Aquaponics and water purification

Solving three problems using one system: Aquaponics in Cape Town

Minor International Entrepreneurship & Development 2017

Location

Cape Town, South Africa

Students

Jasper van Duffelen

Gerard van Maanen

Harm Minnema

The coming decades the world is facing major issues due to overpopulation since the world population will grow to a staggering 10 billion people. One of these issues is a huge food and water shortage which is predicted to mostly strike Africa. Much research is conducted on this subject but only a few solutions have come up. The Cape Peninsula University is working on a Modular Solar Powered Aquaponics System(MSPAS) which might be the solution to our problems. This system can be used in urban areas to produce food, fish and vegetables, on a small scale to fight world hunger, water scarcity and unemployment in a responsible way.

First a brief introduction to the Modular Solar Powered Aquaponics System:

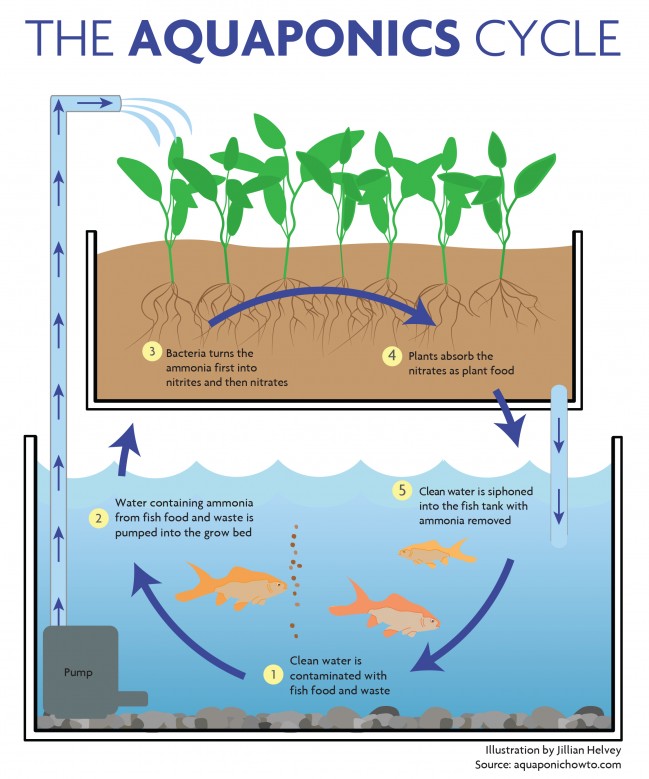

MSPAS consists of two parts: aquaculture, a fish tank and hydroponics, a grow bed for plants. The water of the fish tank is used for the grow bed. Nitrifying bacteria breaks down the by-products of the waste of the fish into nitrate and nitrite. These nutrients are used to grow plants. For this reason fertilizer is not needed anymore. The parts of the plant that aren’t used, are used as food for the fish. The water goes back to the fish tank after it is used for the grow bed, because of this 90% less water is needed for the grow bed. The energy for the system comes from a solar panel and a solar collector.

From the beginning of November 2017 until the end of January 2018 we will be conducting research on the MSPAS at CPUT in Cape Town, South Africa. We are three Dutch students from the TU Delft with various backgrounds, namely Technical policy and management analytics and Civil Engineering.

The project can be divided into two parts: First we will take a closer look at the design of the MSPAS and we will do research on the implementation of a desalination system. Second we will carry out our business plan which includes market research, starting a company and try to serve a customer segment.

Mr Fareed Ismail is conducting research on the MSPAS at CPUT and we will help him during our stay. Furthermore a group of four German students are working on the system for the entire year. Steps to take are improving the efficiency of the system and designing a modular system which can be mass produced. The system can be enhanced with a desalination system, which is being developed by Emad Khatibzadeh and Damon Golriz from De Haagse Hogeschool. The desalination system is a system that can produce clean drinkable water from almost every contaminated water. It can produce up to 10 liters of clean drinking water an hour. We will not test the desalination system in Cape Town, just do research on the possibilities to implement the system with the MSPAS.

The second part will focus on how we can implement the system into society. When we know how we can implement the system and when it is still profitable, we can look for marketing opportunities or other forms of implementation. In that way the community can really benefit from it. During this time, we will go to the community and see the problems and opportunities for the community at first hand. We can tackle the question: is it profitable for communities? Or should we try and find other ways the community can profit from this technology? Such as, letting the community build the systems in the community center and then selling it to Europeans or sell it to schools.

Project Mission

Our mission is to: Create a business for the Modular Solar Powered Aquaponics System to let people produce food in a responsible way.

Organisation

In our project team we have a few members already in Cape Town:

- Fareed Ismail is the leading scientist and inventor of the MSPAS program at the CPUT.

