Fully Integrated MEMS TGA Device for Nano-Mass inspection

Thermogravimetric analysis (TGA) is commonly employed to determine degradation temperatures, absorbed moisture content or level of inorganic and organic components in milligram amount of materials. When such amounts of sample material are too dangerous to handle, as in the study of the decomposition point of explosives, or are not available, as in forensic investigation, MEMS TGA devices are a valuable option.

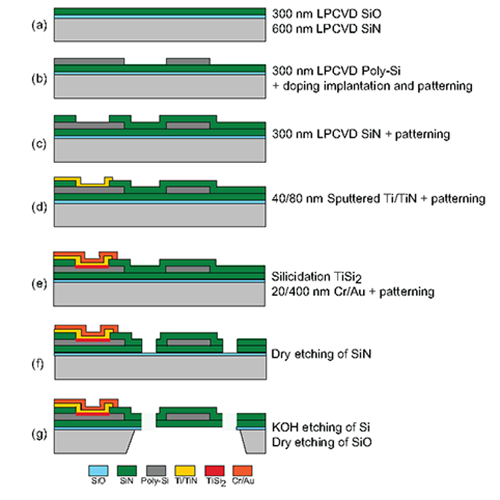

To realize a MEMS TGA device a number of challenges arise, in particular: the decoupling of the sample mass and temperature dependence of the resonance frequency of the device; the integration of a heater, a temperature sensor, an actuator and a sensing element on the device; the mass and the temperature calibration of the device.

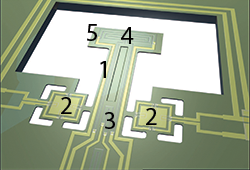

3D-Drawing of theTGA device.

(1)The cantilever is connected through SiN tethers to (2) the thermal actuators.(3)Piezo resistors in Wheatstone bridge configuration are used to sense the resonance frequency. The hot junction of the (4) thermocouple and (5) the heater are on the paddle.