MSc programme

Our comprehensive MSc program begins with core courses that provide a solid understanding of the fundamental principles of Materials Science and Engineering. These courses lay the groundwork for your academic journey, equipping you with the essential knowledge and skills required to tackle complex materials challenges.

Following the core courses, you'll have the opportunity to choose a specialisation that aligns with your specific interests and career aspirations. We offer three predefined specialisation, each focusing on a particular subject area within Materials Science and Engineering. These specializations delve deeper into specialized topics, allowing you to gain advanced knowledge and expertise in the relevant field.

Alternatively, you have the freedom to compose your own specialized curriculum. This option provides you with the flexibility to select courses from a wide range of electives, tailoring your studies to match your unique interests and career goals. By customizing your specialization, you can explore interdisciplinary aspects and create a learning path that suits your individual aspirations.

To further enhance your skills and research experience, the program offers the opportunity to undertake a research-based External Research Project as part of your specialization. This project allows you to collaborate with industry partners or research institutions, gaining valuable hands-on experience in a real-world setting. It offers a platform to apply your knowledge, contribute to ongoing research projects, and make connections within the materials science community.

Finally, as you progress through the program, you'll undertake a literature study and engage in an independent scientific investigation. These components form the foundation of your Master's thesis, where you'll conduct original research under the guidance of our faculty members. This thesis is an opportunity to make a significant contribution to the field of Materials Science and Engineering, showcasing your ability to apply critical thinking, research methodologies, and problem-solving skills to address complex materials-related challenges.

Join us at TU Delft and be part of a vibrant academic community, where innovation thrives, and new discoveries shape the future of materials technology.

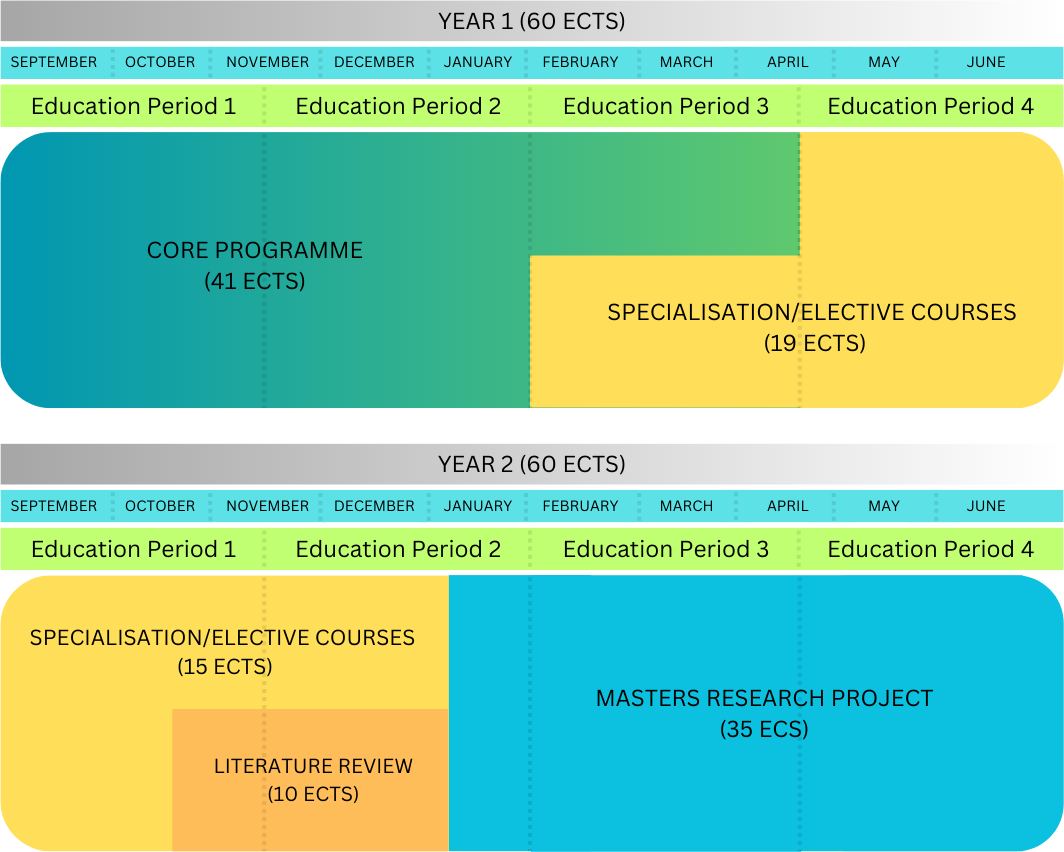

The ECTS (European Credit Transfer System) scheme, for our two-year master’s program is shown below. For more information on the curriculum visit Courses and Specialisation on the “Education” page.