Current coolant gases from air conditioners and fridges either contribute a significant amount to global warming, or otherwise they are dangerous to use. Bowei Huang and Michael Maschek from the Delft company Magneto are working on a safe and environmental friendly alternative for cooling: a unique solid material for heat pumps.

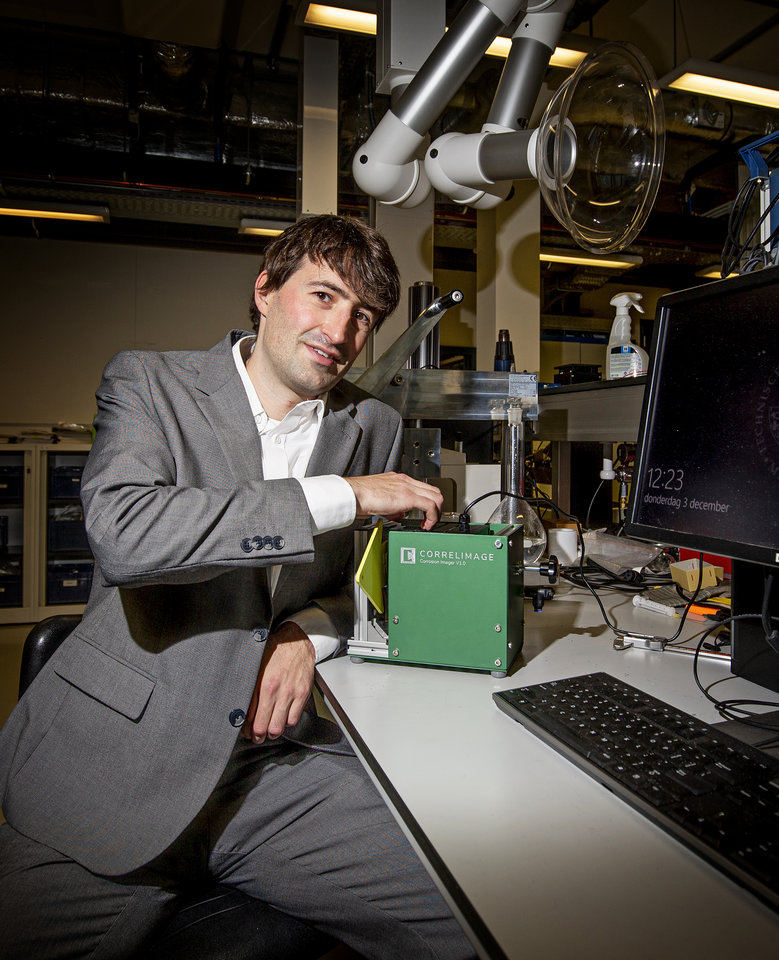

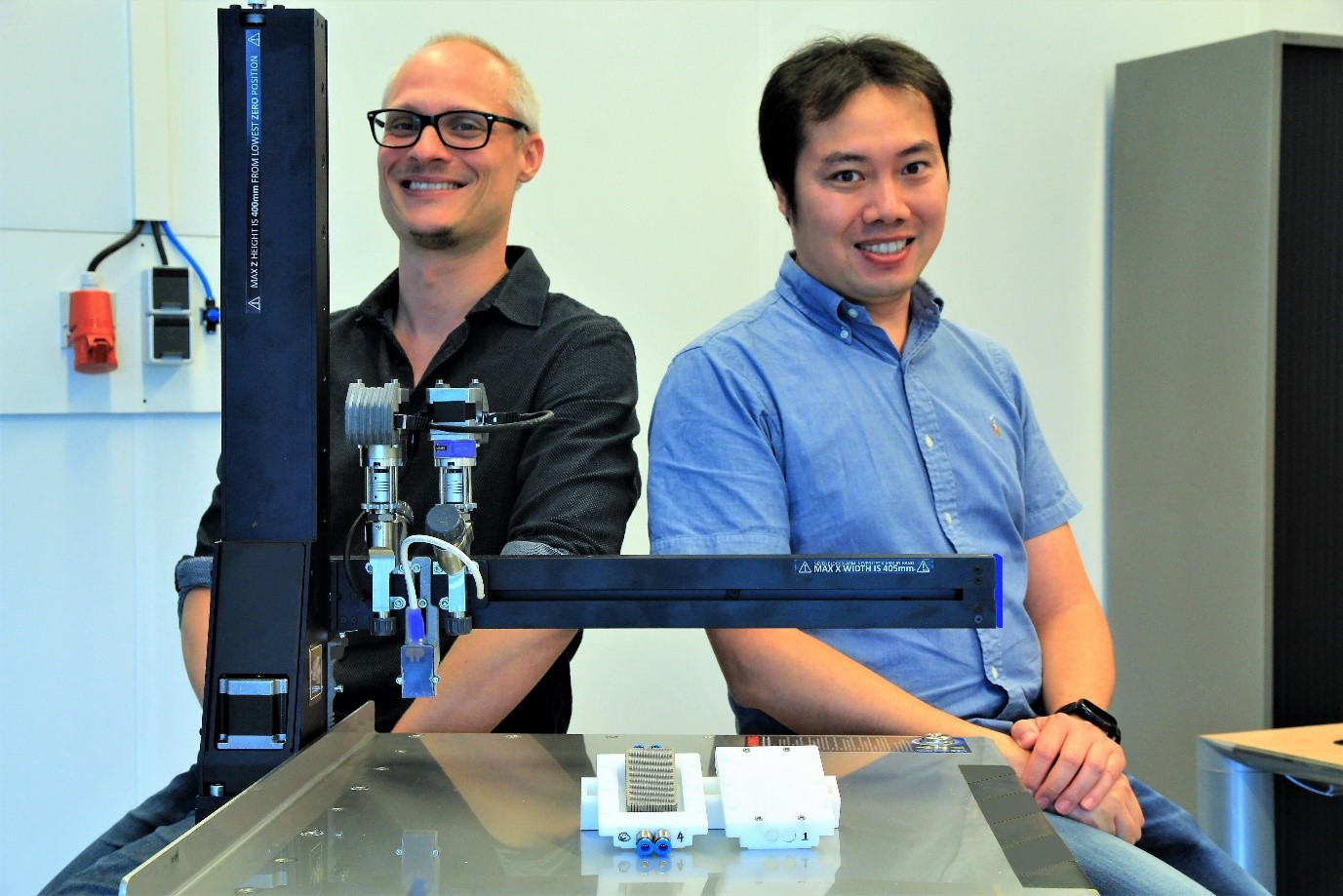

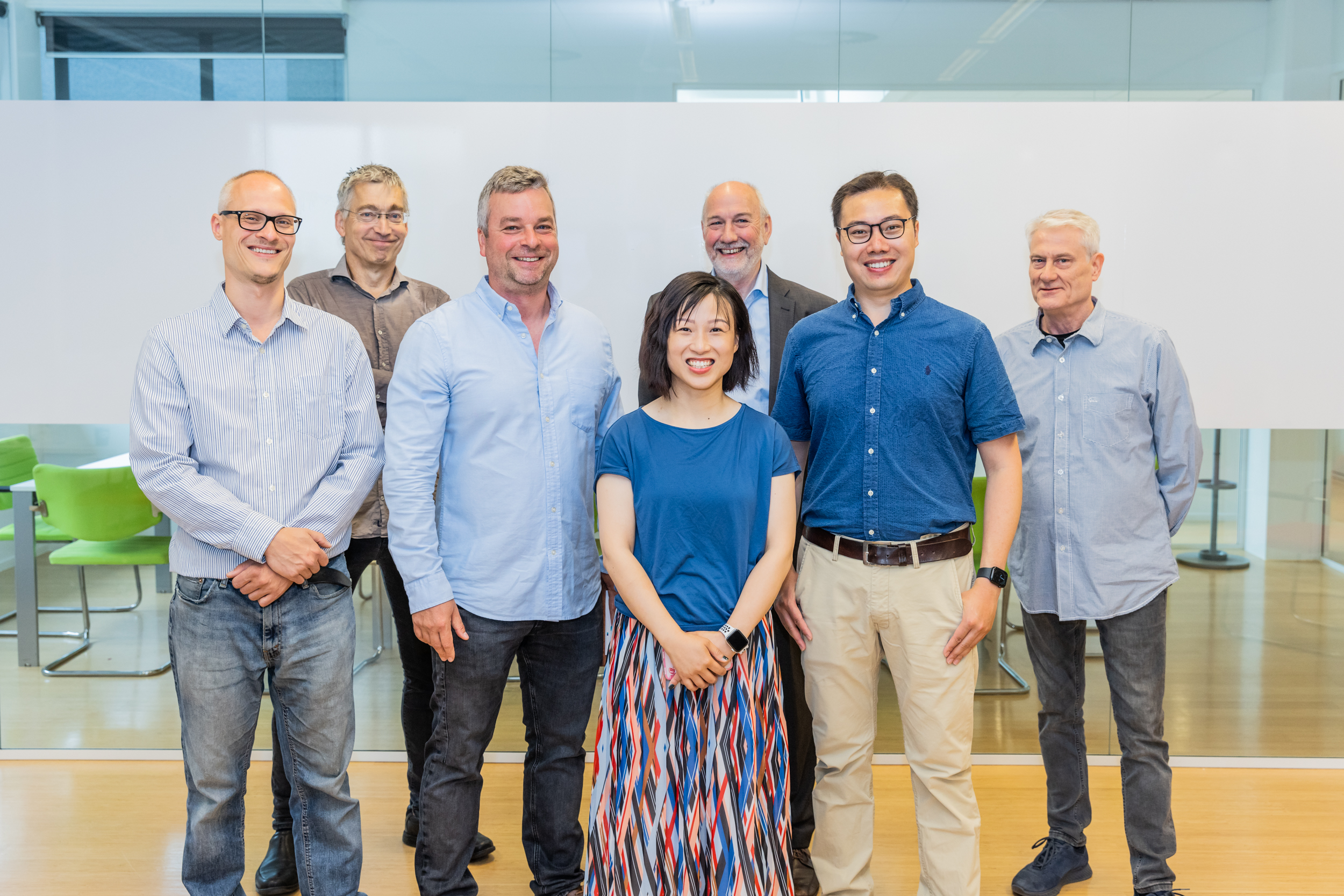

Bowei Huang, a mechatronic engineer by training, and Michael Maschek, a material scientist, co-founded Magneto – a TU Delft spin-off – in 2019. “When we think about global warming, we think about transportation, such as cars, or fossil fuel power plants,” says Maschek. “But more than 10 percent of global warming actually comes from energy consumption of cooling systems and refrigerant gases that leak from fridges and air-conditioners into the atmosphere. For cooling alone, that is more than three times the contribution of aviation and shipping combined.”

