“The major challenge is how to assess the condition of the inside of the fruit. Does the fruit taste good, and is it disease-free?”

Food waste is one of the greatest economic and ethical challenges of this age. It is estimated that one third of world food production is wasted every year, with an estimated economic value of 1 trillion euros a year. In Europe alone, every person wastes an annual average of 200-260 euros of fruit and vegetables. Inefficiency on this scale is only found in the food industry.

A large amount of fruit and vegetables perishes during transport and distribution. Quality control processes are still often random and their accuracy is highly limited. Random sampling results in entire batches being rejected, containing both acceptable and damaged fruit and vegetables.

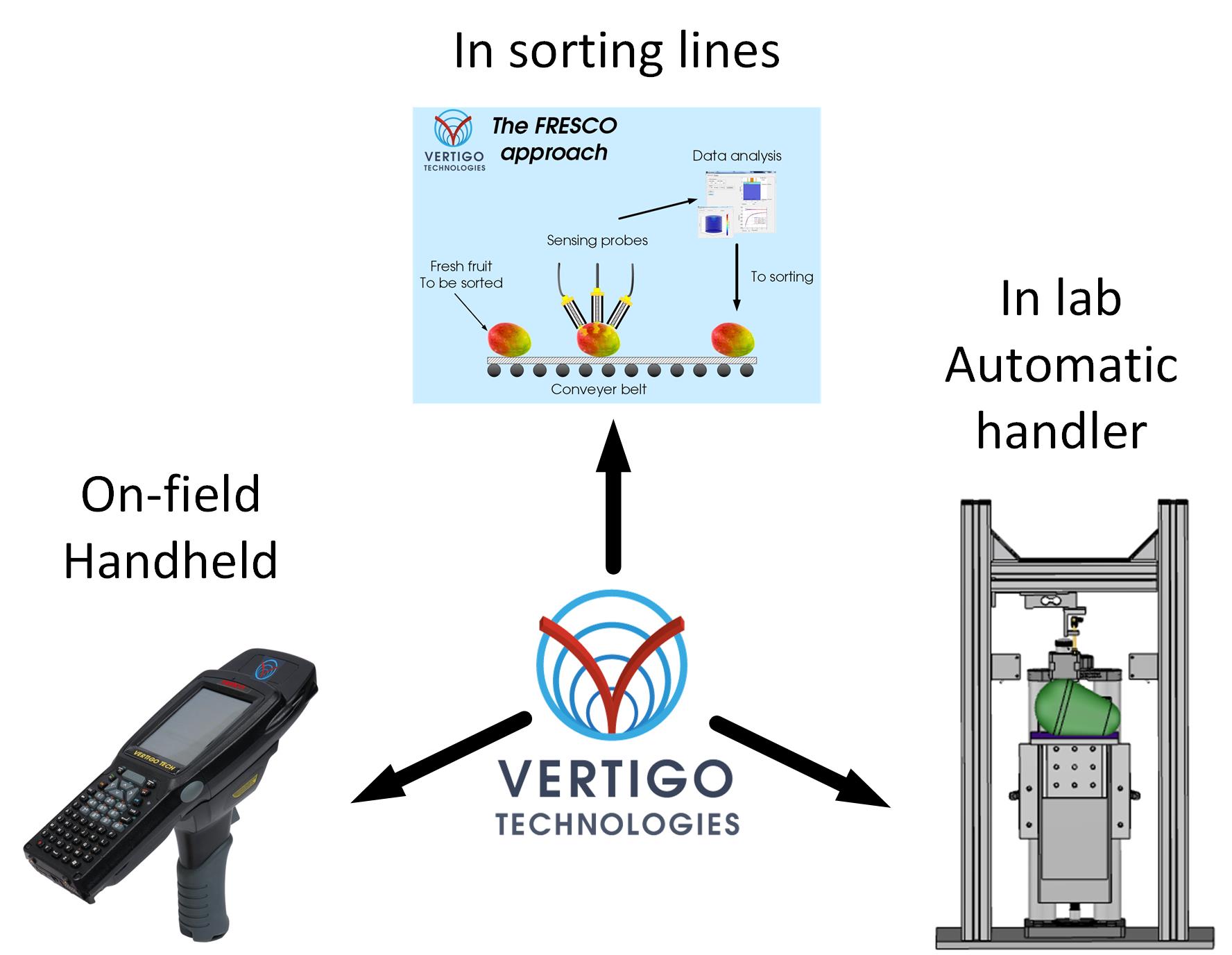

Automated quality controls would reduce this wastage. The ability to check every vegetable or piece of fruit would be the ultimate breakthrough. Sorting processes, equipped with a variety of sensors, are already capable of assessing the outward appearance of fruit and whether the fruit is sufficiently ripe. But the major challenge is how to assess the condition of the inside of the fruit. Does the fruit taste good, and is it disease-free?

Qualitative information can be obtained using dielectrical measurement techniques developed by TU Delft, such as microwave screening and deep learning. It would then be possible to determine at an early stage whether all important characteristics of the crop – such as e.g. ripeness, water content and sugar content – are up to scratch.

This approach is focused on reducing wastage throughout the entire chain. From farm to distribution centre, from breeders to supermarkets: the approach can be used everywhere to constantly monitor the quality of fruit and vegetables.

For more information: https://vertigo-tech.com/services/fresco/