In situ consolidation of thermoplastics

Themes: Aerospace, Materials

Late lab scale demonstration

A TRL is a measure to indicate the matureness of a developing technology. When an innovative idea is discovered it is often not directly suitable for application. Usually such novel idea is subjected to further experimentation, testing and prototyping before it can be implemented. The image below shows how to read TRL’s to categorise the innovative ideas.

Why?

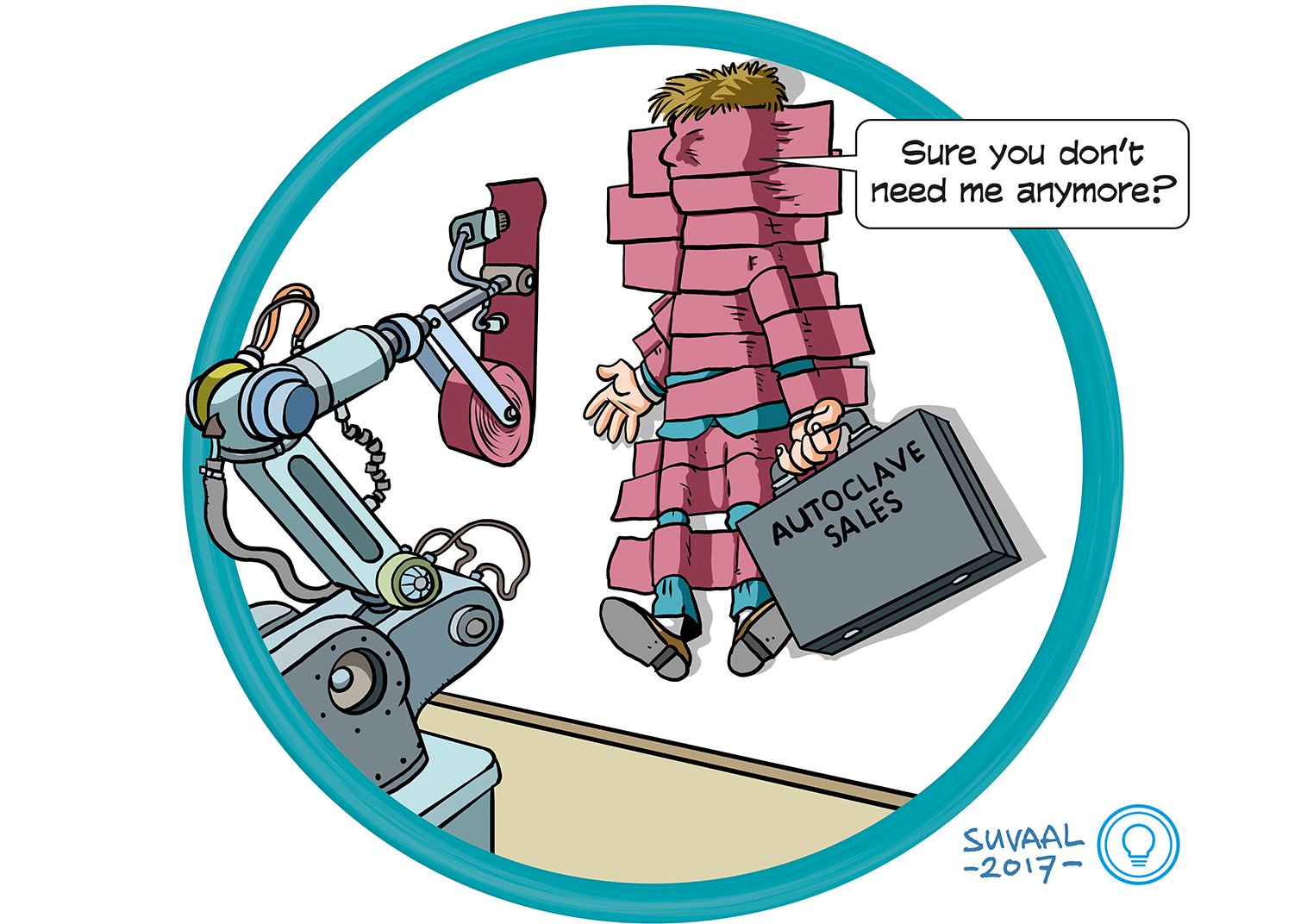

Production of composite thermoplastics currently requires consolidation in an autoclave. In situ consolidation eliminates this requirement. This reduces product size restrictions, shortens production time, increases production process flexibility, and significantly reduces energy consumption.

How?

A robotic arm is fitted with a laser-heater-assisted fibre placement head to locally heat and pressurise (consolidate) the composite layers. Measurement systems check the quality of the part as it is being produced.

When?

With experiments we characterise the effect of production process parameters and the products’ macroscopic properties. In several years time this will lead to reliable simulation software ready for industrial application.

Dr. ir. Sonell Shroff