Gentle Driving of Piles

Research Themes: Energy, Structural Engineering, Water & Maritime

A TRL is a measure to indicate the matureness of a developing technology. When an innovative idea is discovered it is often not directly suitable for application. Usually such novel idea is subjected to further experimentation, testing and prototyping before it can be implemented. The image below shows how to read TRL’s to categorise the innovative ideas.

Summary of the project

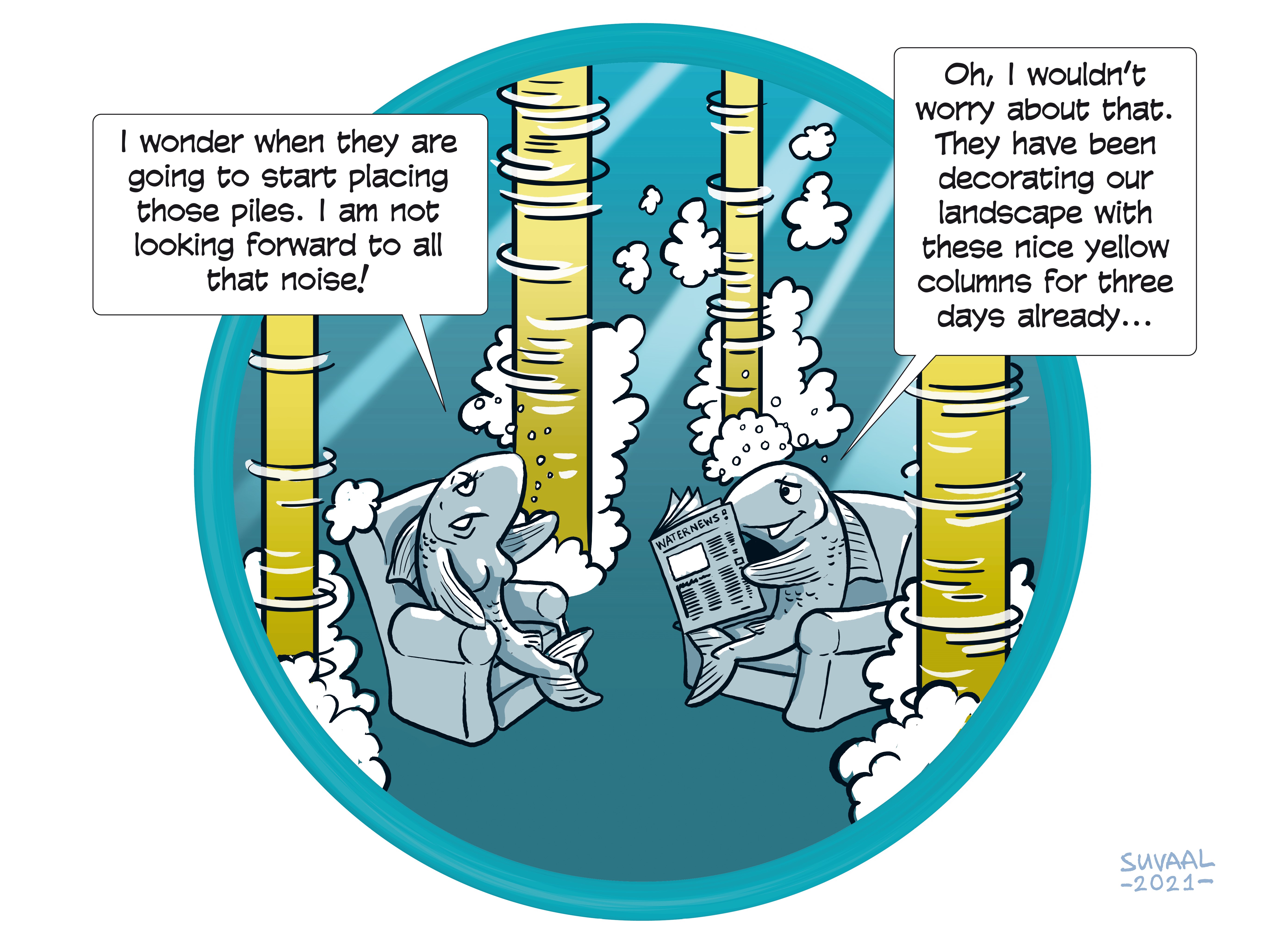

Currently we drive monopiles – huge long steel structures - into the ocean floor for the foundation of wind turbines at sea. A huge undertaking where long steel cylinders are usually driven down by knocking at the top. New technologies have been developed where these piles are driven in the ground by shaking them vertically. This still produces quite some noise and once in a while the pile gets stuck before reaching the desired penetration depth. Within this project a novel method for driving piles is developed inspired by how we open champagne bottles – twisting the cork before it tops. This method still uses a shaker for making the pile vibrate. However, not only does it vibrates vertically, but also a torsional motion is excited at a much higher frequency. This new shaker has been demonstrated to drive the piles smoothly and quickly.

This new method for driving piles also reduces the underwater noise emitted during pile driving as torsional vibrations emit very little noise into water.

What's next?

As the next step the novel shaker is being up scaled for XXL monopiles. This is done by implementing new engineering solutions, which have never been used in pile driving in the past. In parallel, a sensor is being developed which will go onto the pile in order to automatically determine the amplitude and frequency for each of the two directions of motion for the shaker. Subsequently, research will be conducted to make this sensor contactless and drone-based.

Contribution to the Energy transition?

This method for driving piles will increase the installation speed of piles as it is more efficient. Importantly also is that the same method can be used for removing the piles without disturbing the soil too much. Finally, of ultimate importance is that this pile driving method is more environmentally friendly than the conventional methods as it emits much less noise into water. This removes the necessity to employ very costly noise mitigation measures as the environmental impact of this driving method is expected to be within the allowable limits without any additional mitigation.

Prof. dr. Andrei Metrikine

Dr. Ahmed Elkadi

subcontracted from Deltares

Dr. Federico Pisano

Mr. Evangelos Kementzetzidis

Mr. Rob Atkinson

subcontracted from DOT

Dr. Maxim Segeren

Dr. Faraz Tehrani

subcontracted from Deltares

Mr. Athanasios Tsetas

Mr. Peter de Vries

Dr. Apostolos Tsouvalas

Dr. Sergio S. Gómez

Mr. Timo Molenkamp

Mr. Kees van Beek

Faculties involved

- CEG