Omnivisi

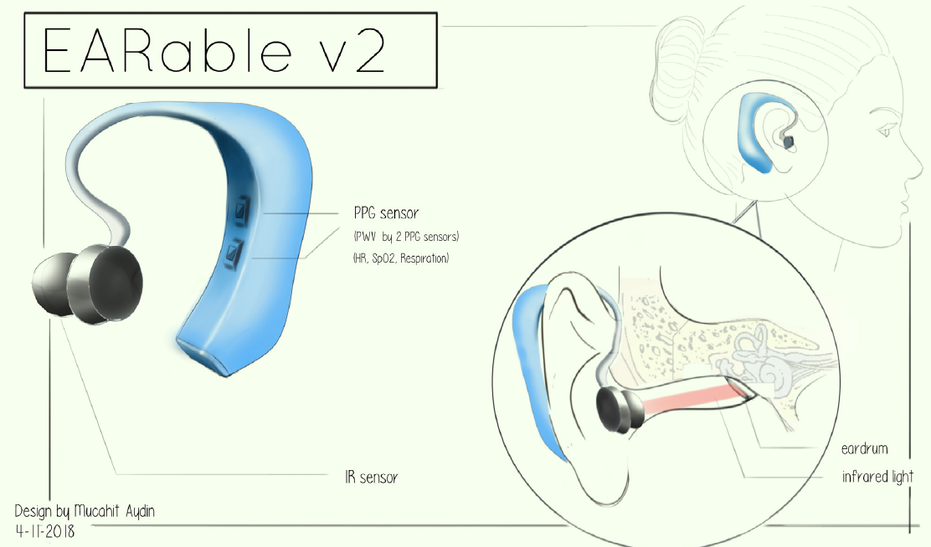

Earable with the capacity to continuously monitor all vital signs of patients

Omnivisi is a wearable which is developed in cooperation with the department of surgery of the Maasstad Ziekenhuis in Rotterdam. Its purpose is to continuously monitor all five vital signs of patients in an unobtrusive way.

Healthcare faces many challenges due to societal changes, such as aging population and increase of people with chronological diseases. Due to this, the costs of care have significantly increased over the years. In order to tackle some of these challenges, new methods should be used to increase work-efficiency, reduce costs of care and still maintain quality of life of patients.

In order to assess the health condition of patients, nurses measure their vital signs three times a day. In the current situation these measurements are taken manually and in-house research showed that this takes 2,5 to 3 hours per day per nurse.

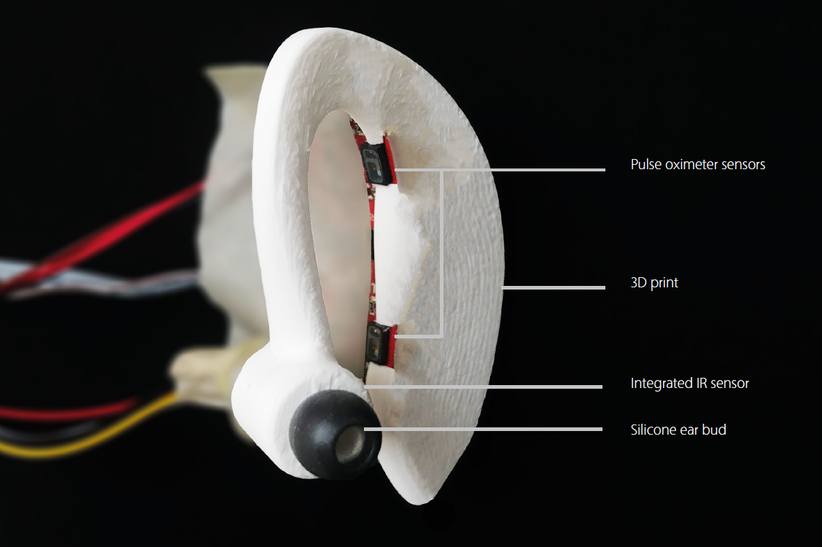

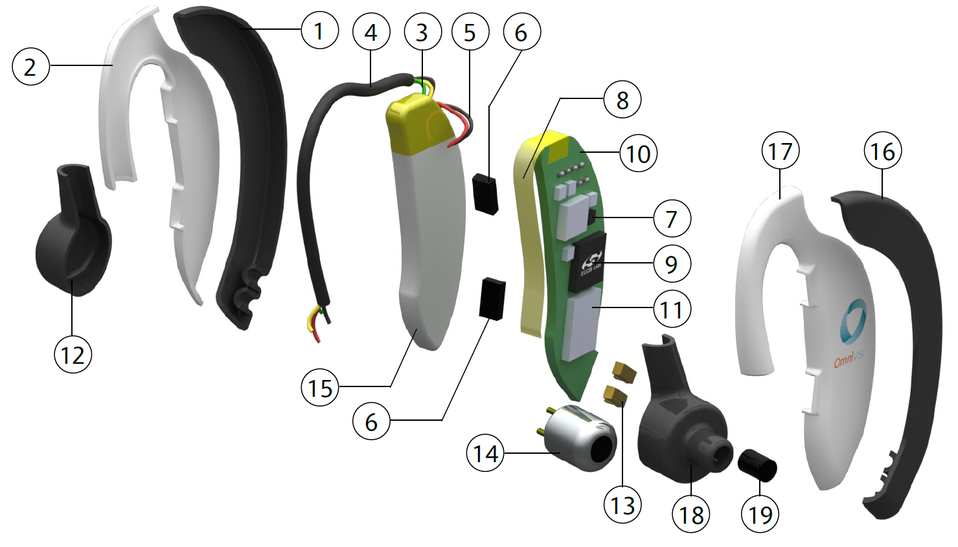

Therefore the main focus of this project was to design and develop an novel e-health device that can measure and monitor all five vital signs, i.e. heart rate, blood oxygen level, respiration rate, blood pressure and temperature. Additional requirements were that the device should be reliable, simple to use for both patients and staff and unobtrusive for the patients.

Design Process

During the design process five different concepts were proposed, including devices fitting on the ear, upper arm, wrist or fingertip. One of the major design problems was the determination of the most suitable sensor location. Nonobtrusive measurements of the tympanic temperature can only be done under the armpit or inside the ear, whereas blood pressure is usually measured with a cuff on the upper arm.

The solution was found by using the Pulse Wave Velocity technique which uses the difference between peak pulse onsets of tow PPG sensors (optical sensors which measure the oxygen saturation in blood and from which also the heart rate can be derived).

Kaspar Jansen

- +31 (0) 152786905

- k.m.b.jansen@tudelft.nl

-

Room B-3-170

Graduate student

- Mucahit Aydin

Supervision

- Prof. K.M.B. Jansen (chair)

- Dr. A. Albayrak (mentor)

- R. Klaassen (Maasstad Ziekenhuis Rotterdam)