Jonah Poort

Faculty of Mechanical, Maritime and Materials Engineering

Solving Vapor-Liquid Flash Problems Using Artificial Neural Networks

Vapor-liquid phase equilibrium (flash) calculations largely contribute to the total computation time of many process simulation models. These simulations are crucial for the operation and design of many industrial processes e.g. in the chemical industry. As a result, process simulations are limited in the amount of detail that can be included due to time restrictions. In his thesis work, Jonah developed artificial neural networks (ANN) as a much faster and robust alternative to traditional flash calculation methods. It was the first time this had ever been done.

During his internship Jonah worked on the modelling of chemical thermodynamics, and he became very interested in its intricacies, the theory behind it and how to solve these complex equations. His supervisor came up with the idea of using artificial neural networks, and Jonah was eager to take this on as his next challenge. Machine learning, and its application to real problems, turned out to be just as fascinating. He now works as a technical consultant at TNO’s Heat Transfer and Fluid Dynamics group, where he can combine research and applied work. He now focuses on research topics related to the production optimization of geo-energy systems by applying machine learning methods.

Jonah carried out his research independently, with very little supervision needed. It was he who came up with the new idea's, methods etc. and not his supervisors.

Graduation committee - Prof.dr.ir. T.J.H. Vlugt, dr.ir. M. Ramdin, prof.dr.ir. W. de Jong, dr.ir. R. Delfos

Process factories produce many of the products people use on a daily basis, such as food and beverages, cleaning supplies, plastics, and fuels. These factories can be incredibly costly and time-consuming to build. Engineers therefore use process simulation software to estimate the profitability of a factory design before construction. However, such simulation software is founded on complex thermodynamic calculations that are slow to execute, consuming up to three-quarters of the total simulation time.

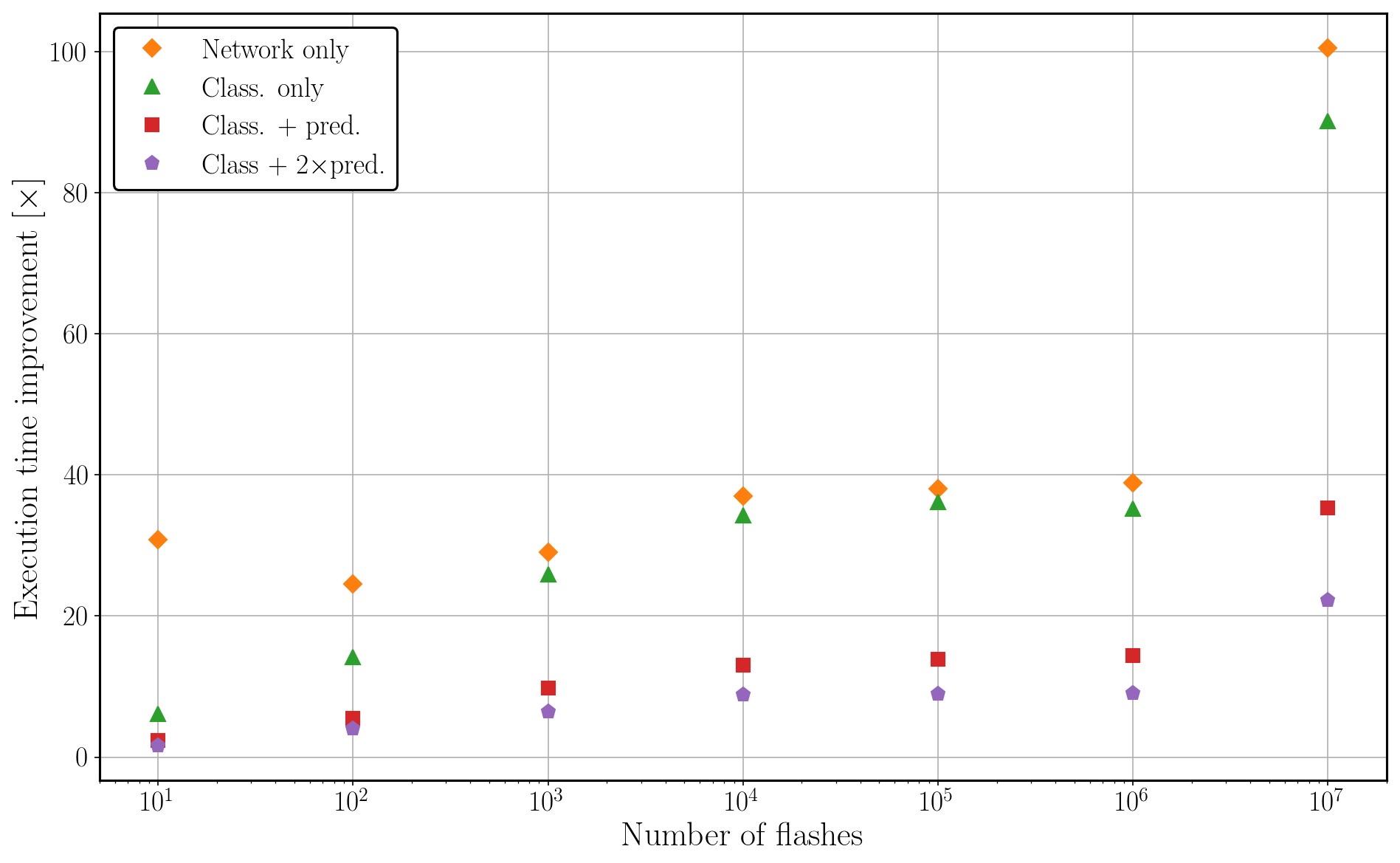

One group of computational methods that are both fast and flexible are Artificial Neural Networks (ANN), which can learn complex input-output relations from a given set of examples. In his thesis, Jonah used ANN to accelerate thermodynamic calculations up to 35 times. In addition, the flexibility of the ANN framework allowed for the development of two new calculation types that had never been performed before, enabling the development of potentially even faster process simulation software