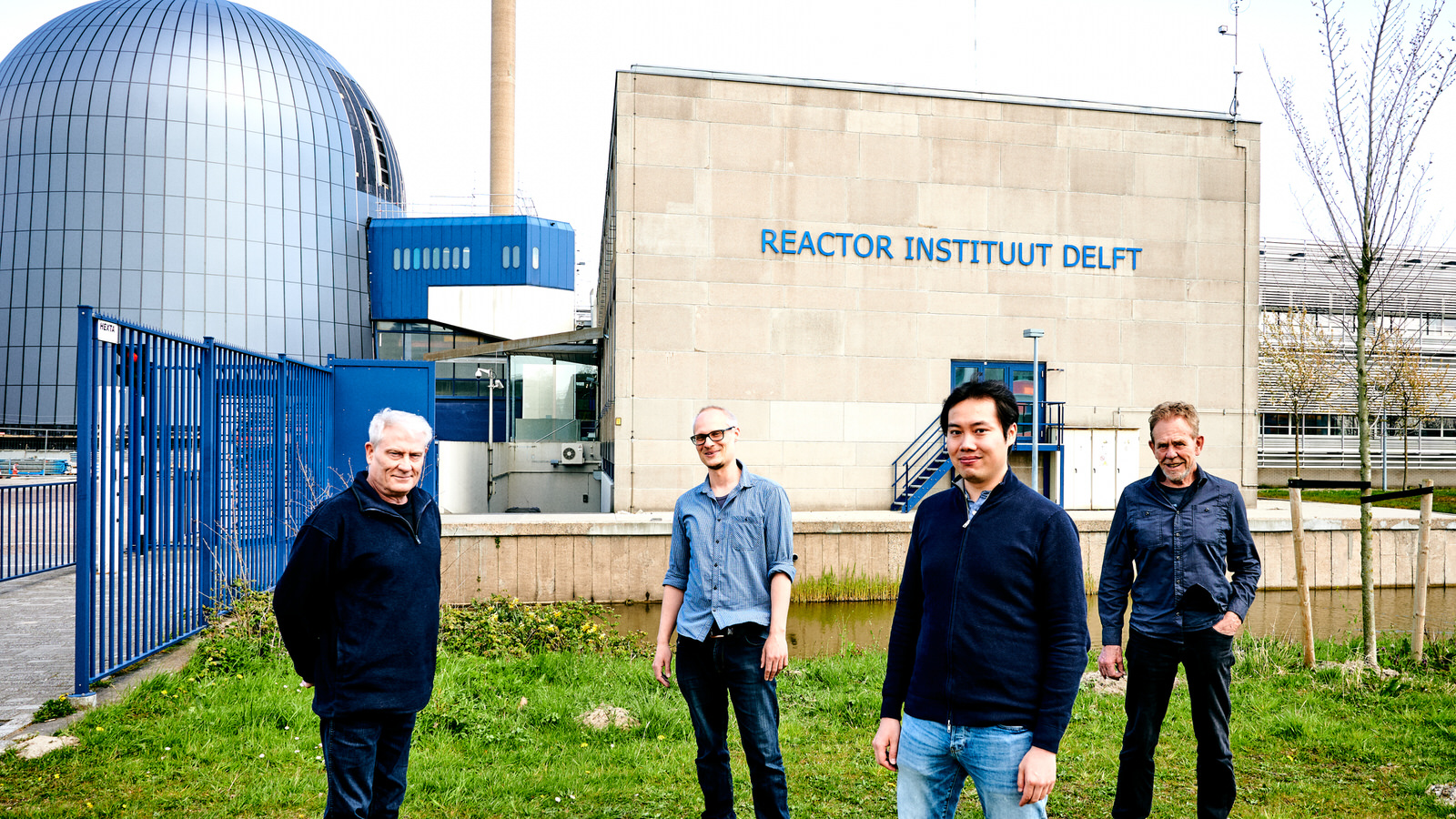

Huang and Maschek met in the FAME group at the Radiation, Science and Technology (RST) department of TU Delft Reactor Institute, where they investigated magnetic heating and cooling. “We offer an alternative to refrigerant gases that is a solid material, so it has no global warming effect and there is no high pressure, so no danger,” Maschek says.” Former PhD-student Huang: “I chose to work in the field of magnetic cooling because I believed that this cutting edge technology can really change the world. But I realised that I couldn’t continue in academic research if I wanted to contribute to the transition towards safe and environment-friendly cooling and industrialise this technology.”

A century of dangerous coolants

A hundred years ago, the cooling industry used natural gases such as propane and ammonia as refrigerants. When it became clear that these gases put users in danger, since propane is flammable and ammonia toxic, they had to develop a new type of refrigerant gas. It was later discovered that the gases which replaced them – so-called hydrochlorofluorocarbons (HCFCs) – caused holes in the ozone layer around the earth. The current generation of hydrofluorocarbon (HCF) gas coolants, while not dangerous to people or the ozone shield, are very strong greenhouse gases; the greenhouse effect of some HCF gases can be up to 10.000 times stronger than that of CO2.

In 2016 a large number of countries agreed to jointly phase out HCFs through the Kigali amendment. Maschek: “Then the cooling industry went back to using natural gases. So instead of solving the problem, they mitigated it back to the user by putting them in danger again. Supermarkets for instance now switch to CO2 cooling installations that are under very high pressure, meaning that they could explode if there’s a defect in the piping system.”