- Christiaan Hartzenberg is the founder and leader of the community center. He wants to help the community with this project and possibly start a business out of it.

- The group of German students is already in Cape Town and is working on optimizing the system.

Activities

The project includes the following actions. A description and an indication of the time spend on it will be given.

Orientation

Having arrived in Cape Town we will spend a week getting to know all the stakeholders involved and ask them about their view on the project. The orientation phase is going to be vastly important to the success of our project since the information about the project delivered in advance is not coherent, slightly contradictory and not complete.

Optimising the MSPAS

From pictures, videos and groups of students we got the impression that the system at this moment is not yet performing at a profitable level. Therefore we have to do research to optimize the system. For instance we can look at the water temperature and maintaining the heat, investigate if the pH levels are correct and if we can make them more constant and work on a larger growbed.

Investigating the integration

We have been asked to investigate if the MSPAS and a desalination system can be combined and if this provides advantages.

Creating a solid business plan

During the orientation we will find out what the exact plans of the stakeholders are and how we can make a business model and solid financial plans with which they can achieve their goals.

Finding Investors

Finding investors will overlap with creating a solid business plan since this is an iterating process. We will look closer into getting financial aid from the government and making appointments with institutions.

Deliverables

- A MSPAS at the community center with a continuous food output and an increased food production.

- A result of market research for future customers. It has to be clear what their needs are and if they are interested in buying or leasing the system.

- Find investors or potential investors for our project.

- A blueprint or idea of a smaller version of the MSPAS.

- A result if the MSPAS and the desalination system can be combined or not. If so, we must find a location for testing in the Western Cape.

- A solid foundation for following groups to build upon.

Potential Significance

- The community center can sell their products and make a profit out of it.

- The result makes clear if it makes sense to sell or lease the system and to build up a business.

- Investors are very important to build up the business. They support our project financially or materially.

- A prototype can be made. A smaller version of the MSPAS addresses to other customers, this result in more sales or lease contracts.

- If it is possible to combine the two systems, students can do experiments in the future. Otherwise it is clear that at the moment it is not useful to do experiments.

- The project can be continued for other students from the TU Delft or The Hague University of Applied Sciences as easy and fast as possible.

To sum up, we are going to work on a promising technique which offers a lot of opportunities. We are looking forward for a wonderful time in Cape Town and reaching our goals.

Results

Every headline describes the result we made during our project in Cape Town between November 2017 and January 2018. Underneath the headline is described for which problem we made a solution and how we solved it.

Secured MSPAS system

Before optimizing the aquaponics system (MSPAS) at the Belhar Community Center, we had to secure the whole perimeter and the system more. The reason for this was that tilapia and spinach got stolen multiple times. The whole perimeter is better secured by reattaching and stretching the old fences, adding a second layer of barbwire on the inner side of the fence, put nails on the top of the poles where the fences are attached to, welded spikes on all the gates and we added two layers op barb wire on top of the gates. The fish tanks and the pump system were secured by wooden pallets, but there was no roof and a lot of gaps between the pallets. To protect the system more, we made a roof on the construction, closed all the gaps between the pallets, put doors in and covered the tunnel with netting and chicken wire. Since we secured the system no more tilapia or vegetables got stolen.

Extra and cleaned grow beds

We transported a grow bed from the Cape Peninsula University of Technology to the community center and connected this to the aquaponics system. With an extra grow bed more vegetables and herbs can be grown, which results in more income. Before we added the extra grow bed to the system, we rinsed and cleaned the stones and rocks in the grow bed first. This will keep the dust from settling on the bottom, which result in mud forms that can make the syphoning less effective. Besides the extra grow bed, the other three grow beds were cleaned as well.

Same amount of nutrients for each grow bed

At the beginning of the project, two fish tanks were filled with fish and the third tank was just water. The fish tank with the most amount of fish was connected to one grow bed and the fish tank with the less amount of fish was connected to two grow beds. We rearranged the fish over the three fish tanks and reconnected the water pipes so every grow bed got the same amount of nutrients.

Reduced algae growth system

In the fish tanks were a lot of algae and the water was too filthy. That is why we cleaned the three fish tanks. To prevent the algae from growing back, the bacteria splosht was added to the sump tank. These bacteria need to be added every two weeks. To prevent algae growth, we made sure no direct sunlight can hit still standing water. Some places in the grow bed had puddles of water, more rocks were added in there to cover these parts. The top layer of a grow bed needs to be dry, to avoid algae growth and a high evaporation rate.

Healed diseased tilapia and caught more tilapia

A few of the tilapia fish got the Fin rot, which is a bacterial infection caused by Flavobacterium Columnare. This disease is common in closed systems and can be recognized on the pink spots on the body of the tilapia. To heal the fish, we first isolated the sick fish from the others, this to prevent any further spreading. We treated the fish with some medicine and after they were cured we put them back into the fish tank that is connected with the grow beds. To prevent further spreading we emptied half of water in the fish tank and refilled it with rainwater.

