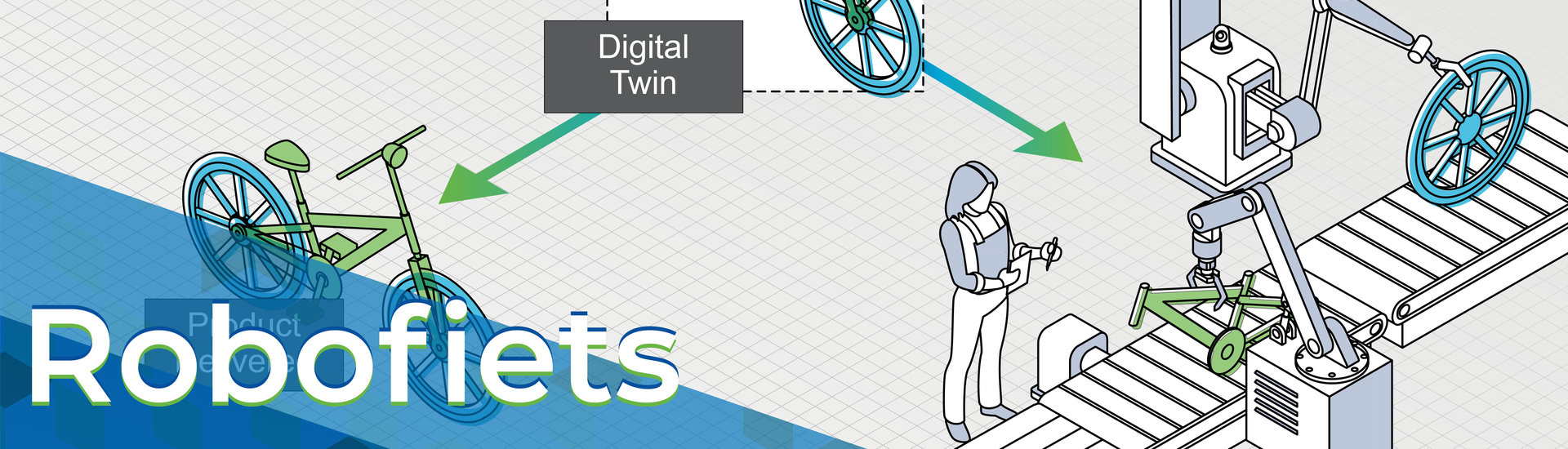

Robofiets

The Robofiets project aims to create sustainable workplaces within Europe’s bike industry by investigating the potential of assistive technologies and human-robot co-production. With the changing requirements of mass production and the introduction of new personalised cargo bikes, these technologies have the potential to help in reshoring production back to Europe. The project aims to investigate the use of robots and assistive technologies in facilitating this process and offering inclusive and sustainable workplaces for employees, especially elderly workers and workers with disabilities.

Reshoring production facilities in Europe by enabling personalised one-off production