Unique material

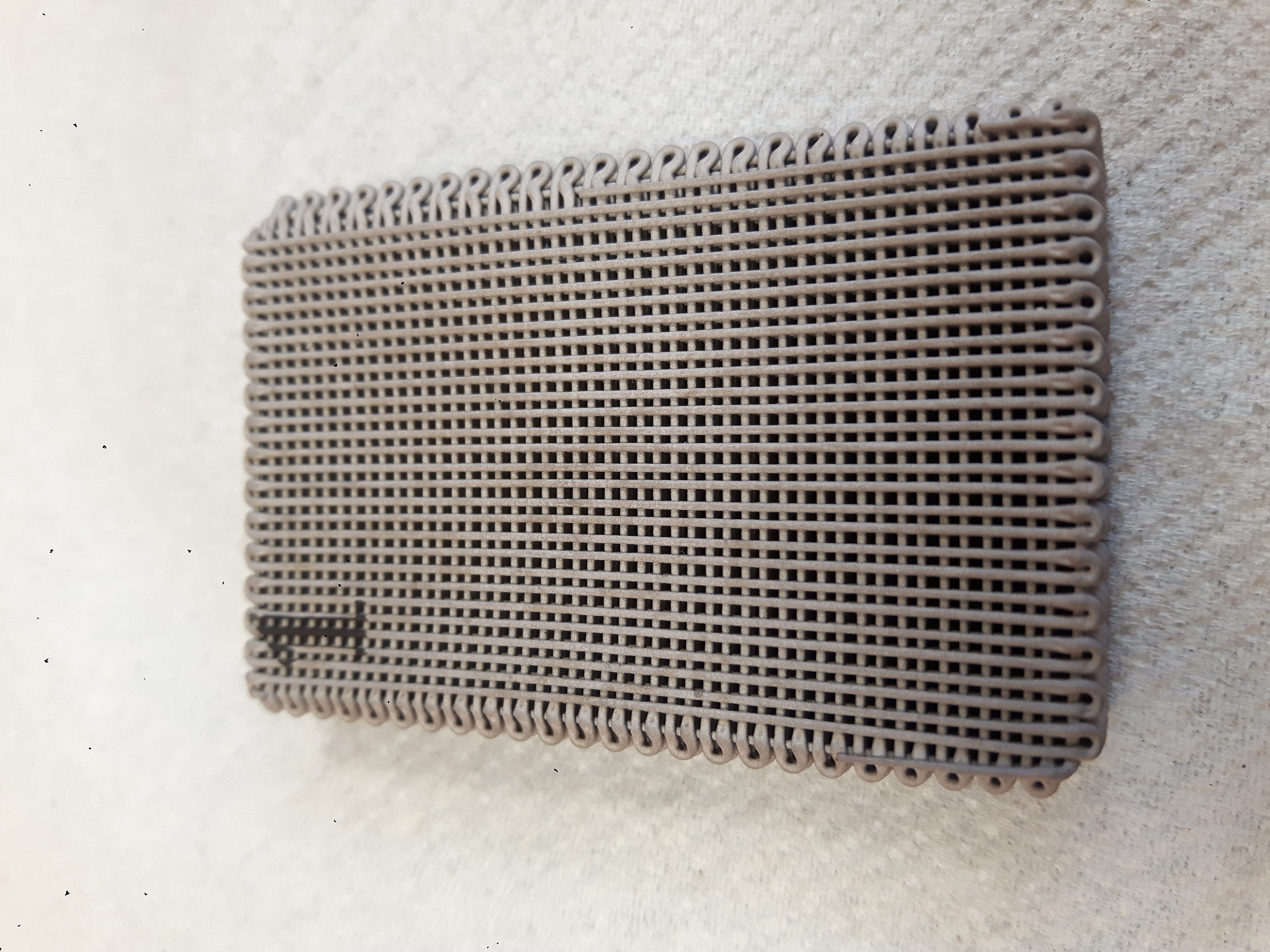

As an environmental-friendly alternative to refrigerant gases, Magneto develops a heat pump component based on a unique, so-called magnetocaloric material that was invented by professor Ekkes Brück. Maschek: “The special ability of a magnetocaloric material is that it can convert magnetic energy into heat very efficiently. We can use this magnetocaloric effect for either cooling or heating.” Their material consists of a powder that they 3D print into mesh structures. By placing the mesh structure in a rotating magnet and running water through it, they can pump heat from one place to another.

