Education

The Chair of Emerging Materials aims to enrich our students’ vocabulary in materials, support them in understanding, communicating, selecting and designing [with] materials.

In materials education, the following points are taken into account:

- ‘Materials’ is one of the critical subjects in design, which requires constant up-dates on new developments, crossing advancements in material and manufacturing technologies.

- Sensory encounters and hands-on manipulation of materials is a crucial aspect in material learning. ‘Materials’ cannot be understood without sensory exposure.

- Understanding a material requires basic skills and knowledge for technical characterization.

- ‘Materials’ in design cannot be learned based solely on technical/engineering qualities of materials; the materials’ role in creating unique user experiences should be equally involved in design education. Thus, understanding a material in design also requires ‘experiential characterization’.

- In contemporary design discourse, designs are made in the digital domain, whereas the materialization is increasingly done in the physical world by digital tooling (e.g. laser cutting, 3D-printing). In order to materialize their designs for easy and timely validation of their material choices, students should be familiar with advancements in digital tooling and their interrelationships with emerging materials.

Material driven design

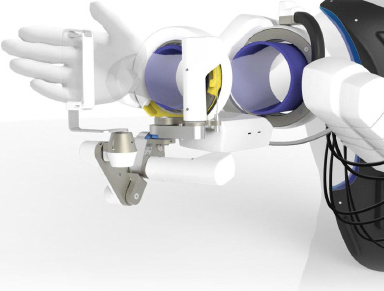

Most of the graduation projects in the Emerging Materials group are linked to our research portfolio and follow the Material Driven Design Method [Karana 2015] in which the students or designers are given a new (smart or biobased) material and are asked to first explore the material’s possibilities and limitations. In the second step they will come up with a material vision and a product concept, which in the last stage of their project they will develop in a functional product or demonstrator.

Graduation projects

We are currently looking for students who are interested to do a graduation project on one of the following themes:

For more information, please contact Kaspar Jansen.

Courses

MSc. Integrated Product Design (Q3 & Q4)

The course Advanced Embodiment Design focuses on the embodiment design phase of the product creation process, which starts from a program of requirements (such as cost, quantity, quality, etc.) and working principles and ends with a validated prototype of a product, which can be physical or virtual as needed. This phase requires the seamless integration of the knowledge of several areas of expertise including theory of embodiment design, ergonomics, product aesthetics and experience, smart systems & technologies, technical concept materialization, sustainable design engineering, and advanced design enablers.

MSc. Elective (Q2)

Materials for Design (MfD) Course is an intrinsically and didactically attractive program with a strong focus on ‘material driven design’ and ‘materials experience’. Students learn a design method to facilitate designing for material experiences when a material is the departure point in the design process. Several projects, workshops and lectures are given to practice the design process when a particular material is the subject of the design effort.

