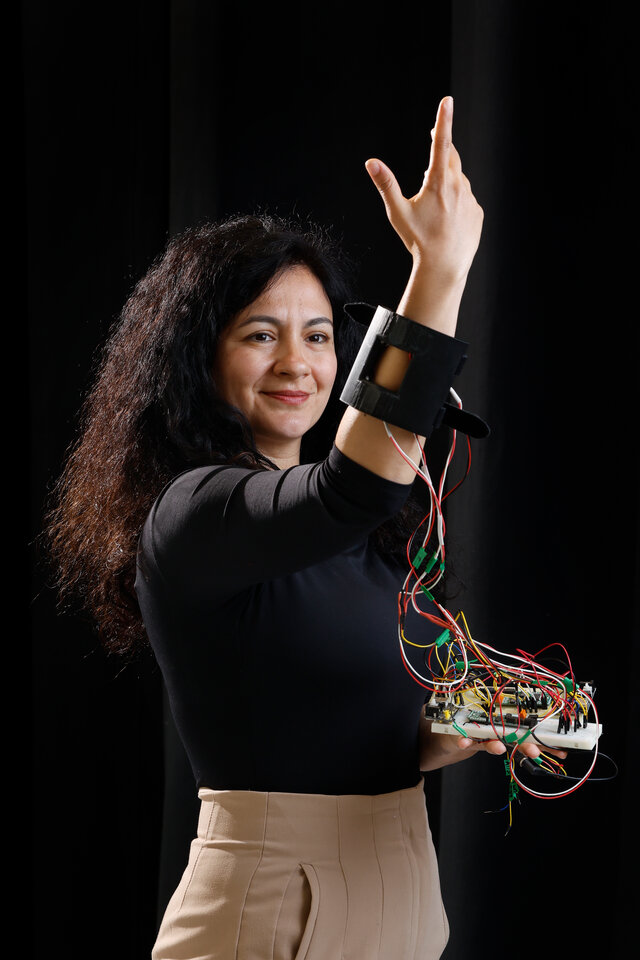

Feeling the digital

Read more Feeling the digital

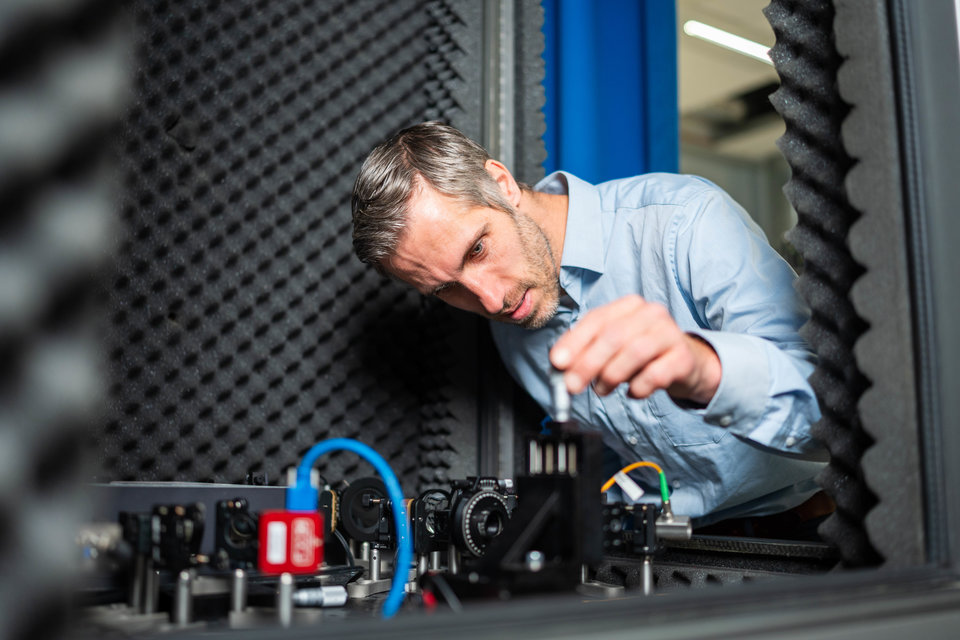

Using sound waves to make microchips and detect faults

Read more Using sound waves to make microchips and detect faults

