IRIS

Inverse organic Rankine cycle Integrated System

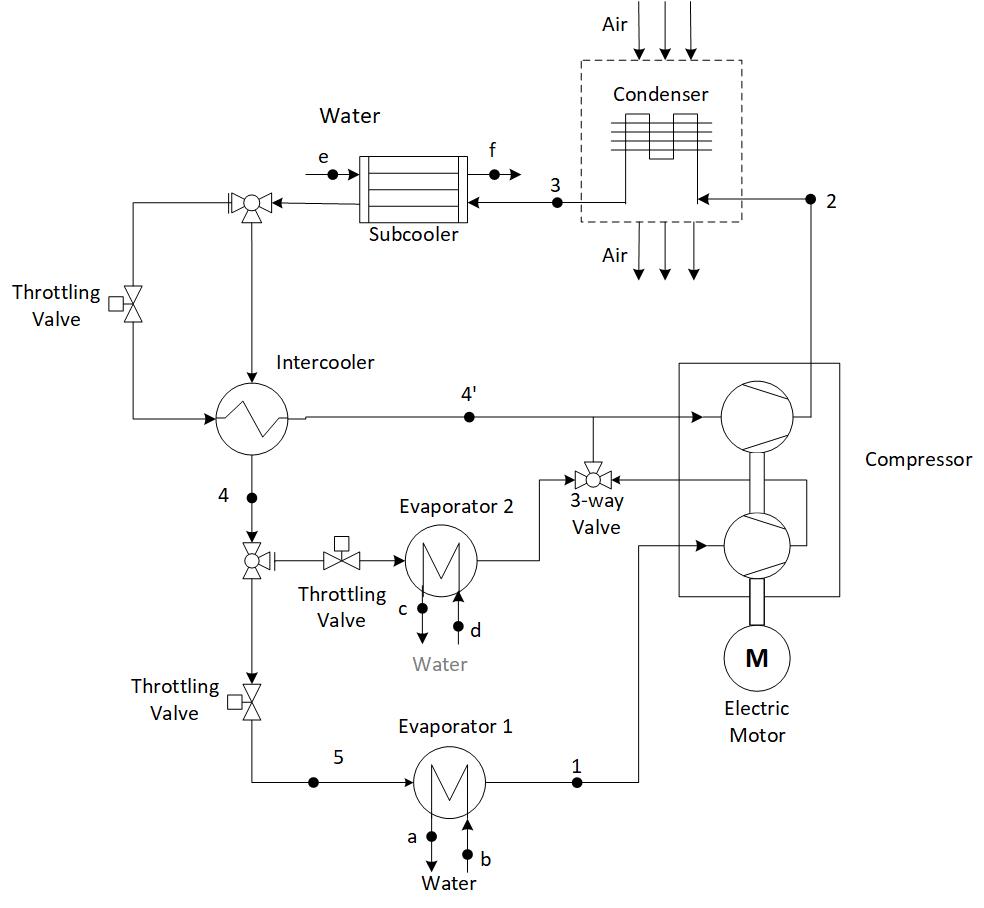

The setup was conceived for the performance analysis and validation of vapor compression cycle (VCC) systems for th Environmental Control System (ECS) of Aircraft. The facility consists in a two-stage compression refrigeration cycle with an intercooler (see process flow diagram). A single Balance of Plant was designed to accommodate two test sections: a high-speed centrifugal compressor testing setup and a condenser test bed. Once steady operating conditions are reached, continuous and simultaneous measurements on both test sections can be recorded. The main components of the setup are:

- a two-stage high-speed centrifugal compressor;

- an air-cooled multi-louvered fins and flat tubes condenser;

- three throttling valves;

- a sub-cooler;

- an intercooler; and,

- two water-to-refrigerant chevron plate evaporators (Evaporator 1 and Evaporator 2), meant for the cabin and the avionics cooling, respectively.

Research needs/objectives

The objectives of the research can be summed up follows:

- Validation of the Modelica system models (static and dynamic);

- Testing of high-speed centrifugal compressors. The results of the experimental investigation will support the validation of CFD models and the development of design and performance evaluation guidelines;

- Analysis of the performances of the air-to-refrigerant condenser, and;

- Testing of a variety of working fluids suitable for ECS, aiming, in particular, to the next generation of low-GWP refrigerants.

Main specifications

- design working fluid: R-1233zd(E);

- condensation temperature: 65 °C;

- evaporation temperature: 0 °C;

- evaporator 1 cooling load: Q̇1 = 15.5 kW;

- evaporator 2 cooling load: Q̇2 = 5 kW;

- evaporators superheating degree: 5 K;

- intercooler thermal duty: Q̇ = 2.4 kW;

- refrigerant mass flow rate: 0.1 kg/s

Planned Experiments

The experimental campaigns will assess the performance of the high-speed centrifugal compressor and the aerothermal characterization of the condenser within the VCC system. Temperature, pressure and mass flow rate measurements have been planned in all the state points of the system. The condenser test section will be instrumented with dedicated measurement techniques on the air side.

The commissioning of the setup is planned for the last quarter of 2021.