The tilapia at the moment of arrival (Nov 2017) did not provide enough nutrients for the system, for that reason we caught more tilapia, around 25. The new fish were not immediately introduced to the system, because the caught tilapia may have had a disease. After no sign of disease and after an expert looked at the fish, we decided to put them into the system.

Vegetable and herb selection

A research is done to have a look which vegetables and herbs are the most profitable (in ZAR/m2/month) for an aquaponics system. Mint, basil, rocket (arugula) and baby spinach were the most profitable. For rocket it was not the season when we were in Cape Town (Nov-Jan), because the temperature is too high. We experimented with baby spinach, but most of the plants died. The plants are too fragile for all the changes in the system. Instead of baby spinach we have chosen for normal spinach and lettuce. The problem with herbs is that it can only be used in a niche market. That is why we have chosen for a combination of herbs and vegetables. After the selection a plan is made for the next couple of months (Jan-Apr 2018), this includes when to harvest, the space between the plants and how many seedlings are needed. Also, a mapping is made for each grow bed which vegetable or herb needs to grow there.

Floorplan greenhouse

All the tubes that go from the fish tanks to the grow beds and from the grow beds to the sump tank are glued. To optimize the space in the greenhouse a floorplan is made. At the moment (Jananuary 2018) there are four grow beds in the greenhouse, but this can be more in the future. We changed the positions of the four grow beds, so in the future more grow beds can be placed.

Check on the construction

The roof of the wooden structure that secures the fish tanks and pump system showed a large deflection, therefore it was necessary to calculate whether the roof is safe enough at the moment (January 2018) and in the future when solar panels are put on the structure. After the calculations we found out that the roof is strong enough for now, but if many solar panels are put on top it is highly recommended to reinforce the structure.

Research reduce costs fish food

The Belhar community center only uses commercial fish food. Duckweed can be used as fish food as well for the tilapia, for that reason a research is done about duckweed. The conclusion of this research is that if 50% commercial fish food and 50% duckweed is used, the tilapia growth is more or less the same compared to when only commercial fish food is used. The costs on fish food can be reduced by 50%. The research was based on an experiment from Tavares et al (2008), at the community center this experiment still needs to be done.

First sale and cooperation Pure Good Food

The moment of arrival (November 2017) there was a lot of overgrowing mint in the grow beds and the people from the community center did not know what to do with it. We contacted a company that runs organic cafeterias in Cape Town with a big social aspect, called Pure Good Food and sold all the mint. The first sale ever for the community center. Besides the first sale the owner of Pure Good Food raised money, around 2500 ZAR, as a kick-up start for the community center. Everything the community center grows they will buy.

Logbook and financial plan

The owner of the community center is not a businessman and there was no structure about the measurements of the system, for example temperature level or pH-level. We made a logbook for the community center, so they can write down the temperature, the pH-level, ammonia level and other special occasions every day. The total costs of the system were unknown. We wrote down all the costs made for the system and made an estimation about the income and the return time. We concluded that a solar powered aquaponics can be profitable over time, with a return on investment of around 20%.

Conclusion combining MSPAS and desalination system

In our opinion it is not advisable to combine the desalination system with the MSPAS at the Belhar community center. Combining the systems has only an advantage if photovoltaic panels are used as a source of energy. Furthermore, the systems do not benefit from each other. The water sources available are not 100% suitable for the desalination system and at the moment there is no urgent demand for clean drinking water.

Continuation of the project

In the three months we were in Cape Town (Nov 2017 t/m Jan 2018) we created a structure and a good base to continue the project. The most important thing is to keep the current system running. This means a continuation of planting and harvest; the values need to be checked every day and the fish need to be checked for diseases. Four German students, with who we worked together during our period, will be involved with the project until July 2018. The plan is to use the grow beds as efficient as possible, for this reason more tilapia is needed to provide enough nutrients. If more vegetables and herbs can be grown, more income can be created. With that money more grow beds can be bought, which at the end creates more income again. Another plan for the future are solar panels, which are available from the CPUT and can be put on the roof to reduce the energy costs. The experiment with the duckweed needs to be done to confirm the experiment of Tavares et al (2010), which result in a reduce of fish food costs. The system can still be optimized, but more sales of the vegetables and herbs has the most priority. If the community center can manage that then we see a good future for the community center.

Students: Jasper van Duffelen, Gerard van Maanen and Harm Minnema

Reference

Tavares, F., Roubach, F., Jungles, M., Fracalossi, D., & Moraes, A. (2010). Use of Domestic effluent through duckweeds and red tilapia farming in integrated system