Algae replace chromium-6?

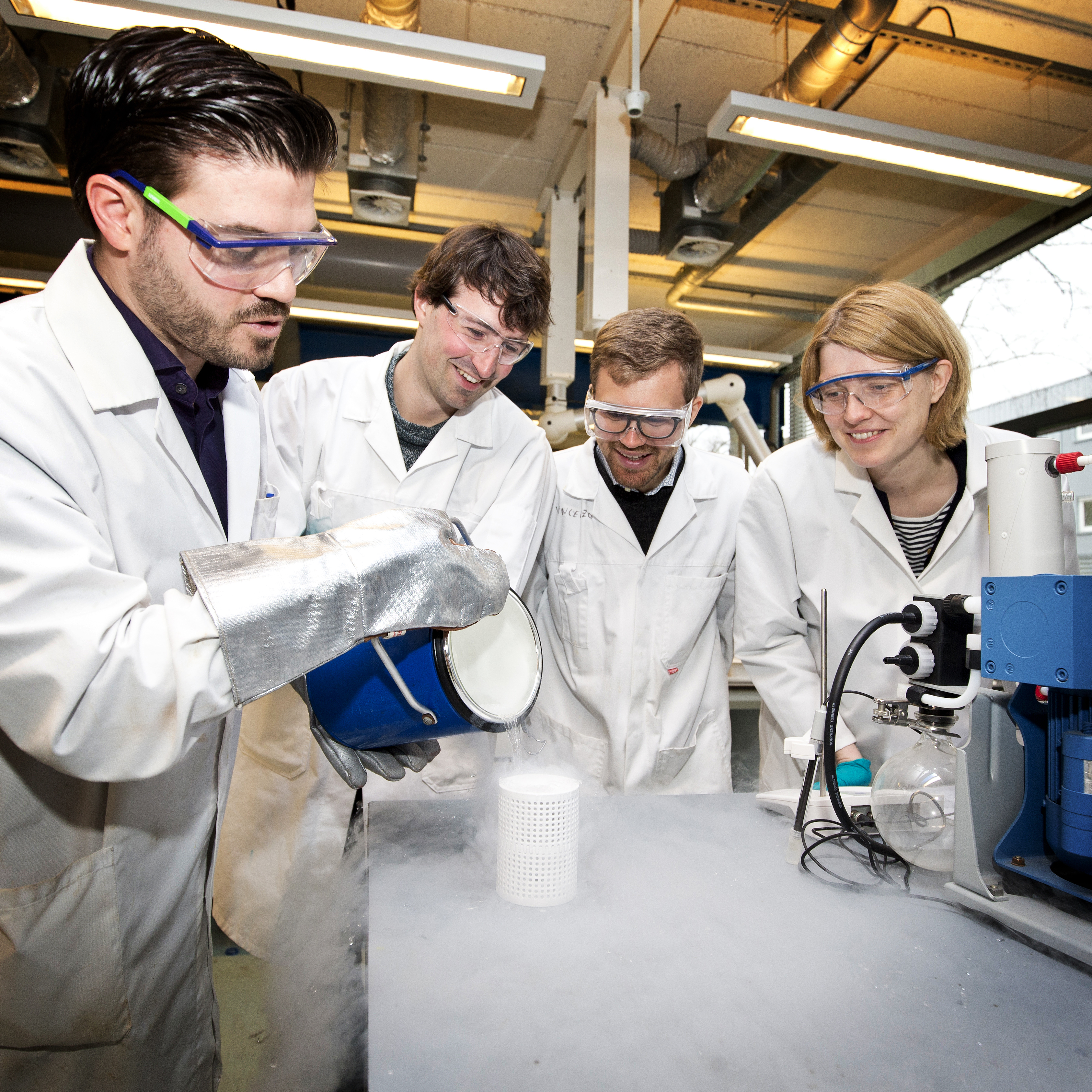

Extraordinary things are happening in Dr. Santiago Garcia’s laboratory at the Faculty of Aerospace Engineering. His research group is working on new solutions for existing problems in the field of aircraft materials. The group is currently achieving great success using algae in the development of a safe and environmentally friendly corrosion protector to replace the carcinogenic chromium-6.

The European Union is determined to see chromium-6 banned from all chemical processes as quickly as possible. This is why many scientists are looking for alternatives. Unfortunately, preventing corrosion without chromium-6 is proving to be far from easy. This is especially the case in vehicles, such as aircraft, that have to withstand extreme conditions that fluctuate quickly.

Support this research

With your support an algae nursery can be built in Delft and the research for an environmentally friendly replacement for chromium-6 be accelerated.

Donate yearly Donate onceAlgae skeletons

This is why Santiago Garcia is pursuing a completely different route: he is placing the skeletons of algae into his coatings. These exoskeletons of unicellular diatoms are excellent carriers of corrosion inhibitors. Corrosion inhibitors are salts that react with the metal surface when it is damaged, forming a protective layer.

“Unlike with chromium-6, we cannot process most alternative - safe and environmentally friendly - corrosion protectors in the coating straight away, because they react with it and affect its properties,” explains Garcia. “They therefore need to be isolated. This can be achieved by using diatoms that have an external skeleton made from silicon dioxide. Although the algae exoskeletons come in all kinds of different shapes and sizes, they are almost all hollow with nanoporous walls and can therefore be filled with an inhibitor. This is only released if the coating is damaged.”

100 percent biologic

Using the algae exoskeletons has significant advantages. Algae are a cheap renewable raw material and 100% biologic. In the lab, they appear to do the job – all scratches are well protected. But according to Garcia, industrial tests are a different story. “All alternatives have to pass the same tests as chromium-6. This often proves to be difficult – there are good reasons why chromium-6 has been used for a century despite its great dangers.” The ultimate aim is to test the coating in a real aircraft. “It can be done on a small panel, as long as we can see how it functions in practice and prove that it really works.”

Nursery

Algae skeletons are currently obtained as a residual product while mining for other raw materials. Many different types are delivered together, and the skeletons are mostly broken. There are 100,000 different types, which makes it difficult to obtain the type you want intact. But the solution to this is actually quite simple: an algae nursery in Delft. “What we now need is the right type, in the right quantities, when the research calls for it,” says Garcia.