chance to interact in person outside of their own groups. The symposium also allows everyone to (re)connect with industry, to give them a flavour of our ongoing research and to have more knowledgeable discussions about the way forward.’ The symposium caters to all expertise required to make electrocatalysis a success – chemical engineering, physics, fluid dynamics, process technology, policy and management. Tom: ‘Some expertise we don’t yet have in e-Refinery. So, do consider yourself cordially invited!’

We want to know the trade-offs of electrocatalysis when considering upstream and downstream processes.

The e-Refinery symposium takes place on March 14 and 15 in Delft. You can read more about the program here. For press requests regarding the symposium, please contact Dave Boomkens at D.J.Boomkens@tudelft.nl.

CO2 electrocatalysis

From a thermodynamic perspective, CO2 is down at the bottom: you need to add energy to convert it into something useful. Electrocatalysis is a very clean way to do just that. All that is needed is CO2, water, and green energy. And a catalyst, of course – a material that increases the chemical reaction rate, reduces energy losses and is itself not consumed in the process. Copper is the catalyst when converting CO2 – captured from flue gasses or the atmosphere – into (complex) hydrocarbons.