The unique feature of the company’s material is that it doesn’t contain any of the usual rare metals such as gadolinium, while it still transfers heat equally well as other heat pump materials that do contain rare-earth metals. In fact, the magnetocaloric powder can even operate in a larger temperature range than a typical heat pump substance. “Our heat pump component contains the elements manganese, iron, phosphorus and silicon – all abundantly available on earth. That’s why we don’t need to rely on the already strongly shrinking supply of rare-earth elements for our heat pump material,” says Huang.

Supermarket pilots

“We are planning to run a case study with the cooling installation contractor of one of the biggest supermarkets in the Netherlands,” says Huang. “Supermarkets have a lot of pain from the regulations on refrigerant gases and don’t want to put their customers in danger, that’s why they’re planning a pilot with our heat pump material in 2024 and 2025,” Maschek explains. “Because it’s a new technology, the purchase price of our system may be a few times higher than current installations. But if you take into account that our system consumes up to 30% less energy and requires less maintenance, the total costs over the whole lifetime of the machine will be much lower in the end.”

Magneto is also exploring the possibility to provide a cooling system for the electric vehicles of online retailers and food transporters of cold chains. “They are very interested in our device, because if we can save them 30% electricity, they can drive their cars 30% further and deliver to more customers.”

A mountain of knowledge

Magneto stems from a collaboration between chemical company BASF and TU Delft, through Ekkes Brück. “We build on 10 years of research from TU Delft and BASF, so we started with a mountain of knowledge about magnetocaloric materials,” says Maschek. Through start-up incubator Delft Enterprises, Maschek and Huang are still involved in the research group of Brück. They collaborate on research, the implementation of the technology and to get funding for new projects. “We always want to keep a connection with the group, because it is our knowledge base for new developments,” Huang says.

Thanks to their agreement with Brück, Magneto can make use of a magnetic and X-ray measuring device at the RST at a special start-up rate. With these two instruments, they can find out if a material is suitable for application and what the quality of a material is. “Since we are a Deep-Tech company, we need a lot of expensive machines to evaluate very basic physical, chemical and structural properties of the materials. So we have to use the money wisely, and it helps to use these devices from TU Delft as a service,” Maschek says.

Dream house

With their first investment that Magneto received earlier this year, Huang and Maschek are creating a plug-and-play heat pump component that contains the unique 3D-printed material. Their next goal: a heat pump prototype. “Ultimately, our dream is to have the whole value chain in-house at Magneto, so that we have all the know-how and can make sure that our product is safe and that it is eventually customisable for all applications,” Huang says.

Maschek envisions a dream house which uses just a magnetocaloric heat pump. “Instead of using three different types of devices such as a boiler, heat pump and air conditioning, residents could heat and cool the house with one device, easily switching from heating in winter to air conditioning in summer.” This device could work silently, Huang explains: “Normally, compressors make a very high-pitched sound to compress gas into liquid. But our machine only has a rotating magnet and a water pump, so in principle we can make it very quiet. So you don’t need to put a big installation outside your house.”

Magneto B.V.

Molengraaffsingel 10

2629 JD Delft

Nederland

Website: https://magneto.systems/

E-mail: info@magneto.systems

Header image:

The Magneto material on atomic scale, the colours represent the electron distribution.

Meer verhalen

Current coolant gases from air conditioners and fridges either contribute a significant amount to global warming, or otherwise they are dangerous to use. Bowei Huang and Michael Maschek from the Delft company Magneto are working on a safe and environmental friendly alternative for cooling: a unique solid material for heat pumps.