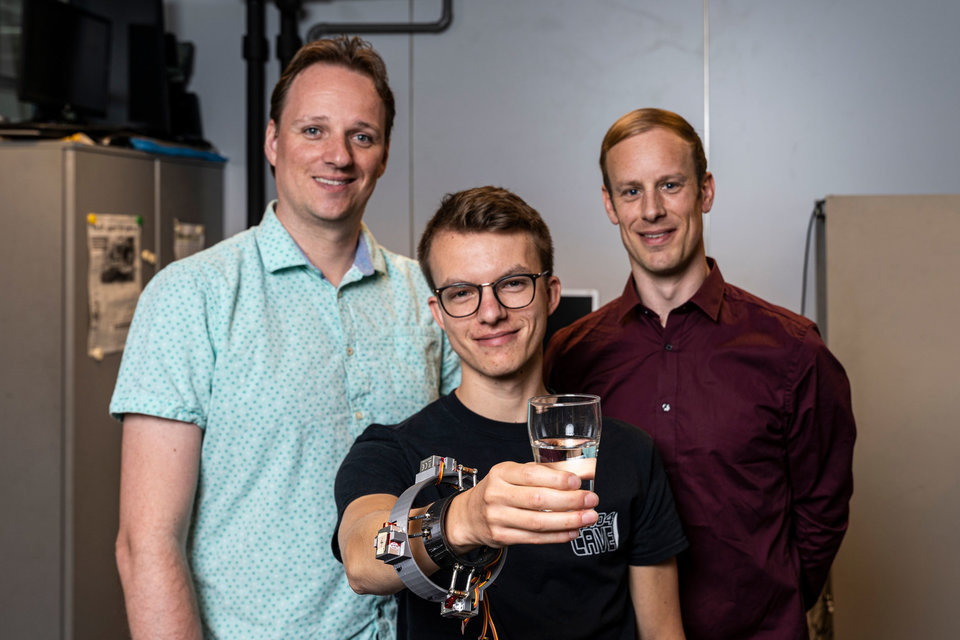

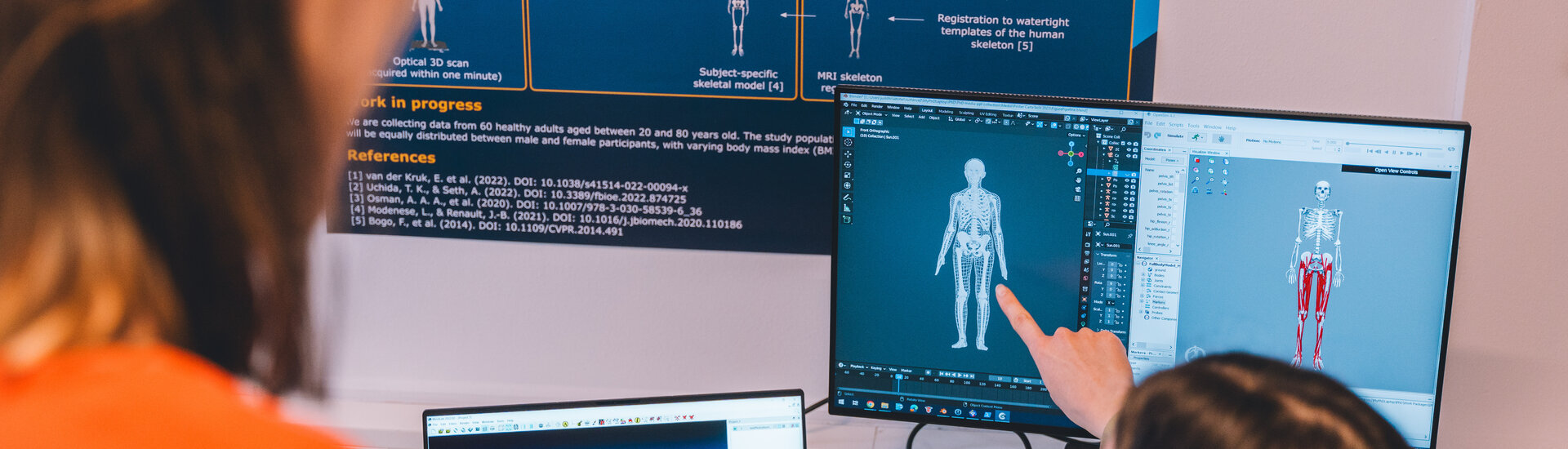

Personalized musculoskeletal models that reflect the diversity of body types

Read more Personalized musculoskeletal models that reflect the diversity of body types

