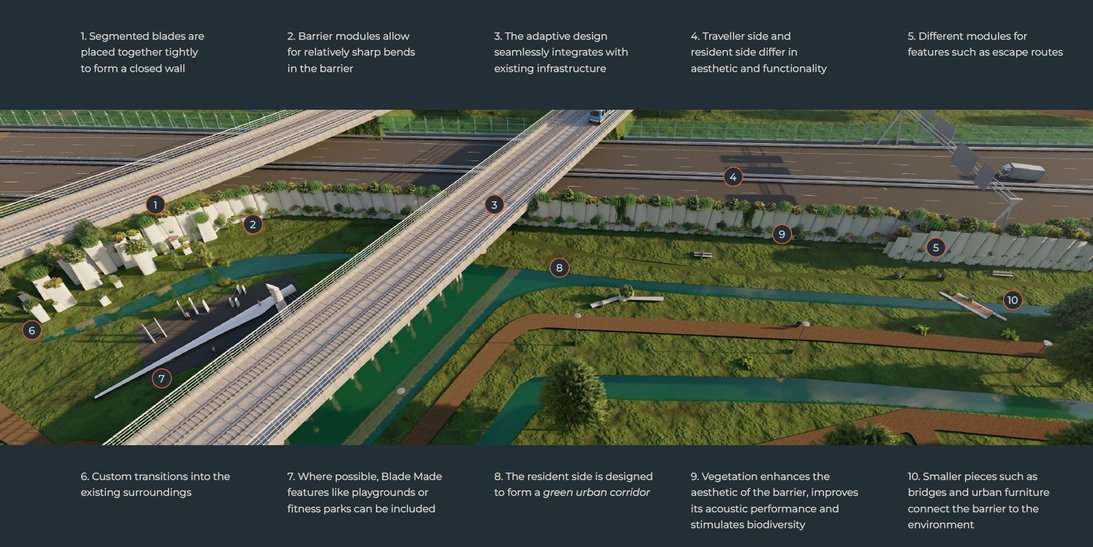

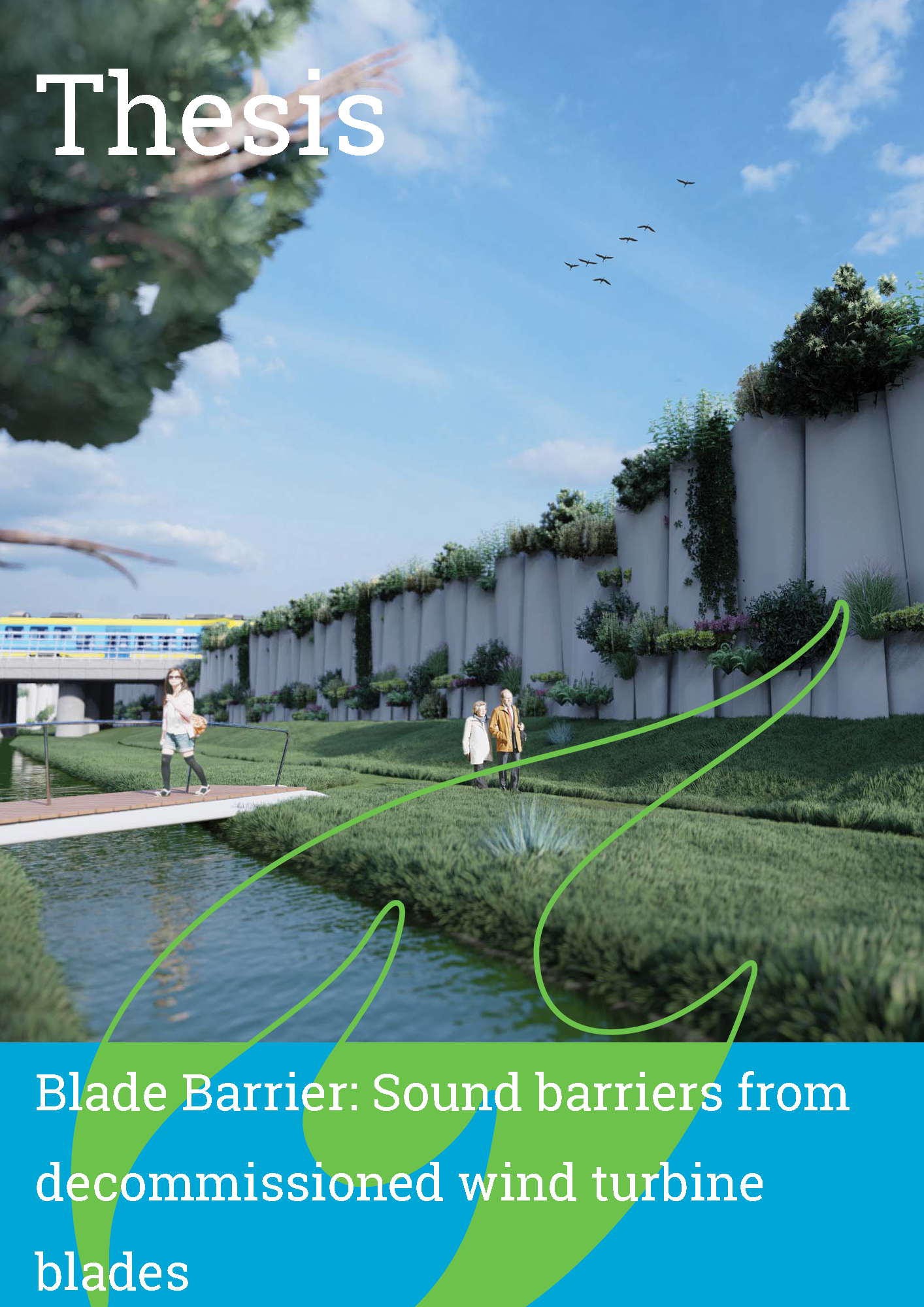

Decommissioned wind turbine blades are very difficult to recycle. But we don’t have to! Their unique properties offer great potential for reuse. The Blade Barrier is a scalable application that functions as a sound barrier, stimulates biodiversity and enhances the user experience on both sides.

Researcher:

Adriaan Przespolewski

Design methodologies:

- Ideation and brainstorming sessions

- Prototyping

- Acoustic simulations

Project type: Master Project

Integrated Product Design

Domain: Product Design

2022

Challenge

When wind turbines reach their end of life, the blades form a waste problem. As the blades are comprised of various materials with strong permanent bonds, they are difficult to separate and recycle. This generally results in the downcycling of the material with inferior properties. Even worse, in many parts of the world, the blades are simply incinerated or landfilled.

Sound barriers do not need to be boring! By reusing existing objects we can create new structures with unique aesthetics, and fulfil multiple purposes simultaneously.

Adriaan Przespolewski

Result

The result is a design for a roadside sound barrier that is adaptive to the availability of blades and the requirements of the barrier location. A roadside sound barrier has the potential to incorporate a large number of blades into its construction. This provides an option to extend the wind turbine blades’ life-in-service for another two to five decades, simultaneously eliminating the need for virgin materials to build a sound barrier.

The only virgin materials in the barrier include concrete, metal and fabric. For some of these components, reused materials can be considered as well, such as concrete with a high concentration of recycled content. The barrier is designed in such a way that all components can be separated at its end of life and used for new applications. In this study I calculated that if decomissioned blades are used to construct 5% of the required sound barriers int he Netherlands, we can nearly eliminate the blade waste steam for that year, and simultaneously vastly reduce the need for virgin materials.

Ruud Balkenende

- +31 15 27 81658

- a.r.balkenende@tudelft.nl

-

Room B-3-310

Maurits Willemen

- +31 (0)6 22228944

- a.m.willemen@tudelft.nl

-

Available on varying days