Master Elective (Q3), will start from 2018 Q3

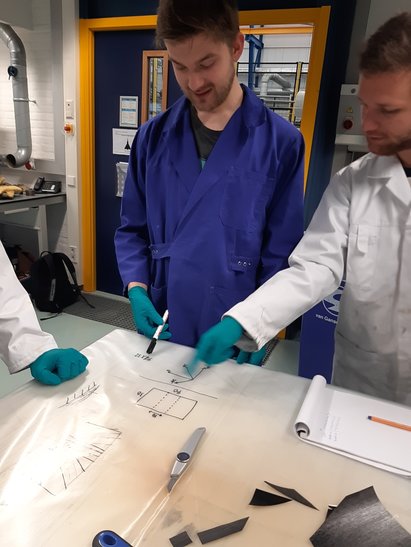

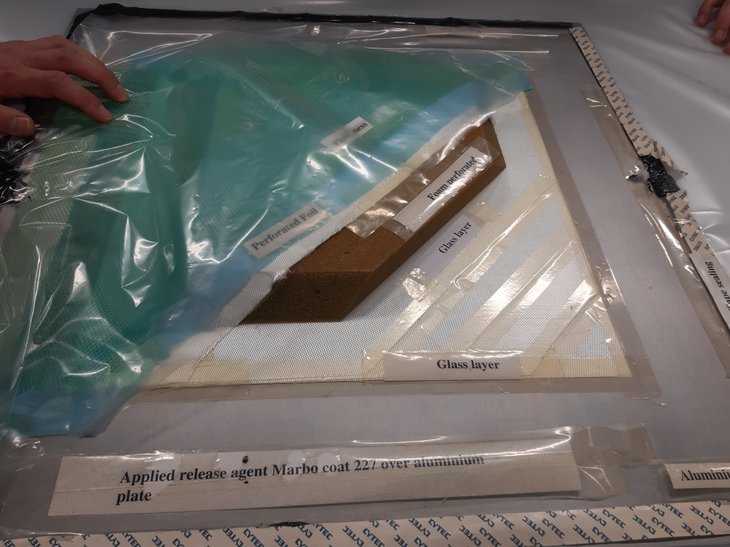

The design, manufacturing and testing of fiber reinforced polymer products. In cooperation with Aerospace Engineering

Coordinators:

The course will start with 4-5 lectures about: Effect of stacking composite layers with different orientation; Classical Laminate Theory; Composite manufacuring methods.

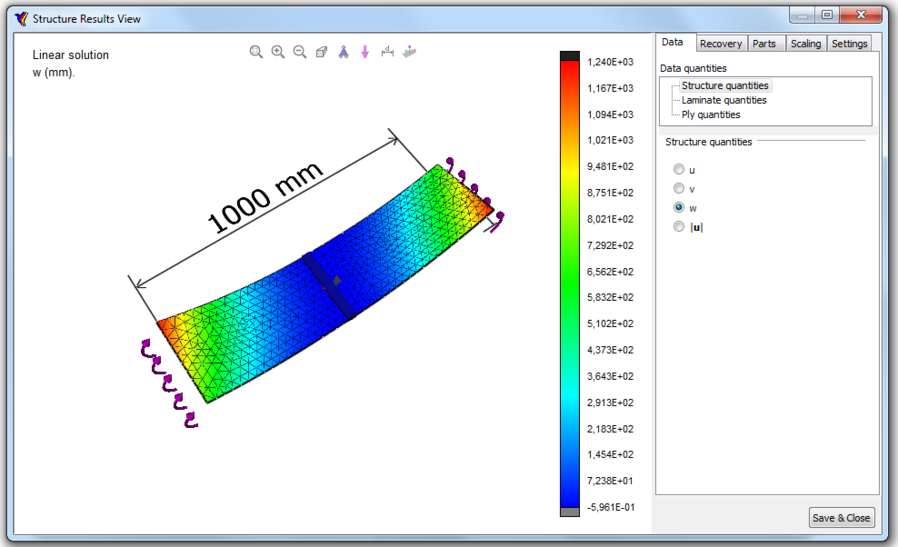

Next the students will be introduced to work with the Kolibri composite simulation program with which they can design a composite product and predict its behavior.

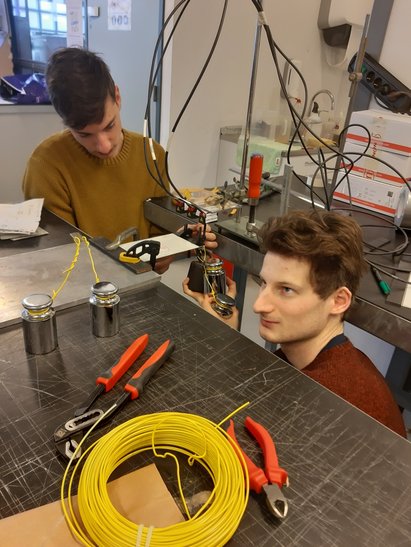

The final parts consists of practical work in which they actual make a simple composite product and verify its performance by testing it. This part will mainly be done at aerospace engineering

More Information