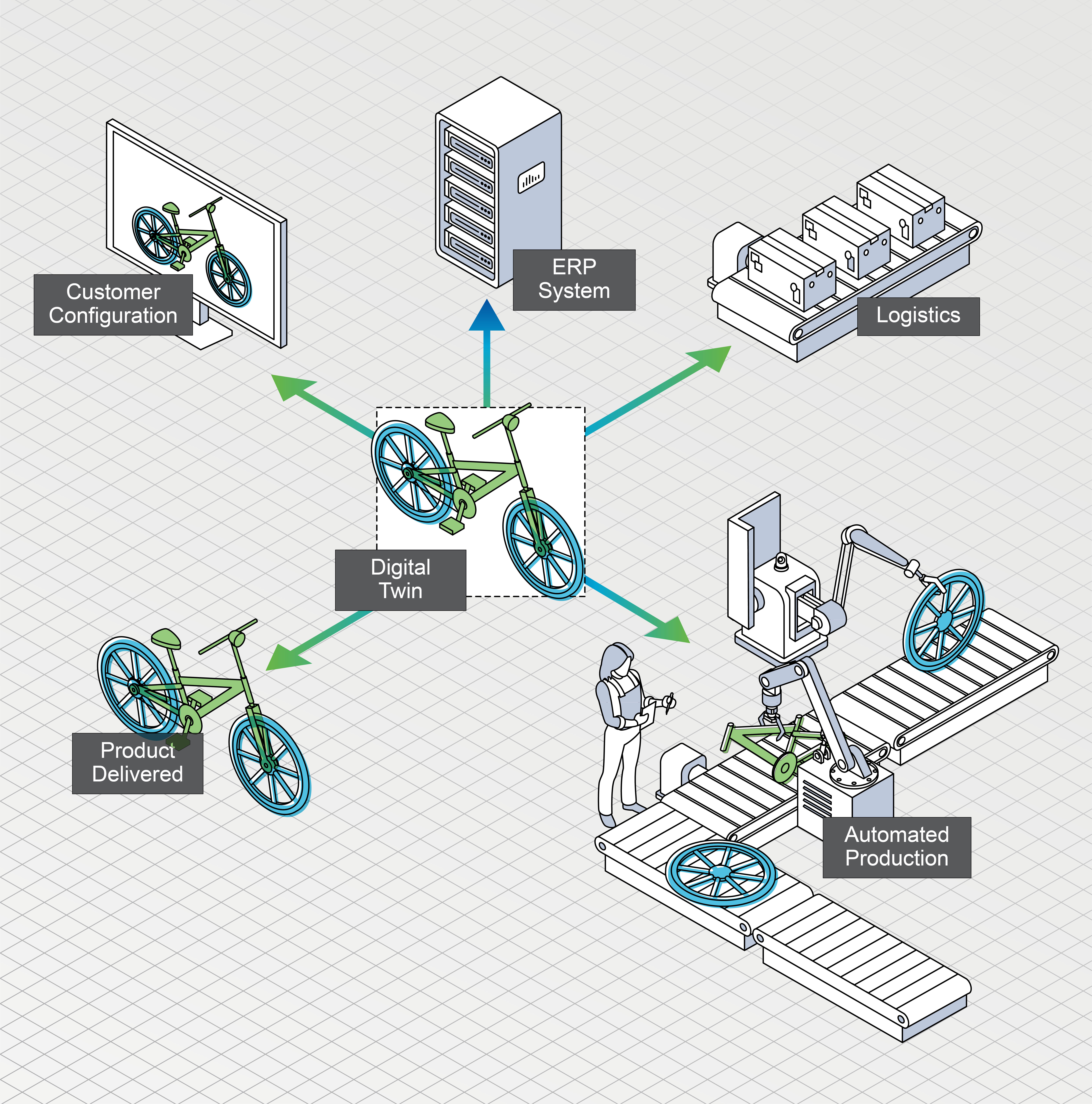

Most bicycle components and industrial processes are being outsourced to factories in Asia. This project explores the added value of “personalised” bikes via a "build-to-order" approach – one possible way to onshore production lines back to Europe. For the bicycle industry, this means that the manufacturing and fulfilment of orders needs to transition from mass manufacturing to flexible assembly in order to satisfy on-demand consumers at scale.

Building social sustainable workplaces through human-robot co-production and assistive technologies

Within this project, researchers and professionals will analyse the industry’s automation potential and implement solutions for human-robot co-production and assistive technologies. A specific focus lies on workers and the enhancement of their physical, sensory, and cognitive capabilities with the help of technology. The goal is to transform the current worker into an Operator 4.0 - someone who is capable of teamwork in and with automatic systems in a design system that’s inclusive towards elderly workers and workers with disabilities.

Wider lessons

The findings from this specific project will generally be applicable to companies that are:

- Reliant on manual labour inside or outside the bicycle manufacturing industry

- Are interested in introducing automated robotic solutions

Societal impacts: robots as workmates

Beyond the wider availability of cargo bikes and their potential acceptance as an alternative mode of transport, what are the implications of this research? On a broader scale, a smart factory approach will foster the demand for inclusive and sustainable workplaces. This requires a responsible innovation approach. With our design approach, which includes multiple stakeholders, it's crucial to involve factory workers in the process.

This project is part of KIC EIT Manufacturing, funded by the European Union.

Doris Aschenbrenner

- +31 (0)15 27 89523

- d.aschenbrenner@tudelft.nl

-

Room B-3-220

Available on: Mon-Tue-Wed-Thu-Fri

"There are 10 types of people in this world, those who understand binary and those who don't"

Joris van Dam

- +31 (0)6 23 55 96 42

- +31 15 27 86870

- j.j.f.vandam@tudelft.nl

-

Room B-0-080

Present on: Tue-Wed-Fri

Neel Nagda

Partners:

- Accell Group

- Chalmers University of Technology

- COMAU

- TU Delft

Jonas Rieder