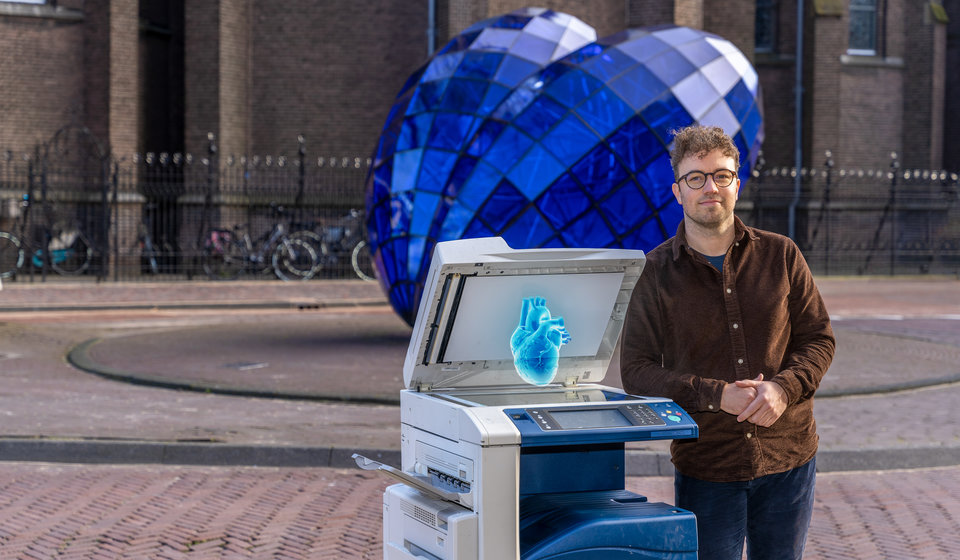

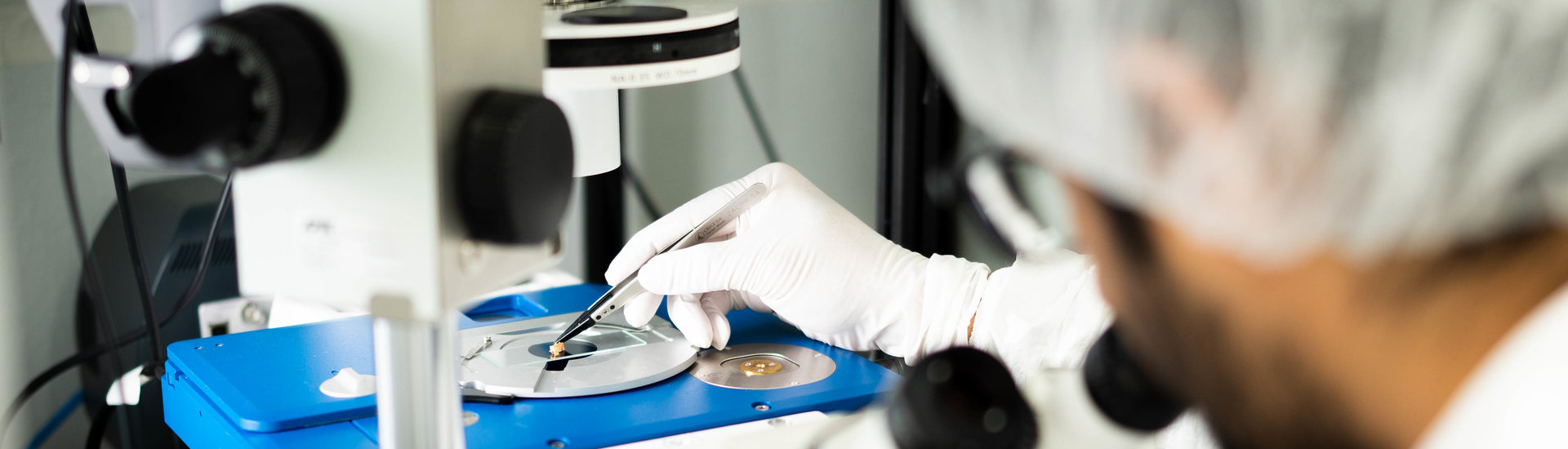

Mechanical engineering at nano-scale requires clean environment

Read more Mechanical engineering at nano-scale requires clean environment

Item 1

of

4