Facilities

Combustion lab

The combustion test rig at the High-Speed Laboratory (HSL) of the Delft University of Technology has been designed to contribute to the research towards the conception of alternative gas-turbine combustors for low pollutant-emissions. The test-rig is currently able to operate on methane (CH4) and hydrogen (H2). The mixture of the fuel can be exactly defines, by controlled dilution with N2 and CO2. Before entering the combustion chamber, the gasses are pre-heated by a 48 kW heater, which can reach up to 900K at the maximum operating pressure of 10 bar. The combustion chamber is a clear cylinder for optical access, to allow for Particle Image Velocimetry (PIV) of the combustion process. Furthermore, pressure sensors and thermo-couples are located at the combustor exit for instantaneous pressure and temperature measurements.

Low-Turbulence Tunnel

The Low-Turbulence Tunnel (LTT) is a low-speed, closed-return closed-wall wind tunnel with an octagonal test section of 1.80 m width and 1.25 m height. The freestream velocity is up to approximately 100 m/s. At typical freestream velocities for our propeller-integration research of about 40 m/s, the turbulence level is below 0.1% (bandpass filtered between 2 and 5,000 Hz).

A fixed external balance is installed above the test section to allow for measurements of integral forces on the model. A turntable is integrated into the ceiling of the test section to allow for measurements at nonzero angle of attack.

For testing with half models, a separate test section with a 2.055-m long groundboard is available, spanning the entire width of the test section. This ground board represents a symmetry plane for the experimental arrangement, and reduces the height of the test section to 0.995 m. The flow on the groundboard is made turbulent with a transition strip applied at 0.140 m from the board’s leading edge.

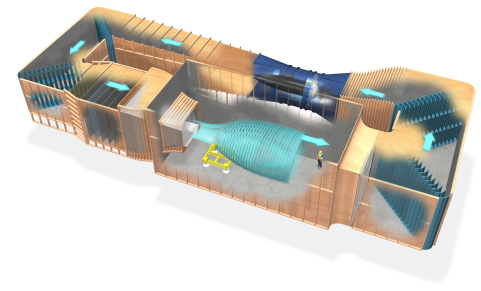

Open-Jet Facility

The Open-Jet Facility (OJF) is a low-speed, closed-return open-jet wind tunnel with an octagonal outlet of 2.85 m width and height. The maximum outlet velocity is approximately 30 m/s. The test section is 6.0 m wide, at a height of 6.5 m and a length of 13.5 m. To remove spatial velocity deviations and to reduce the flow's turbulence level, the settling chamber is equipped with a honeycomb flow rectifier and five screens. This results in velocity deviations smaller than 0.5% in the vertical plane at two meters from the outlet, with a longitudinal turbulence intensity level lower than 0.24%. To reduce acoustic noise levels, the inside of the entire tunnel is covered with perforated plates installed on mineral wood and sound absorbing foam. The fan however does not feature any special noise reduction measures.

The propeller setup is typically installed on a ground plane to minimize the local expansion of the jet and thus provide the most uniform inflow conditions possible.